Magneto-optical detection device

A detection device, magneto-optical technology, applied in the direction of optical testing flaws/defects, polarization influence characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

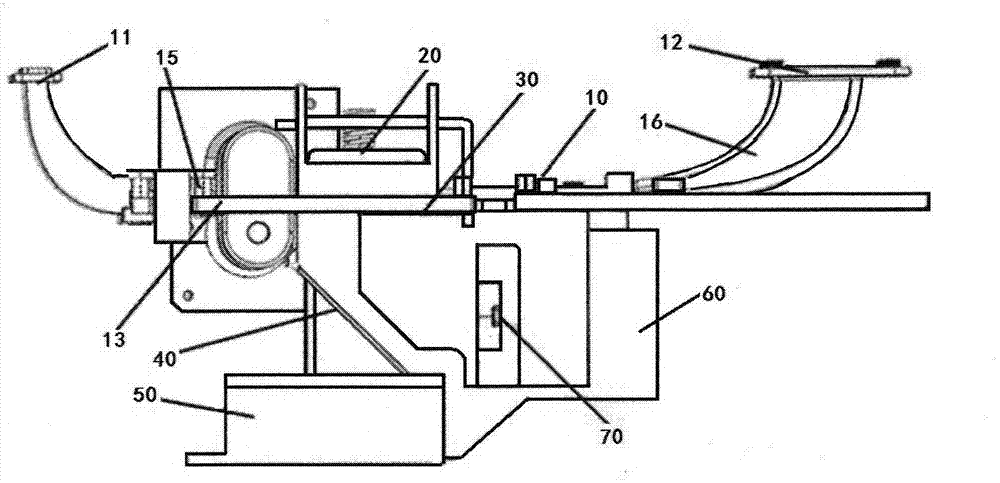

[0019] Such as figure 1 As shown, the present invention relates to a magneto-optical detection device, which includes a magnetic stripe moving mechanism 10, and the magnetic stripe moving mechanism 10 includes a magnetic stripe inlet 11 and a magnetic stripe outlet 12, and the magnetic stripe inlet 11 and the magnetic stripe outlet There is a magnetic strip moving path 13 between 12; on the moving path, a pressing plate 20 is arranged, and a magneto-optical film 30 is arranged below the moving path 13 and facing the position of the pressing plate 20, and the magneto-optic film 30 A spectroscopic sheet 40 , a polarized light source 50 and a camera 60 are arranged below. The polarized light source 50 is composed of a plane light source and a linear polarizer. The magneto-optical detection device also includes a single-chip microcomputer for controlling the polarized light source 50 , the magnetic strip moving mechanism 10 and the camera 60 . In the present invention, the camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com