Crawler-type telescopic hedge pruning machine

A telescopic tree and crawler-type technology, applied in agricultural machinery and implements, hedge trimming equipment, cutting tools, etc., can solve problems such as inconvenient operation and insufficient pruning personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

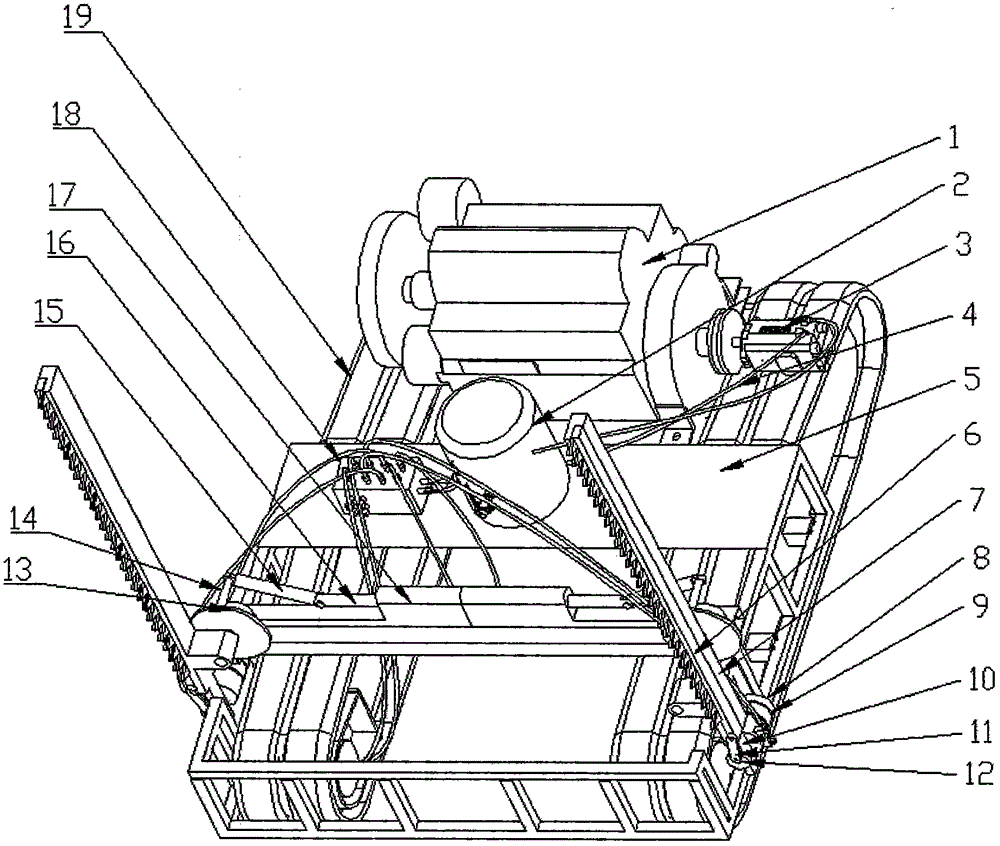

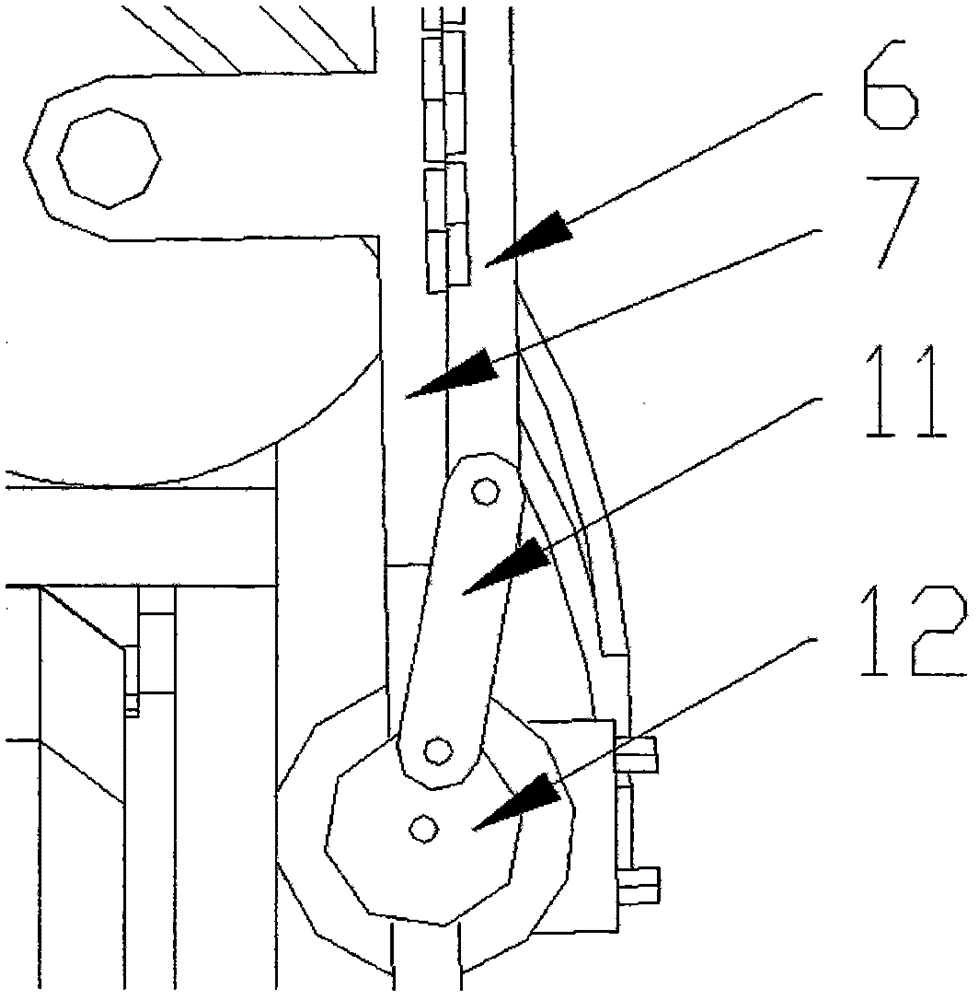

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] see Figure 1-2 , the crawler-type retractable hedge trimming machine of the present invention includes a self-propelled machine 19 and a fixed bracket 5 symmetrically distributed along the crawler belt of the self-propelled device, and a crank linkage mechanism fixedly connected to the fixed bracket 5, and The crank-link mechanism is fixedly connected together with the fixed bracket 5 through the hydraulic cylinder (comprising the hydraulic cylinder piston 16 and the hydraulic cylinder housing 17), the crank 13 respectively, one end of the rocking rod 15 is fixedly connected with the hydraulic piston 16, and one end is connected through the Axle 14 is fixedly connected with crank 13; and the reciprocating motion of described hydraulic piston 16 in hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com