Automatic wire cladding method suitable for adhesive long wire cake and wire cladding machine

A wrapping machine and silk cake technology, which is applied in the field of viscose filament spinning, can solve the problems of low success rate of suction cups and suction bags, messy wire loops, and operation affecting packaging effects, etc., and achieves simple structure, neat wire loops, Fully open pocket effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

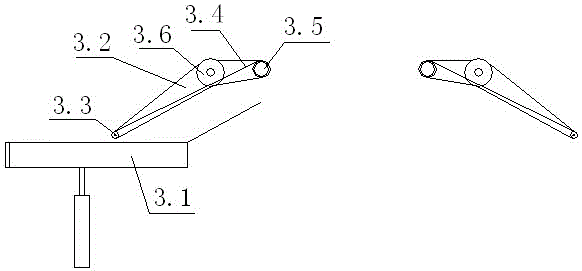

Image

Examples

Embodiment 1

[0055] A kind of automatic wrapping method that is applicable to viscose filament silk cake of the present invention, comprises the station (or step) that implements this method as follows:

[0056] (1) Bag taking and opening station: it is used to stick the two sides of the opening end of the packaging bag (thin non-woven fabric packaging bag for packaging silk cake, open at both ends) and send it to the

[0057] (2), Packing bag bagging, rotation, and bagging preparation station: Stretch and fix the bag that is stuck on both sides of the opening end in step (1) and stretched out, rotate to set the angle, and wait for bagging (waiting silk cake into the packaging bag);

[0058] (3) Silk cake conveying station: used to intermittently convey the silk cake to the predetermined position;

[0059] (4) Picking, transferring, and pushing stations: Take away the silk cake at the predetermined position, and transfer it to the position corresponding to the opening of the packaging bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com