LED combined matrix light source for surface detection of heavy rail

A technology of surface detection and combination matrix, which is applied in the field of LED combination matrix light source, can solve the problems of uneven distribution of light brightness and difficulty in accurately detecting the surface of heavy rails, etc., and achieve the effect of good light distribution effect, simple structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

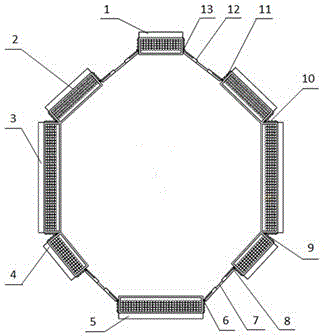

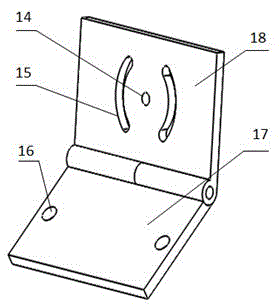

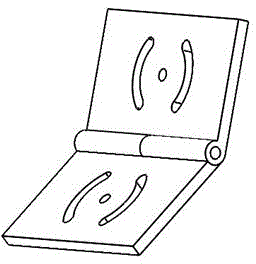

[0038] An LED combination matrix light source for heavy rail surface detection. like figure 1 and Figure 6 As shown, the LED combined matrix light source includes an upper LED matrix light source 1, a lower LED matrix light source 5, two positive side LED matrix light sources 3, two upper side LED matrix light sources 2, two lower side LED matrix light sources 4, two A first telescopic member 7, two second telescopic members 12 and a hinge. The hinges are two first hinges 6, two second hinges 8, two third hinges 9, two fourth hinges 10, two fifth hinges 11 and two sixth hinges Page 13.

[0039] like figure 1 and Figure 6 As shown, the lower LED matrix light source 5 is arranged horizontally, and the upper LED matrix light source 1 is arranged in parallel directly above the lower LED matrix light source 5, and the connecting line between the center of the upper LED matrix light source 1 and the center of the lower LED matrix light source 5 is a lead perpendicular. The...

Embodiment 2

[0051] An LED combination matrix light source for heavy rail surface detection. Except following technical parameter, all the other are with embodiment 1.

[0052] The length of the upper LED matrix light source 1 is 1.07-1.10 times the width of the tread of the heavy rail 25 to be tested.

[0053] The length of the lower LED matrix light source 5 is 1.07-1.10 times the width of the bottom surface of the heavy rail 25 to be tested.

[0054] The length of the positive LED matrix light source 3 is 1.07-1.10 times the height H of the heavy rail 25 to be measured.

[0055] The length of the upper LED matrix light source 2 is 1.07 to 1.10 times the length of the line connecting the neutral axis of the rail waist and the upper end of the rail bottom side of the cross section of the heavy rail 25 to be measured.

[0056] The length of the lower LED matrix light source 4 is 1.07 to 1.10 times the length of the line connecting the neutral axis of the rail waist and the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com