In-mold detachable stamping device

A marking device, technology in the mold, applied in the field of marking devices, can solve the problems of time-consuming, low maintenance work efficiency, troublesome disassembly work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

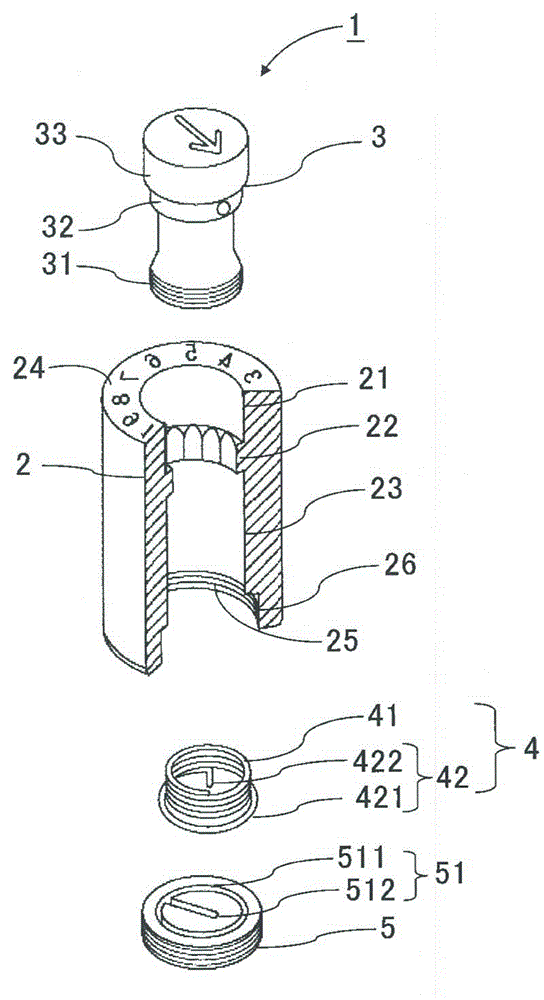

[0036] Hereinafter, embodiments of the in-mold detachable marking device of the present invention will be explained with reference to the accompanying drawings. figure 1 is an exploded perspective view showing the in-mold detachable marking device of the present invention.

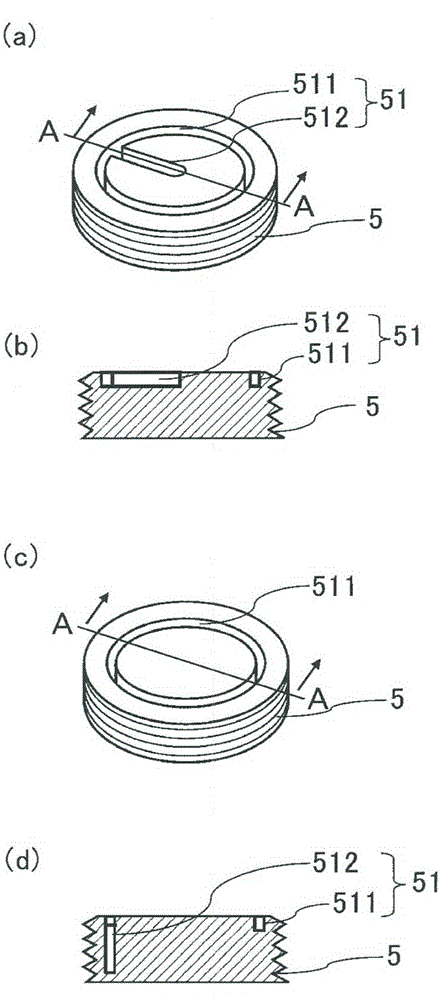

[0037] The in-mould detachable marking device 1 of the present invention (hereinafter referred to as marking device 1 ) comprises a substantially cylindrical outer housing 2 for indication, fitted to the above-mentioned outer housing 2 for indication and configured to surround the The indicating body 3 with the axis of the indicating outer housing angularly moving, the cover 5 screwed to the bottommost 26 of the indicating outer housing 2 , and the spring 4 biasing the indicating body 3 with a downward force.

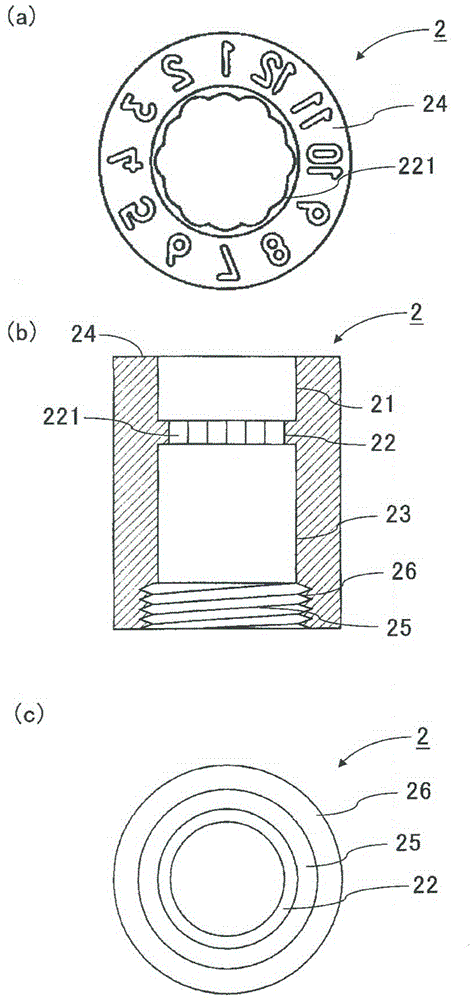

[0038] The inner wall surface 2 of the outer housing for indication is divided into three regions; the upper section 21 receives the marking section 3, the middle section 22 is located below the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com