A two-station rotary table

A rotary table, two-station technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of difficult control of working speed, oil leakage of hydraulic cylinders, and high hardware cost, and achieves simple structure and noise. Small, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

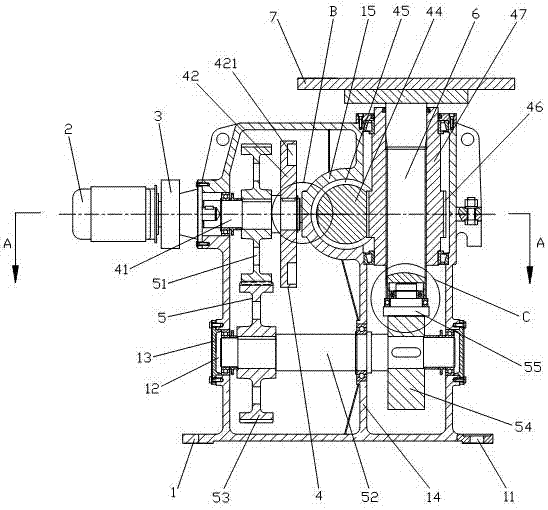

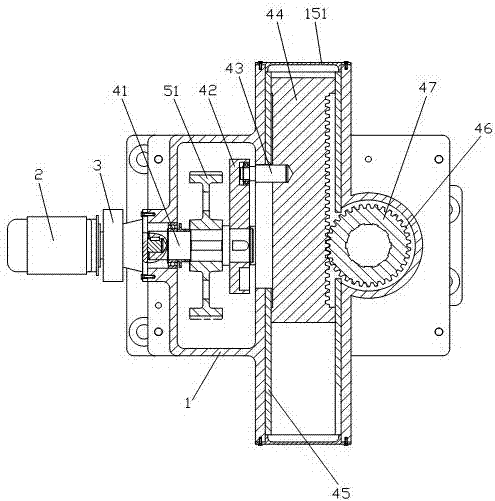

[0018] Such as Figures 1 to 4 As shown, the two-station rotary table of the present invention includes a cabinet 1, a motor 2, a reducer 3, an indexing mechanism 4, a lifting mechanism 5, a rotating shaft 6 and a table top 7.

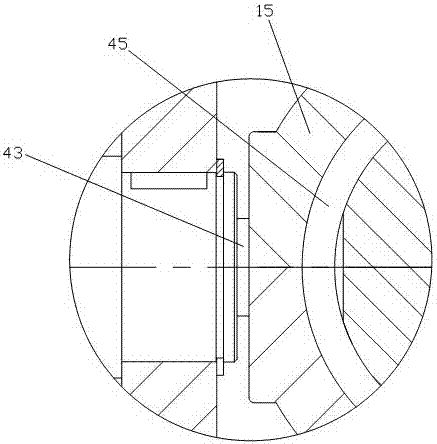

[0019] The periphery of the bottom end of the case 1 is provided with a case installation hole 11, and the middle and lower end is symmetrically provided with transmission shaft installation holes 12 on the opposite side walls, and a transmission shaft protective end cover 13 is installed at the outer end of the transmission shaft installation hole 12; 1. The interior is divided into two left and right chambers by the support wall 14. The upper end of the support wall 14 is horizontally connected with a rack installation pipe 15; the rack installation pipe 15 is located in the left chamber of the chassis 1, and its two ends The nozzles are respectively closed by the end caps 151 of the rack installation tubes;

[0020] The motor 2 is mounted on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com