Adaptive Pressure Balance Control System Based on Microcontroller

A micro-controller and balance control technology, which is applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problem of poor stability and accuracy of balance crane work, large range of pressure regulator valves, and difficulty in matching adjustment parameters and other issues, to achieve light weight, improve production efficiency, and reduce the number of stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

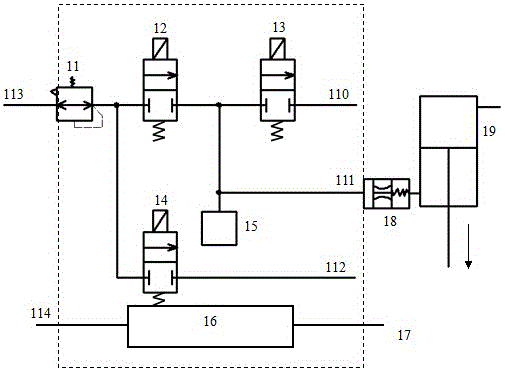

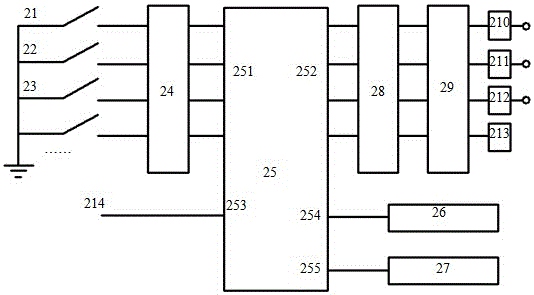

[0021] Such as figure 1 , figure 2 , the self-adaptive pressure balance control system based on the micro-controller of the present invention is mainly used in the balance crane to control the movement of the balance crane cylinder, mainly composed of the air inlet 113, the exhaust port 110, the air control safety valve 18 and the cylinder 19 , composed of a pneumatic transmission circuit and a control circuit; wherein the pneumatic transmission circuit includes a pressure regulating valve 11, an intake solenoid valve 12, an exhaust solenoid valve 13 and a pressure sensor 15, and one end of the intake solenoid valve 12 passes through the pressure regulating valve 11 and the air inlet 113, the other end is connected to the exhaust solenoid valve 13, the other end of the exhaust solenoid valve 13 is connected to the exhaust port 110, the pressure sensor 15 is connected between the intake solenoid valve 12 and the exhaust solenoid valve 13, and Link to each other with cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com