Overhead conveying rail change system

A technology for carrying rails and trolleys, used in conveyors, mechanical conveyors, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

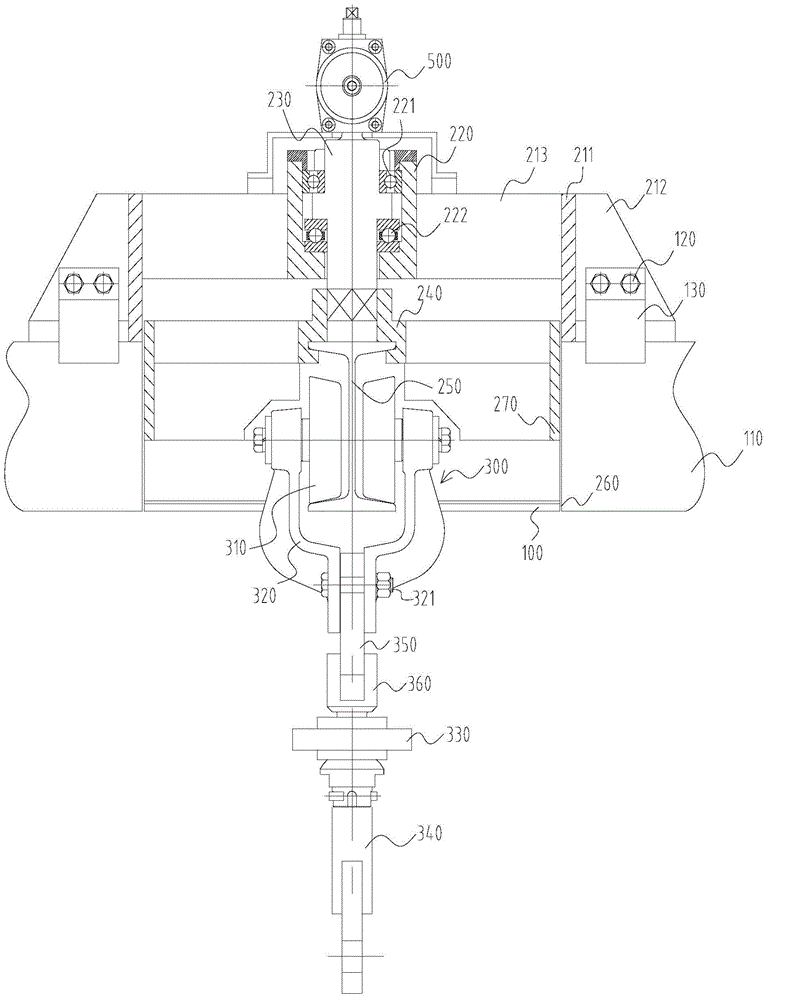

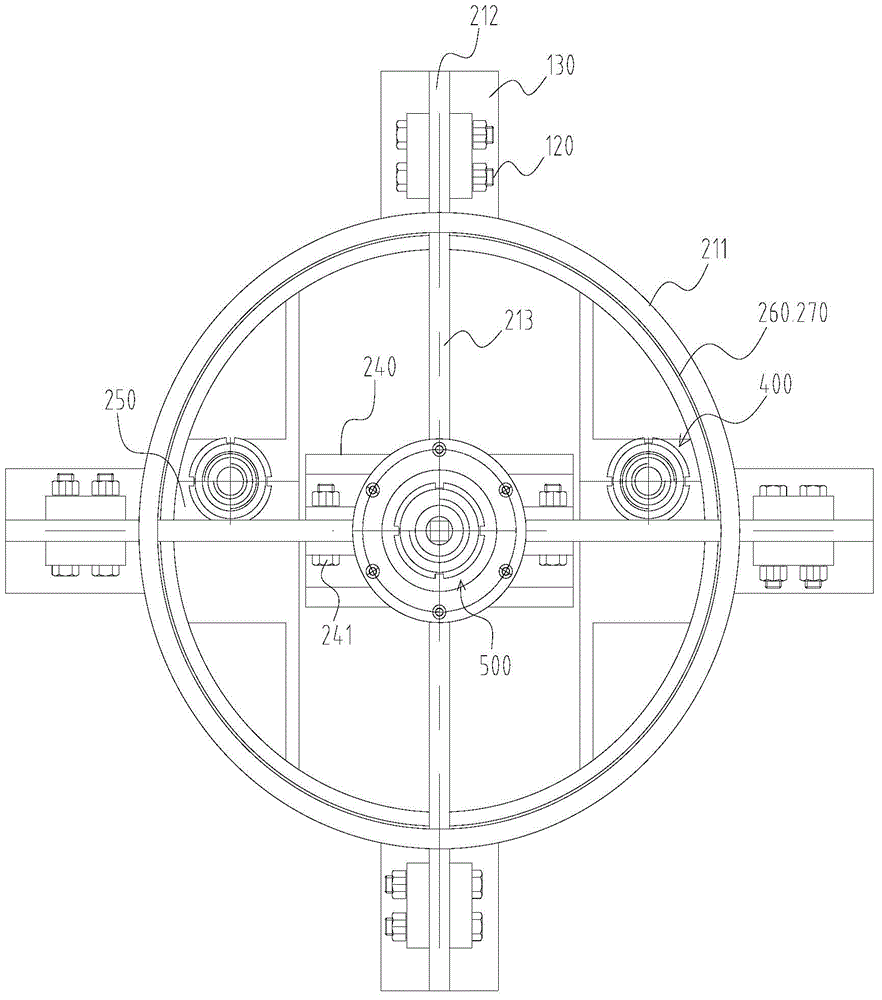

[0029] see Figure 1 to Figure 5 , the suspension conveying rail changing system given in the figure includes four fixed bearing rails 110 distributed at 90 degrees on a horizontal plane, and the ends of the four fixed bearing rails 110 are not connected to define a rail changing area 100 . Of course, the number of fixed bearing rails 110 is not limited to four, and may also be three or more.

[0030] The support plate 210 in the entire suspension conveying rail change system comprises a support plate cylinder 211, four support ears 212 are evenly distributed on the outer peripheral surface of the support plate cylinder 211, and the four support ears 212 are respectively fixed on four Four pairs of support lugs 130 and fastening bolts 120 on the fixed bearing rails 110 are fixed on the four fixed bearing rails 110 .

[0031] The bearing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com