A Multifunctional Hydraulic Buffer Hinge

A hydraulic buffering and multi-functional technology, applied in the hinge field, can solve the problems of door and door frame impact, long working time, loss of buffer closing, etc., and achieve the effects of good sealing performance, long service life and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

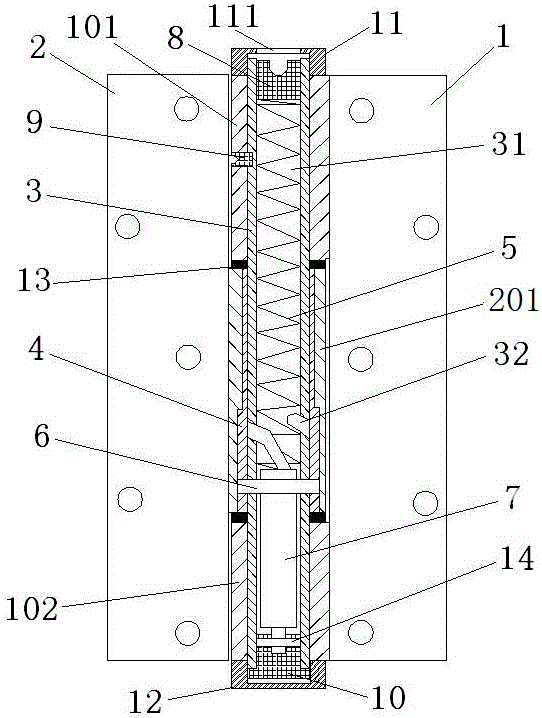

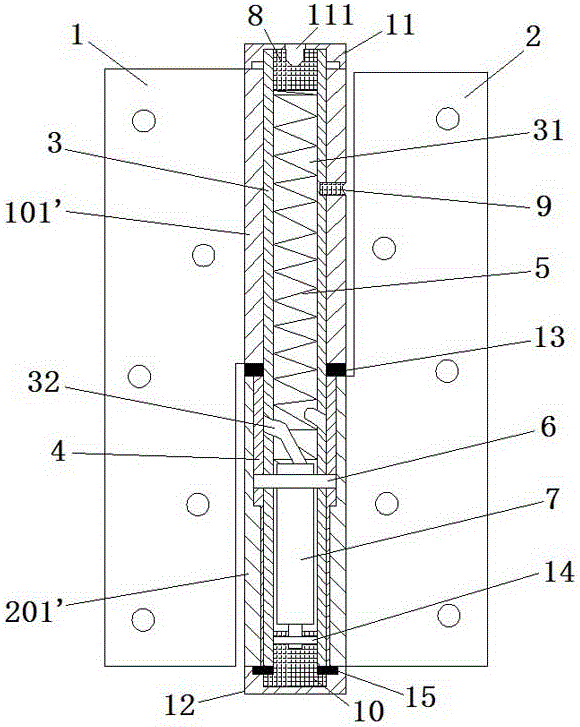

[0026] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] see in conjunction Figure 1 to Figure 7 As shown, an embodiment of the present invention is a multifunctional hydraulic buffer hinge, which includes a first leaf 1, a second leaf 2 and a shaft core mechanism; the first leaf 1 passes through the shaft core mechanism Rotately connected with the second sheet 2; the shaft core mechanism includes a screw rod 3, a protective sleeve 4, a spring 5, a needle roller 6 and a hydraulic cylinder 7; the screw rod 3 is set in the protective sleeve 4, The screw rod 3 is fixedly connected to the first sheet 1, and the protective cover 4 is fixedly connected to the second sheet 2; the screw rod 3 has a hollow cavity 31, the spring 5 and the hydraulic cylinder 7 are all arranged in the hollow cavity 31, one end of the spring 5 is provided with an adjustment screw 8 for adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com