Oil conveying device of vehicle automatic transmission

A technology for automatic transmission and oil delivery, which is applied to transmission parts, transmission components, components with teeth, etc., can solve the problems of energy waste and increase the cost of automobile use, and achieve improved power transmission efficiency, fuel efficiency, and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

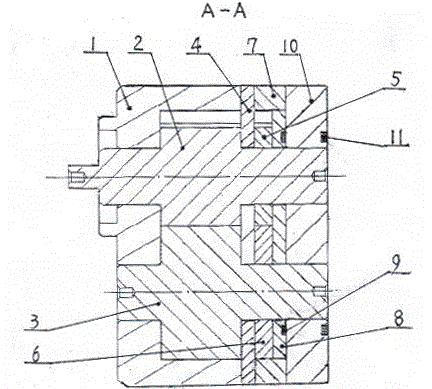

[0011] Examples, see attached Figure 1~3 The housing one 1, the partition plate 4, the housing two 7 and the upper end cover 10 of the vehicle automatic transmission oil delivery device are positioned through two relative positioning sleeves 12, and the two bolts 13 respectively pass through the positioning The central hole of the sleeve 12 is threadedly connected with the shell one 1 , and the shell one 1 , the partition plate 4 , the shell two 7 , and the upper end cover 10 are axially tightly connected. The partition plate 4 is provided with a partition plate oil discharge passage 4-1, the casing two 7 is provided with a casing two oil discharge passage 7-1, and the upper end cover 10 is respectively provided with an end cover oil discharge port one 10-1 It communicates with the oil discharge port 2 10-2 of the end cover, the oil discharge channel 4-1 of the partition plate, and the oil discharge channel 7-1 of the housing 2 in correspondence with each other. Drive gear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com