Preparation method for activated carbon with medium pore radii

A technology of activated carbon and coconut shell activated carbon is applied in the field of preparation of pore-sized activated carbon, which can solve the problems of high production cost and complicated process, and achieve the effect of mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

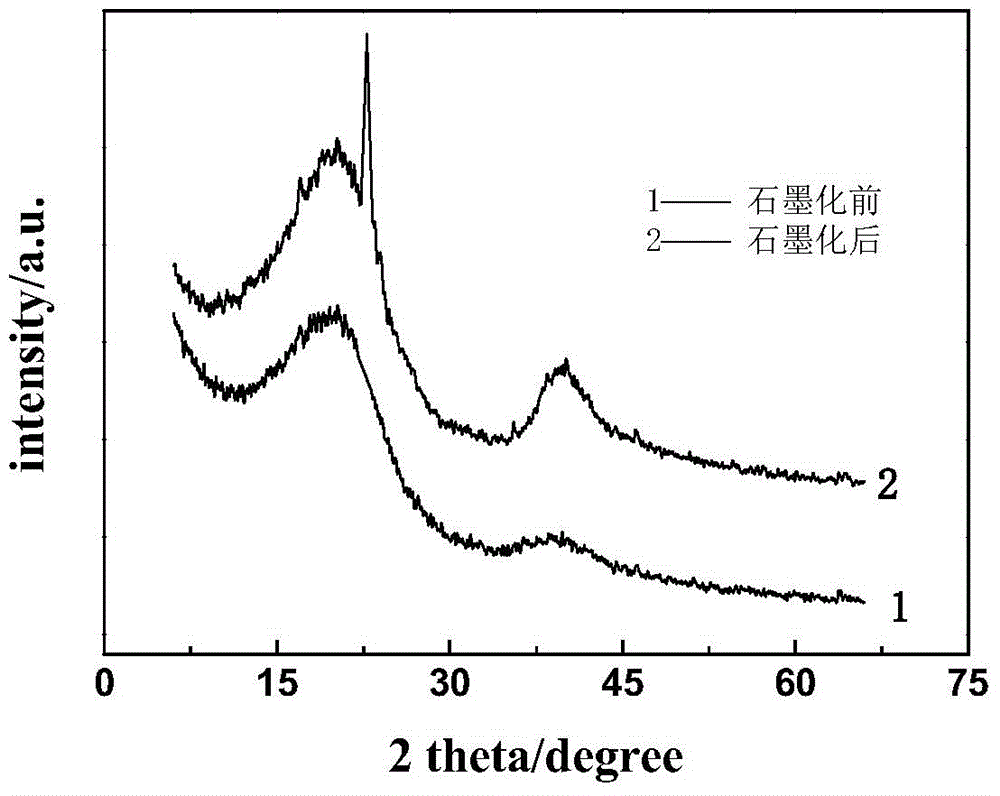

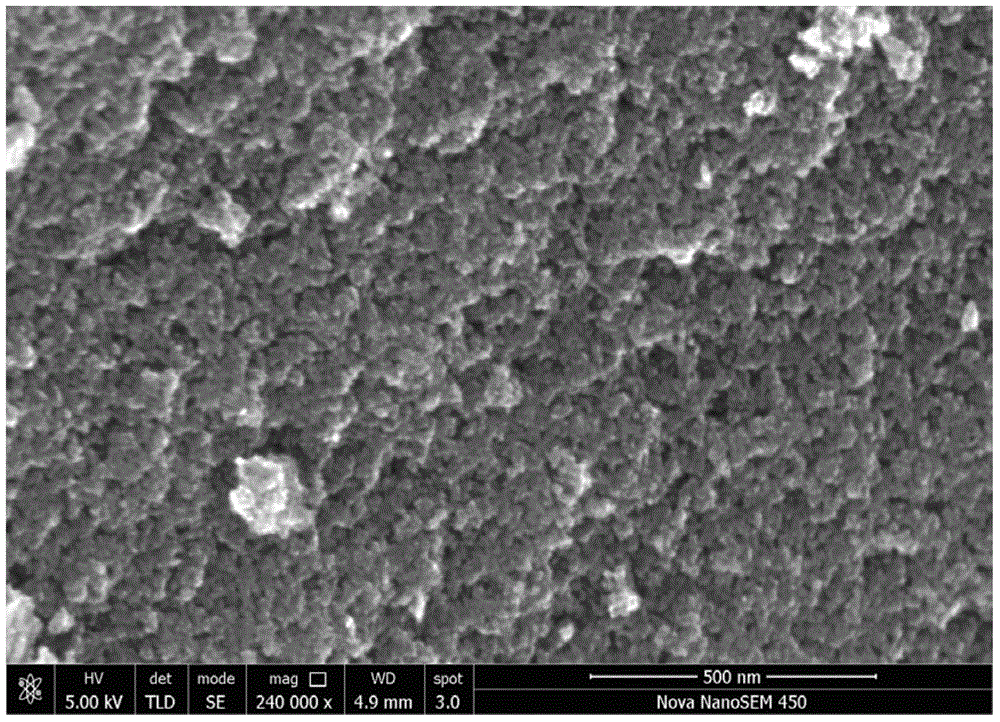

[0036] 500g wood activated carbon, 325 mesh, specific surface area 1850~1910m 2 / g, soak in 1.5L of 35% ethanol aqueous solution, the concentration of potassium hydroxide is 1mol / L, after stirring for 10 minutes, transfer it to an ultrasonic cleaner, adjust the ultrasonic frequency to 50Hz, and the ultrasonic power to 1W / cm 2 , after 1 hour, filter with suction, wash with 2L of water, wash 5 times in total, blow dry at 100°C for 2 hours, then transfer to a tubular muffle furnace, first vacuumize, then continuously feed nitrogen, and then rapidly heat up to 1700°C , After 1.5h of heat preservation, the mesoporous activated carbon with high conductivity can be obtained by natural cooling.

