Flexible forming machine for total assembly of vehicle models for air storage

A technology for forming machines and vehicle models, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high manufacturing cost, increased investment cost, hidden safety hazards, etc., and achieves flexible and convenient operation, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

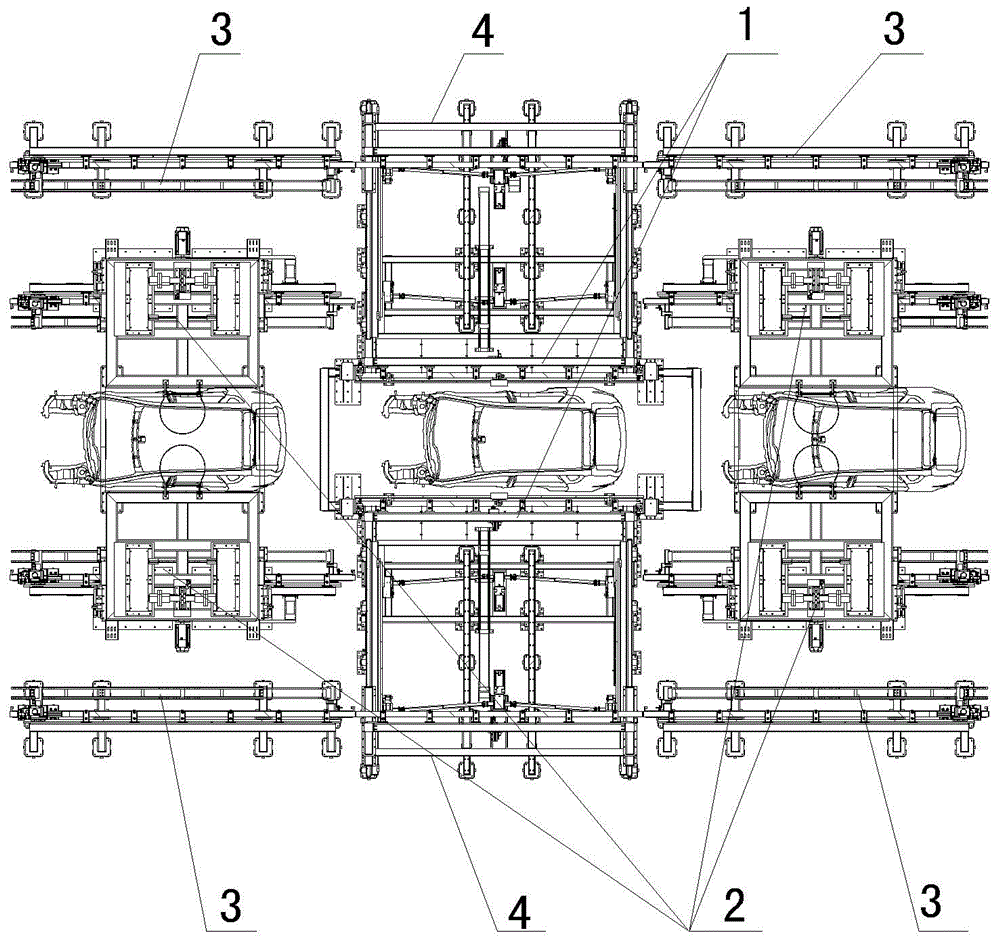

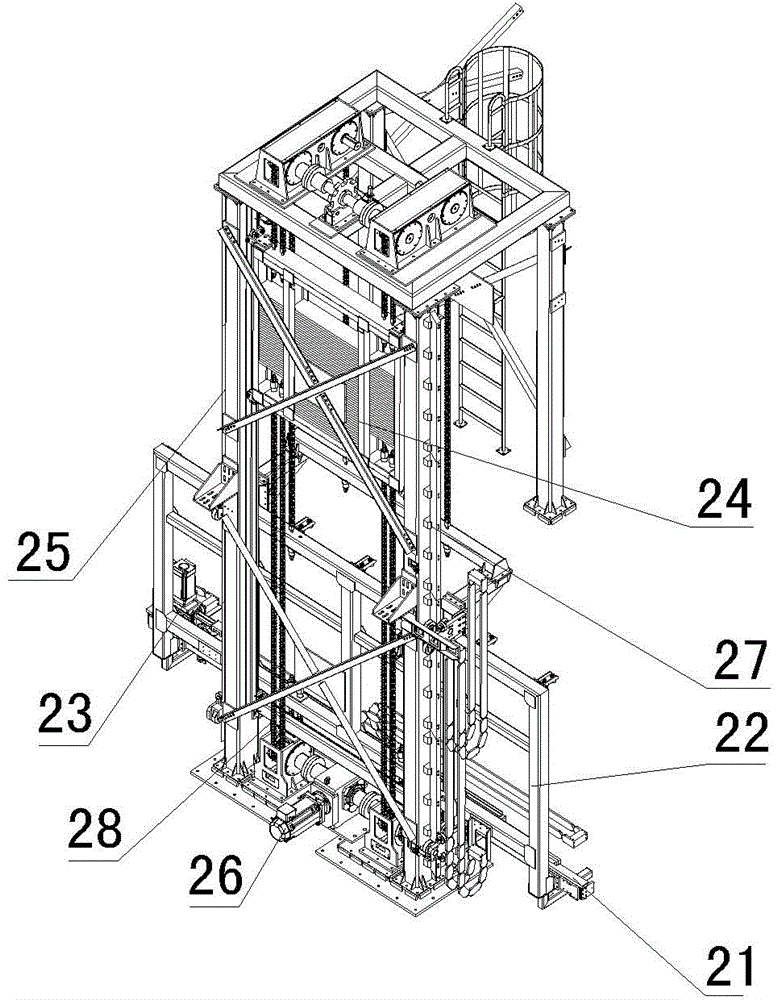

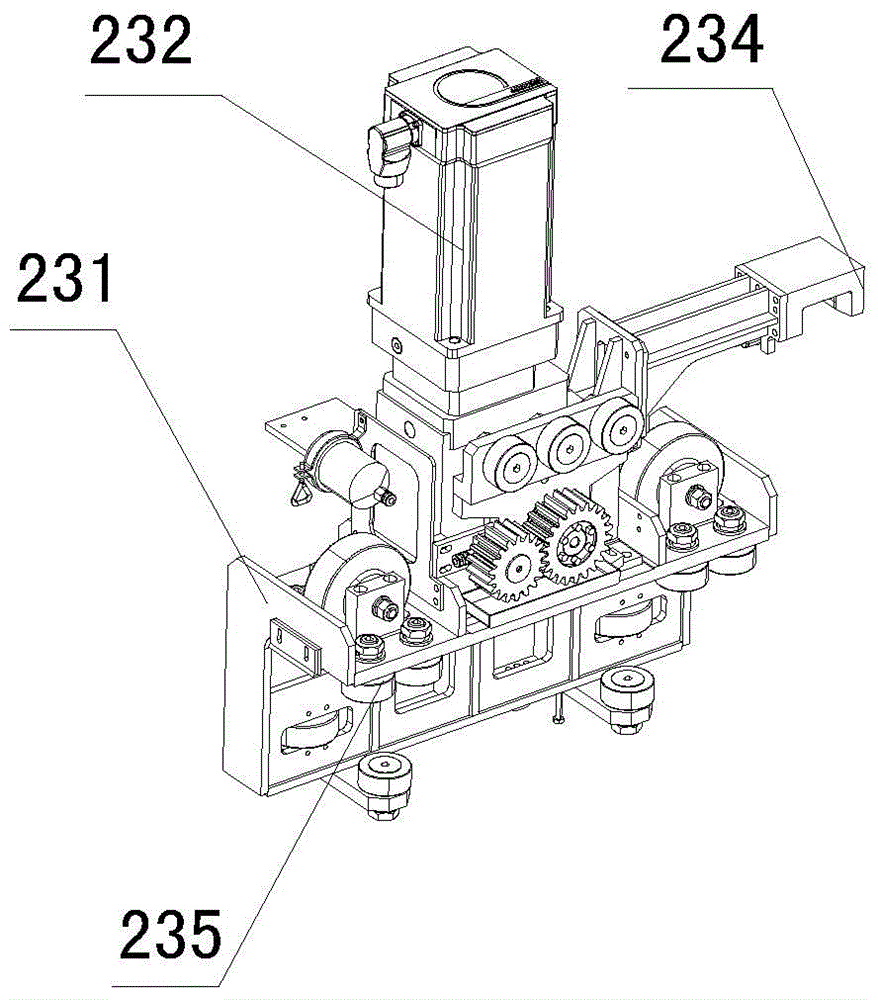

[0042] Such as figure 1 As shown, the car model assembly flexible molding machine stored in the air of the present invention includes a central positioning mechanism 1 and a fixture storage mechanism. The area between two sets of symmetrically arranged central positioning mechanisms 1 constitutes a car assembly and welding station, and the fixture storage mechanism includes lifting and storage. Warehouse 2, fixed storage warehouse 3 and track switching mechanism 4, two sets of lifting storage warehouse 2 and fixed storage warehouse 3 are respectively arranged on both sides of the central positioning mechanism 1, and are symmetrical along the automobile conveying roller in the automobile assembly and welding station, and fixed The storage warehouse 3 is located outside the lifting storage warehouse 2 , and the track switching mechanism 4 is arranged above the central positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com