Sludge dewatering flocculant and its dewatering method

A sludge dehydration and flocculant technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of unsatisfactory effect, achieve the effect of improving dehydration effect, reducing toxic and harmful substances, and enhancing flocculation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

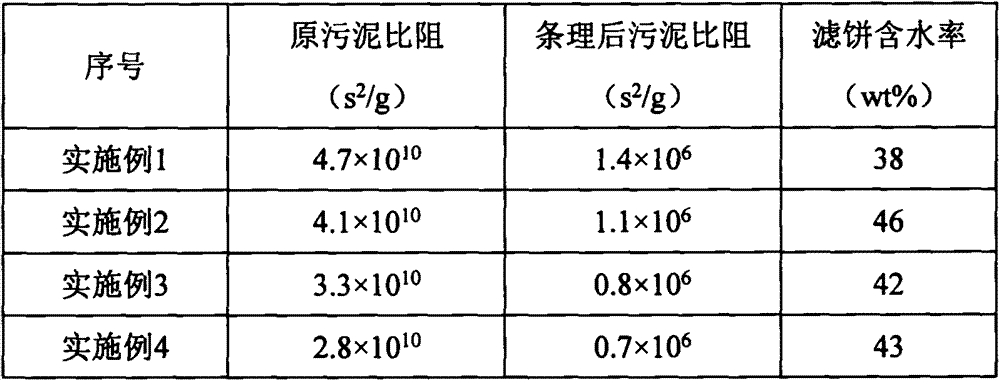

Examples

Embodiment 1

[0017] The sludge dewatering flocculant is composed of agent A and agent B; the agent A is made of the following raw materials in parts by weight: 28 parts of ferrous sulfate, 10 parts of heavy metal scavenger, 43 parts of blue carbon, 12 parts of lime powder, 12 parts of alkylamine polyoxyethylene ether phosphate, 9 parts of lignosulfonate;

[0018] The agent B is prepared from the following raw materials in parts by weight: 35 parts of betaine, 20 parts of tetraethylenepentamine, 9 parts of formaldehyde, 9 parts of ethanol and 55 parts of water.

[0019] The preparation method of the A agent comprises: grinding ferrous sulfate, semi-coke, and lime powder through a 500-mesh sieve, and then mixing and stirring evenly with the heavy metal scavenger, alkylamine polyoxyethylene ether phosphate, and lignosulfonate.

[0020] The preparation method of the B agent includes adding tetraethylenepentamine and ethanol into the reaction kettle and stirring until the tetraethylenepentamine...

Embodiment 2

[0026] The sludge dewatering flocculant is composed of agent A and agent B; the agent A is made of the following raw materials in parts by weight: 20 parts of ferrous sulfate, 6 parts of heavy metal scavenger, 42 parts of blue carbon, 15 parts of lime powder, 14 parts of alkylamine polyoxyethylene ether phosphate, 6 parts of lignosulfonate;

[0027] The B agent is made of the following raw materials in parts by weight: 37 parts of betaine, 15 parts of tetraethylenepentamine, 8 parts of formaldehyde, 15 parts of ethanol, and 45 parts of water.

[0028] The preparation method of the A agent comprises: grinding ferrous sulfate, semi-coke, and lime powder through a 500-mesh sieve, and then mixing and stirring evenly with the heavy metal scavenger, alkylamine polyoxyethylene ether phosphate, and lignosulfonate.

[0029] The preparation method of the B agent includes adding tetraethylenepentamine and ethanol into the reaction kettle and stirring until the tetraethylenepentamine is d...

Embodiment 3

[0035] The sludge dewatering flocculant is composed of agent A and agent B; the agent A is made of the following raw materials in parts by weight: 25 parts of ferrous sulfate, 8 parts of heavy metal scavenger, 45 parts of blue carbon, 17 parts of lime powder, 10 parts of alkylamine polyoxyethylene ether phosphate, 4 parts of lignosulfonate;

[0036] The B agent is made of the following raw materials in parts by weight: 40 parts of betaine, 23 parts of tetraethylenepentamine, 10 parts of formaldehyde, 10 parts of ethanol, and 50 parts of water.

[0037] The preparation method of the A agent comprises: grinding ferrous sulfate, semi-coke, and lime powder through a 500-mesh sieve, and then mixing and stirring evenly with the heavy metal scavenger, alkylamine polyoxyethylene ether phosphate, and lignosulfonate.

[0038] The preparation method of the B agent includes adding tetraethylenepentamine and ethanol into the reaction kettle and stirring until the tetraethylenepentamine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com