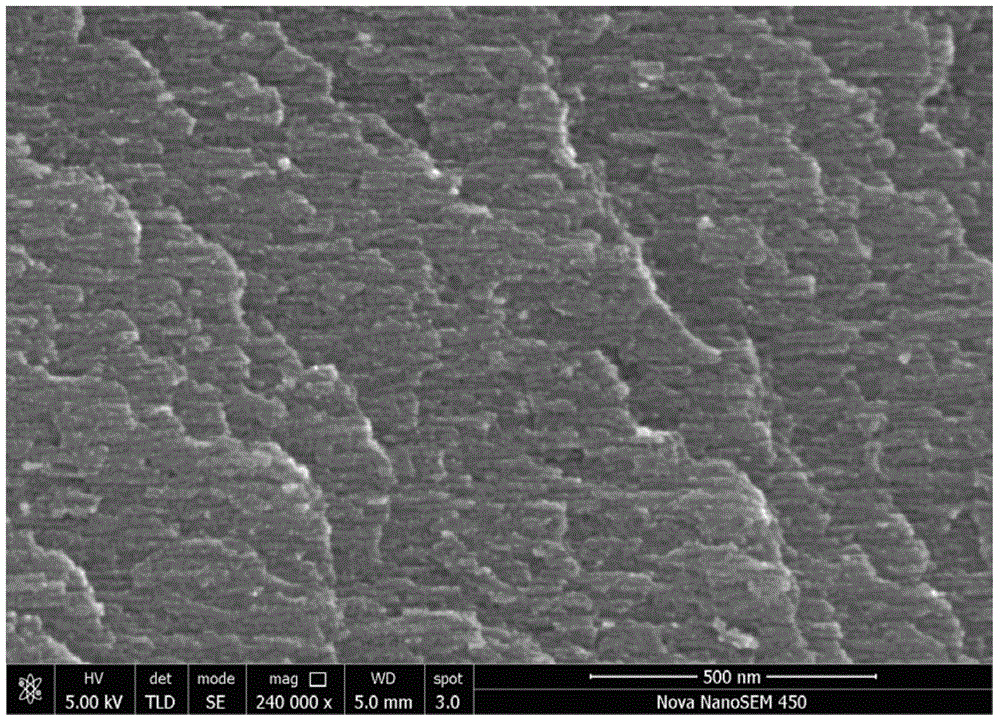

[0037] The particle size of activated carbon is 300-400 mesh, accounting for 92.7% of the total, 1.4% for 300 mesh or more, and 5.9% for 400 mesh or less (GB / T 12496.2-1999 Test method for wood activated carbon-determination of particle size distribution); the specific surface area is 2733m ...

Embodiment 2

[0039] 500g wood activated carbon, 120 mesh, specific surface area 1530m 2 / g, soak in 1.5L of 45% ethanol aqueous solution, the concentration of potassium hydroxide is 1.5mol / L, after stirring for 10 minutes, transfer to an ultrasonic cleaner, ultrasonic frequency 50Hz, ultrasonic power 1.5W / cm 2 , after 2 hours of ultrasonic time, filter with suction, wash with 2L water each time until neutral, and dry at 100°C for 2 hours, then transfer to a tubular muffle furnace, first vacuum, then nitrogen, and then quickly heat up To 2000°C, keep warm for 1.5h, then cool naturally.

[0040]The particle size of activated carbon is 100-150 mesh, accounting for 94.8% of the total, 0.8% above 100 mesh, and 4.4% below 400 mesh (GB / T 12496.2-1999 Determination of particle size distribution of wood activated carbon test method); the specific surface area is 2530m 2 / g, resistivity 1.73×10 -3 Ωm (four-probe resistivity measuring instrument), specific pore volume 2.17ml / g, average pore diamete...

Embodiment 3

[0042] 500g coal-based activated carbon, 100 mesh, specific surface area 1360m 2 / g, soak in 1.5L of 25% ethanol aqueous solution, the concentration of potassium hydroxide is 1mol / L, after stirring for 10 minutes, transfer it to an ultrasonic cleaner, the ultrasonic frequency is 50Hz, and the ultrasonic power is 1.5W / cm 2 , after 2 hours of ultrasonic time, filter with suction, wash with 2L water each time until neutral, and dry at 100°C for 2 hours, then transfer to a tubular muffle furnace, first vacuum, then nitrogen, and then quickly heat up To 2000°C, keep warm for 1.5h, then cool naturally.

[0043] The particle size of activated carbon is 80-120 mesh, accounting for 95.1% of the total, 1.9% above 100 mesh, and 4.4% below 120 mesh (GB / T 12496.2-1999 Test method for wood activated carbon-determination of particle size distribution); the specific surface area is 2530m 2 / g, resistivity 0.28×10 -3 Ωm (four-probe resistivity measuring instrument), specific pore volume 1.33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com