Needle Roller Mounting Structure for Needle Roller Bearings

A technology for needle roller bearings and installation structures, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc. It can solve the problems of unsmooth rotation of needle rollers, poor stability, and easy wear and tear of needle rollers, and achieve simple structure and Good lubrication and good installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

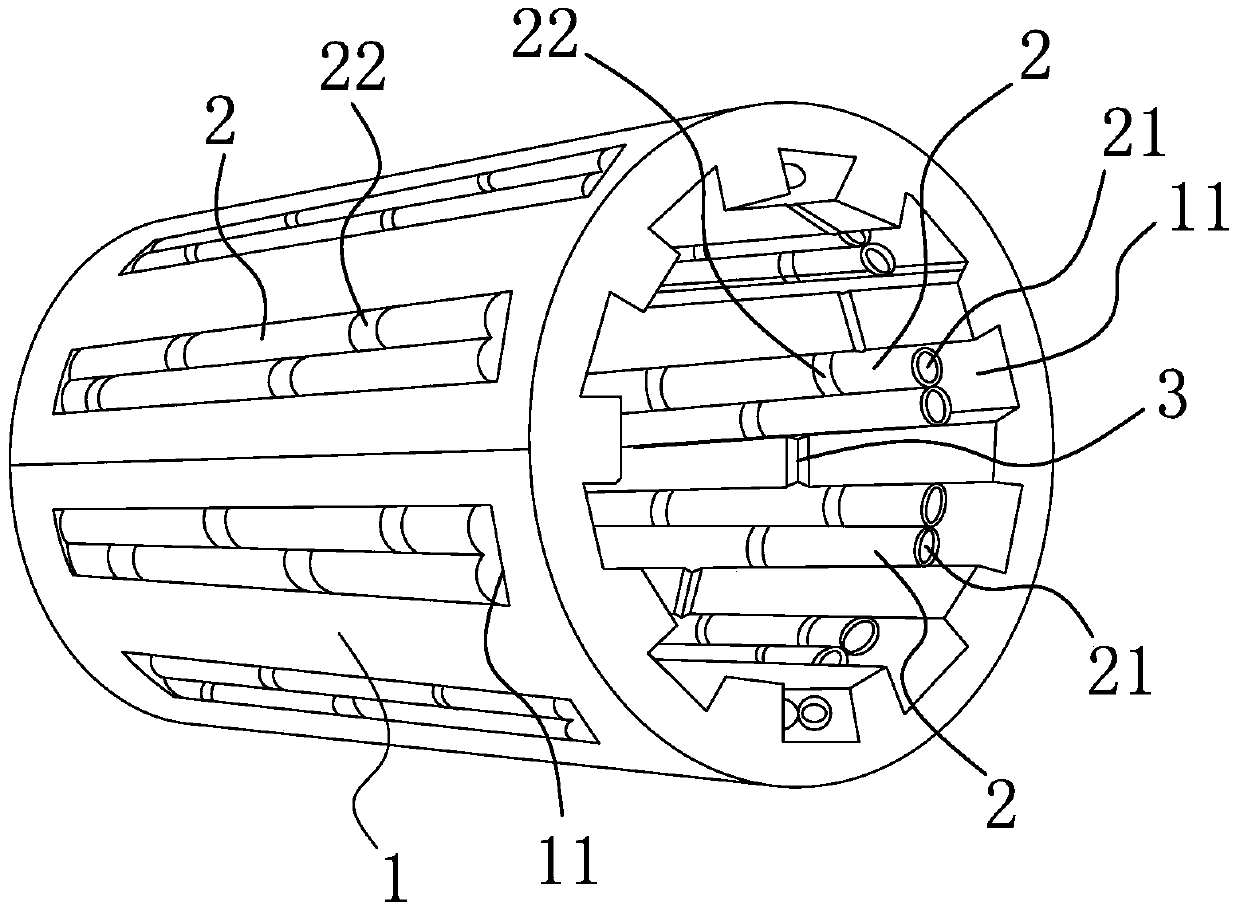

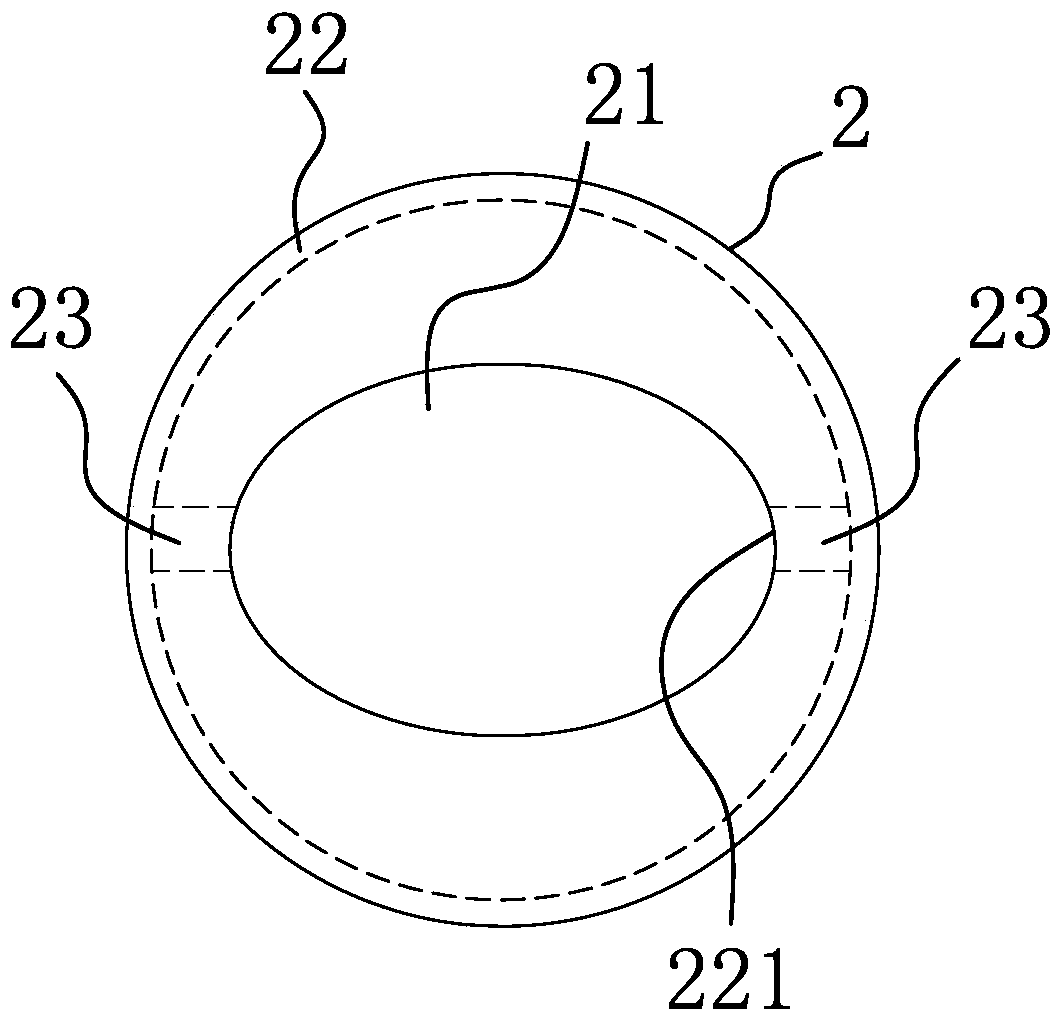

[0023] Such as Figure 1-2 As shown, the needle roller installation structure of the needle roller bearing includes a cylindrical needle roller cage body 1, and a plurality of retaining grooves 11 extending axially along the needle roller cage body 1 are provided in the circumferential direction of the needle roller cage body 1. Each holding groove 11 is provided with at least two needle rollers 2 side by side in sequence. The needle rollers 2 are axially arranged in the holding groove 11 and two adjacent needle rollers 2 are arranged against each other. The needle rollers 2 are Cylindrical, in the needle roller body 2 there is a non-circular through hole 21 extending axially along the needle roller body 2 and having a cross-section with at least two protrusions. Annular grooves 22, the annular grooves 22 are distributed sequentially along the axial direction of the needle roller body 2 and the annular grooves 22 on two adjacent needle roller bodies 2 are alternately arranged ...

