A laser method for reducing heat load and wave resistance caused by type IV shock waves

A shock wave and laser technology, applied in optics, optical components, instruments, etc., can solve the problems of reducing ballast and heat load, taking into account wave resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

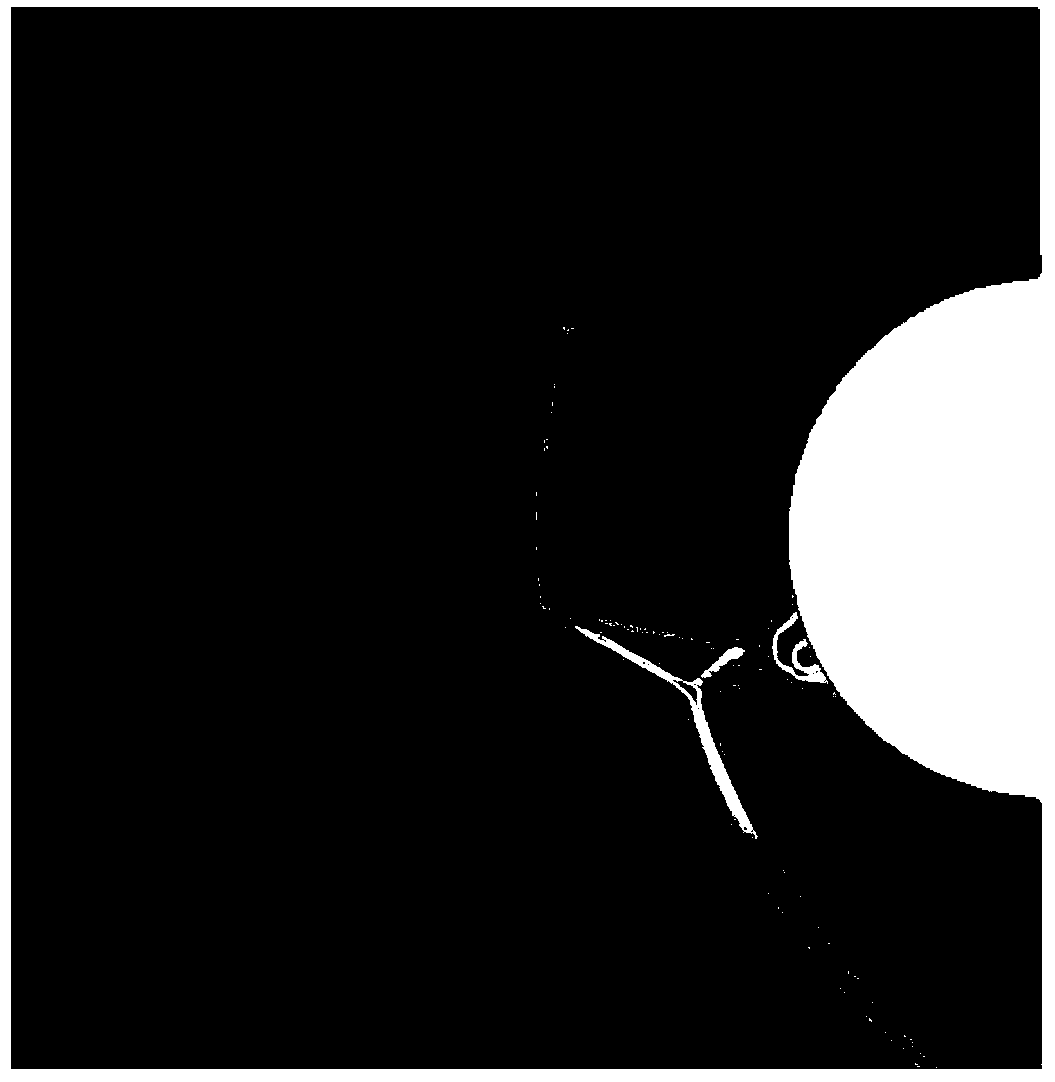

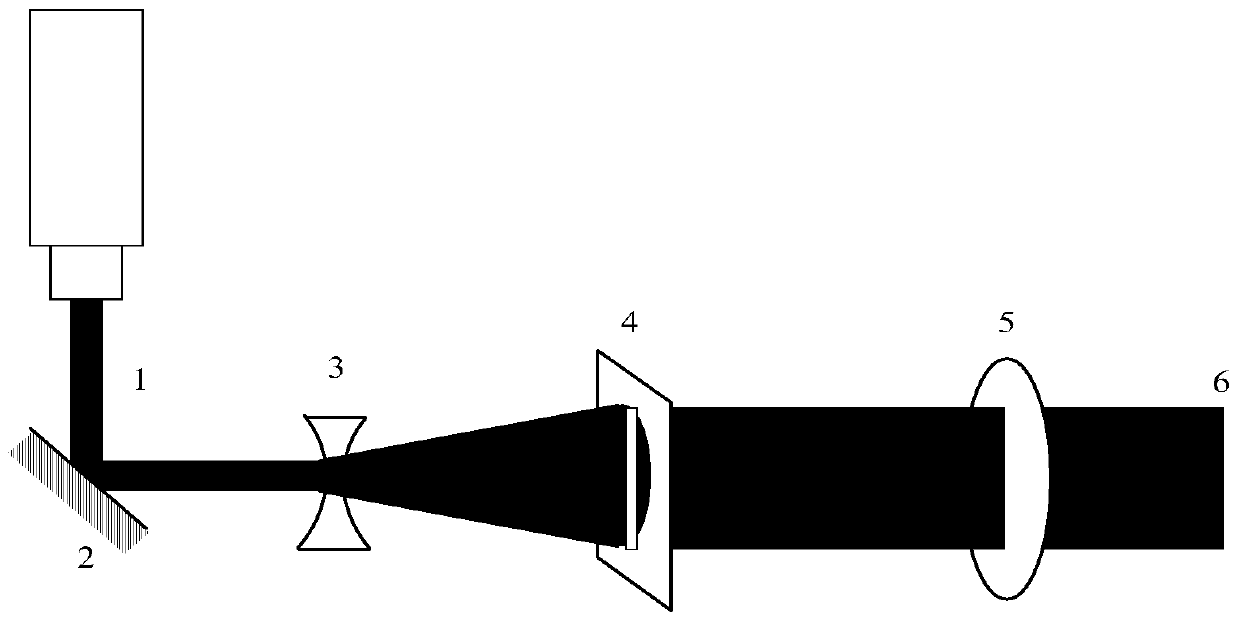

[0031] The method of using laser energy to reduce heat load and wave resistance of Type IV shock wave interference of the present invention will be further described in detail with reference to the accompanying drawings and embodiments. figure 1 The structure diagram of type IV shock wave interference wave system to be controlled by the present invention is given.

[0032] The realization scheme of the present invention is as follows: On the basis of in-depth analysis of the influence of IV-type shock wave interference on the performance of the aircraft, a heat insulation and drag reduction method based on laser energy injection is proposed. The invention is divided into four steps, that is, the step of determining the position and intensity of IV type shock wave interference, the step of shaping the laser beam into sheet light, the step of forming quasi-static wave and the step of reducing drag and heat. The specific implementation plan is as follows:

[0033] Step 1. Estima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com