Detachable combined anti-misoperation locking box suitable for power transformation protection screen

A technology that prevents misoperation and protects the screen. It is applied in the direction of the board/panel/desk of the substation/switchgear. It can solve the problems of mistakenly touching the pressure plate of the operating equipment, affecting the accuracy, and potential safety hazards, so as to avoid changes and quickly disassemble and assemble. Accurate and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

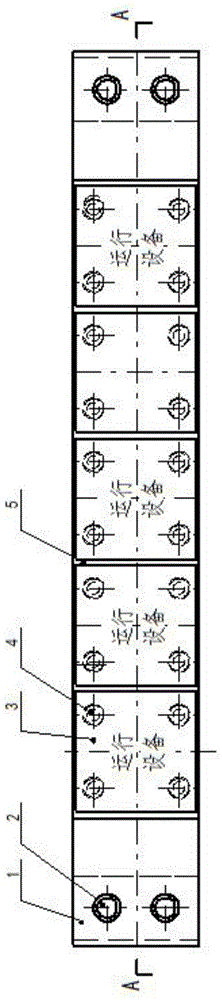

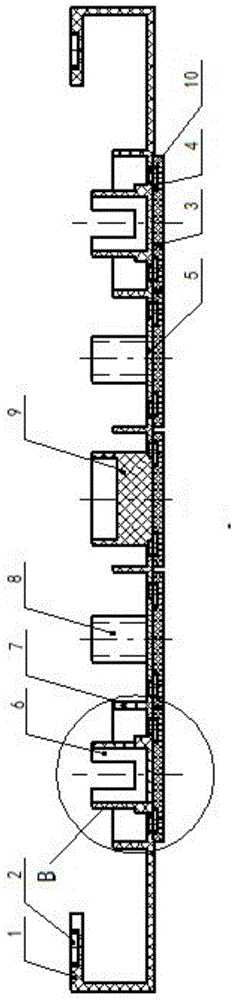

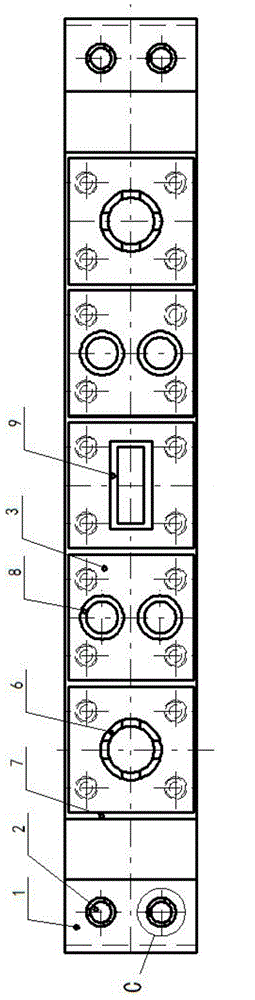

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. It should be noted that this embodiment is illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0020] A detachable combination anti-misoperation locking box suitable for power substation protection screens, including a box body 5 and a warning plate 3, the box body is a positioning plate 1 that is mirror-symmetrical on both sides and vertically recessed inward, on the positioning plate A positioning magnet 2 is embedded through the mounting hole, and the positioning magnet is fixed in the positioning pressure plate through the interference protrusion 11 made on the inner edge of the mounting hole in an interference manner; in the box between the positioning plates The height-limited square frames 7 are uniformly distributed at intervals, and a plurality of secondary element locking sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com