A downhole real-time sand mixer

A sand mixer and center hole technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of long sand concentration control process, inability to carry out real-time control, etc., to expand volume and increase pressure. The effect of fracturing stimulation and fracturing construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

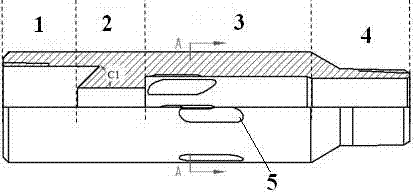

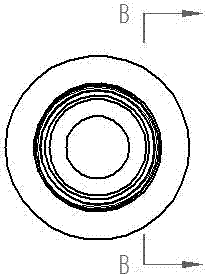

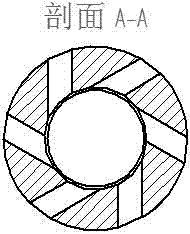

[0024] This embodiment provides a figure 1 , figure 2 , image 3 , Figure 4 The downhole real-time sand mixer shown is a cylinder, and the center hole of the cylinder is the center hole 1 of the first section, the center hole 2 of the second section, and the center hole 3 of the third section from top to bottom. , the center hole 4 of the fourth section, the center hole 1 of the first section, the center hole 2 of the second section, the center hole 3 of the third section, and the center hole 4 of the fourth section are all cylindrical through holes;

[0025] The inner diameter of the central hole 1 of the first section is greater than the inner diameter of the central hole 3 of the third section, the inner diameter of the central hole 3 of the third section is greater than the inner diameter of the central hole 4 of the fourth section, and the inner diameter of the central hole 4 of the fourth section is greater than the inner diameter of the central hole 2 of the second ...

Embodiment 2

[0031] On the basis of Example 1, this embodiment provides a downhole real-time sand mixer. The downhole real-time sand mixer is a cylinder with internal threads on the upper end and external threads on the lower end. The outer diameter of the cylinder is 95 mm. The central hole in the sand mixer is divided into four sections from top to bottom. The inner diameter of the central hole 1 of the first section is the largest, which is 62mm, and the inner diameter of the central hole 2 of the second section is the smallest, which is 31mm. The central hole 1 of the first section and the second section The transition surface of the center hole 2 is a conical table surface that is raised upwards. The upper part of the truncated cone is smaller and the lower part is larger. The inner diameter is consistent, 31mm, the angle C1 between the conical surface of the truncated cone and the central axis of the inner hole is 45°; the inner diameter of the third central hole 3 is 47mm, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com