Alkane catalytic conversion method and reactor thereof

A catalytic conversion method and a catalytic conversion technology, which are applied in the field of alkane catalytic conversion methods and reaction equipment, can solve the problem of low alkane conversion rate and product selectivity, improve yield and selectivity, maintain continuous and efficient progress, and increase The effect of high contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

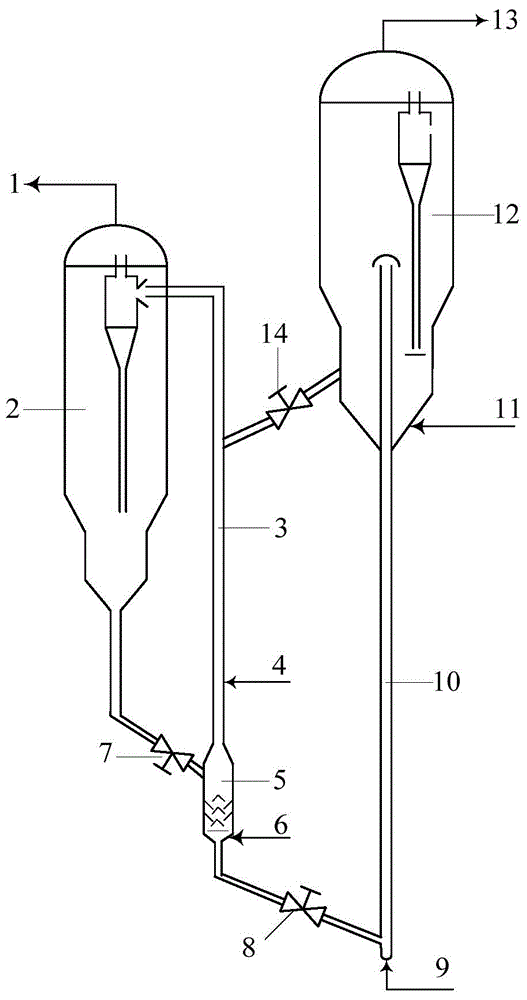

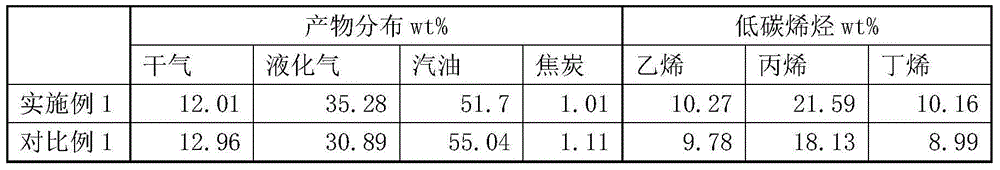

[0037] Using ZSM-5 molecular sieve as the catalyst with an average particle size of 80 μm, and light naphtha (gasoline fraction with a boiling range of 20°C to 70°C) as the raw material of alkanes, such as figure 1 Catalytic conversion reaction is carried out in the alkane catalytic conversion reaction equipment shown. The fluidized bed reactor has an inner diameter of 50mm and a height of 3000mm. Superheated steam at 500°C is used as the stripping medium and air is used as the regeneration medium. The regeneration of the catalyst The temperature is controlled at 700°C, and the mixing temperature of the oil agent in the fluidized bed reactor is controlled at about 600°C after the oil gas and the catalyst contact. The linear velocity of mixed oil and gas is controlled at 0.8m / s, and the residence time of mixed oil and gas is controlled at 3s.

Embodiment 2

[0044] Methane catalytic cracking hydrogen production catalyst with nickel as the active component and alumina as the carrier, the average particle size is 100 μm, methane is the raw material of alkanes, in such as figure 1 Catalytic conversion reaction is carried out in the alkane catalytic conversion reaction equipment shown. The inner diameter of the fluidized bed reactor is 50mm, the height is 3000mm, the superheated steam at 500°C is used as the stripping medium, and air is used as the regeneration medium. The regeneration temperature of the catalyst is Control the temperature at 780°C, the oil mixture temperature after the contact between oil gas and catalyst in the fluidized bed reactor is controlled at about 700°C, the speed of the regenerated catalyst into the fluidized bed reactor is 30 kg / hour, the mixing of the fluidized bed reactor The linear velocity of oil and gas is controlled at 1.5m / s, and the residence time of mixed oil and gas is controlled at 10s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com