A biological treatment accelerator for coking wastewater

A technology for biological treatment and coking wastewater, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as low treatment efficiency, microbial inhibition or poisoning, and achieve biological utilization The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

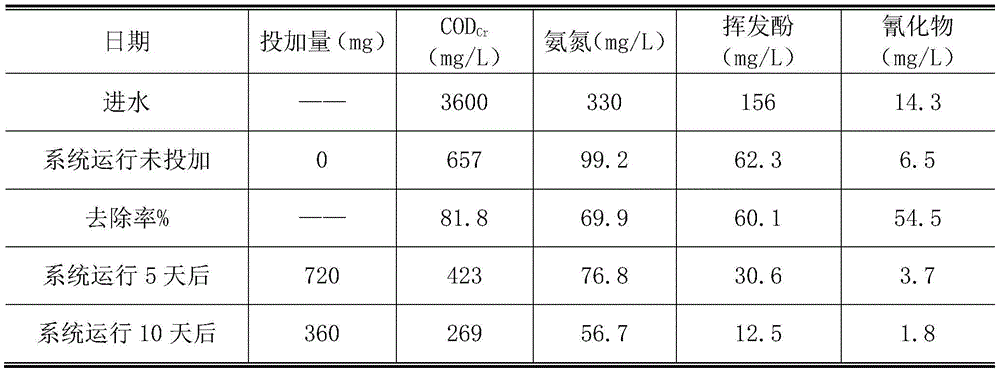

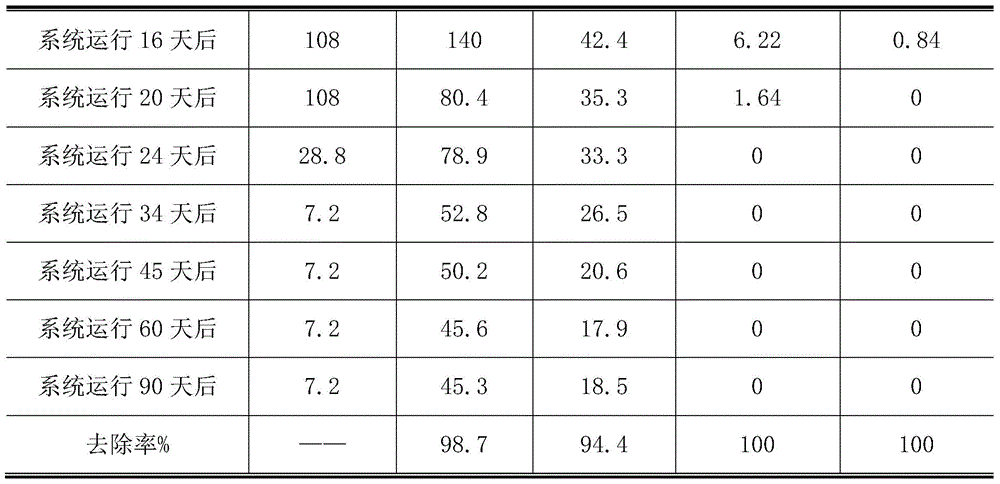

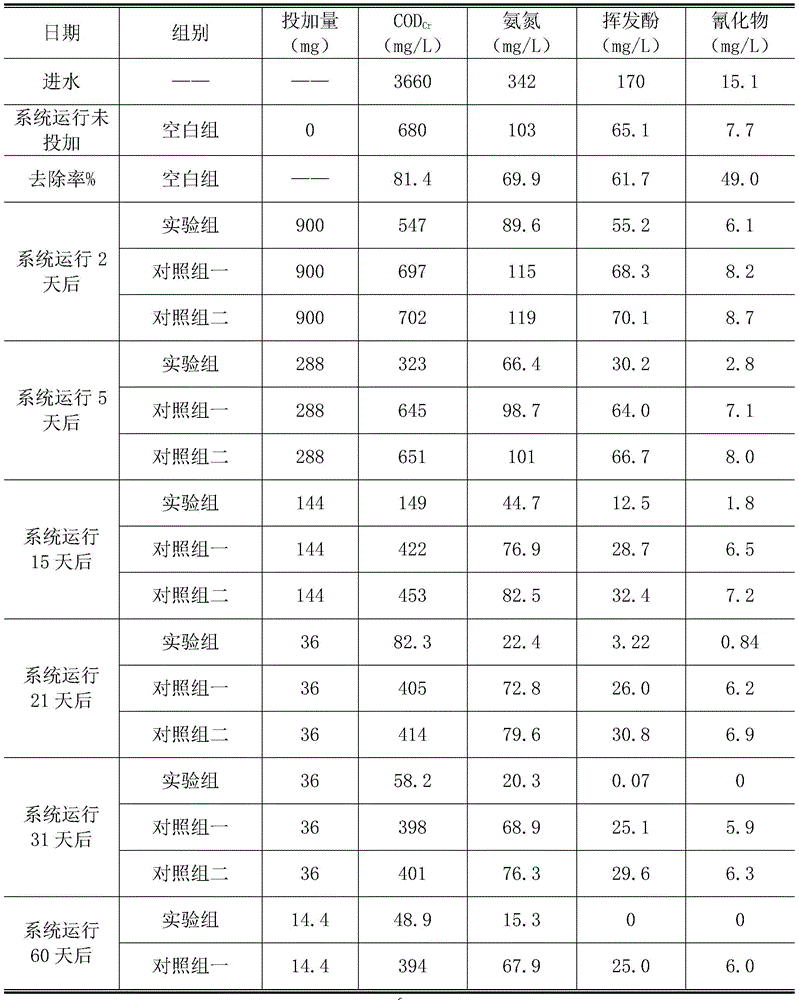

Examples

Embodiment 1

[0040] Example 1: Preparation of coking wastewater biological treatment accelerator

[0041] Take 42 kilograms of glucose, 22 kilograms of zinc acetate, 18 kilograms of potassium acetate, 8 kilograms of ammonium dihydrogen phosphate, 4 kilograms of magnesium chloride, 3 kilograms of iron sulfate, and 3 kilograms of vitamin B6. After the above raw materials are pulverized and mixed, a coking wastewater biological treatment accelerator is made. , to detect the package.

Embodiment 2

[0042] Embodiment 2: Preparation of coking wastewater biological treatment accelerator

[0043] Take 40 kg of glucose, 25 kg of zinc acetate, 20 kg of potassium acetate, 6 kg of ammonium dihydrogen phosphate, 3 kg of magnesium chloride, 4 kg of ferric sulfate, and 2 kg of vitamin B6. After the above raw materials are pulverized and mixed, a coking wastewater biological treatment accelerator is made. , to detect the package.

Embodiment 3

[0044] Embodiment 3: the preparation of coking wastewater biological treatment accelerator

[0045] Take 35 kilograms of glucose, 30 kilograms of zinc acetate, 15 kilograms of potassium acetate, 10 kilograms of ammonium dihydrogen phosphate, 8 kilograms of magnesium chloride, 7 kilograms of iron sulfate, and 5 kilograms of vitamin B6. After the above raw materials are pulverized and mixed, a coking wastewater biological treatment accelerator is made. , to detect the package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com