Embodiment 2

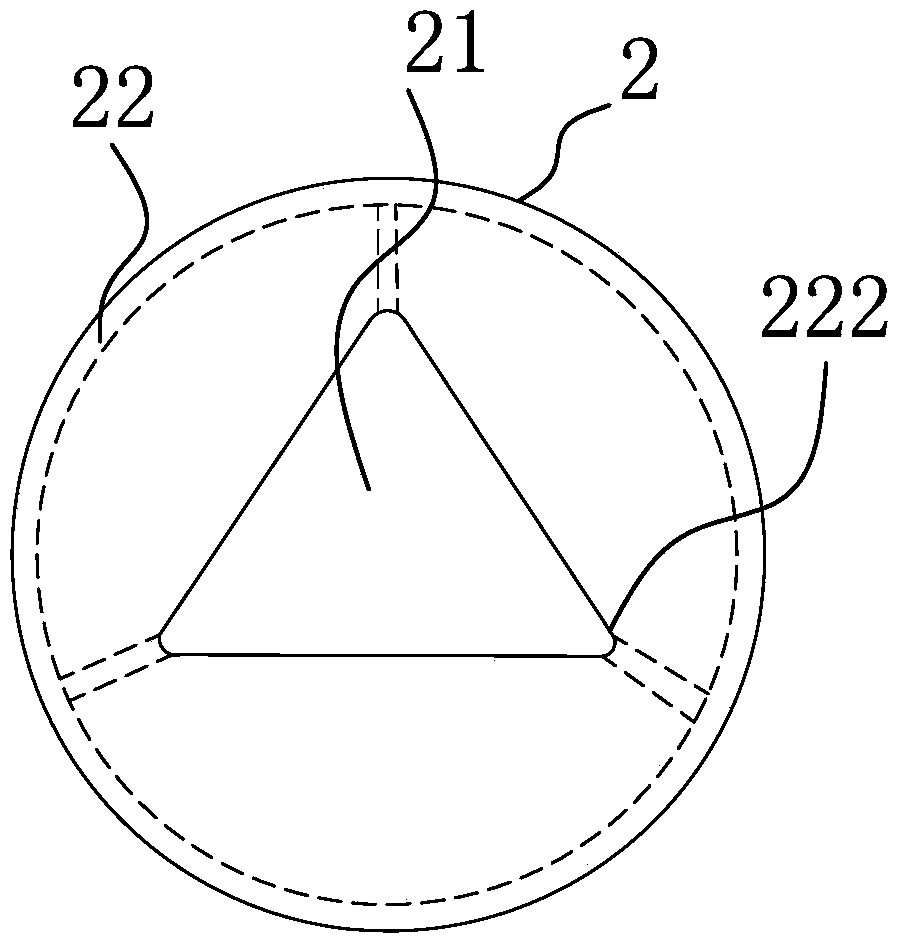

[0029] Such as image 3 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that the cross section of the through hole 21 in this embodiment is a polygon with at least three corners 222. The corner 222 forms the above-mentioned protrusion, and the number of oil holes 23 on each annular groove 22 is at least three, and the oil holes 23 are respectively arranged on the side of the annular groove 22 that is close to the corner 222 in the circumferential direction, That is, there are at least three oil holes 23 on the annular groove 22 here, and they are respectively arranged on each corner of the polygonal through hole 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com