A roll assembly

A roll and bearing technology, applied in the field of metal pipe or wire and bar rolling equipment, can solve the problems of increased rolling force and rolling torque, reduced steel pipe yield, and increased stand spacing, etc., to achieve shortened length and reduced Maintenance cost, effect of increase in finish rolling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

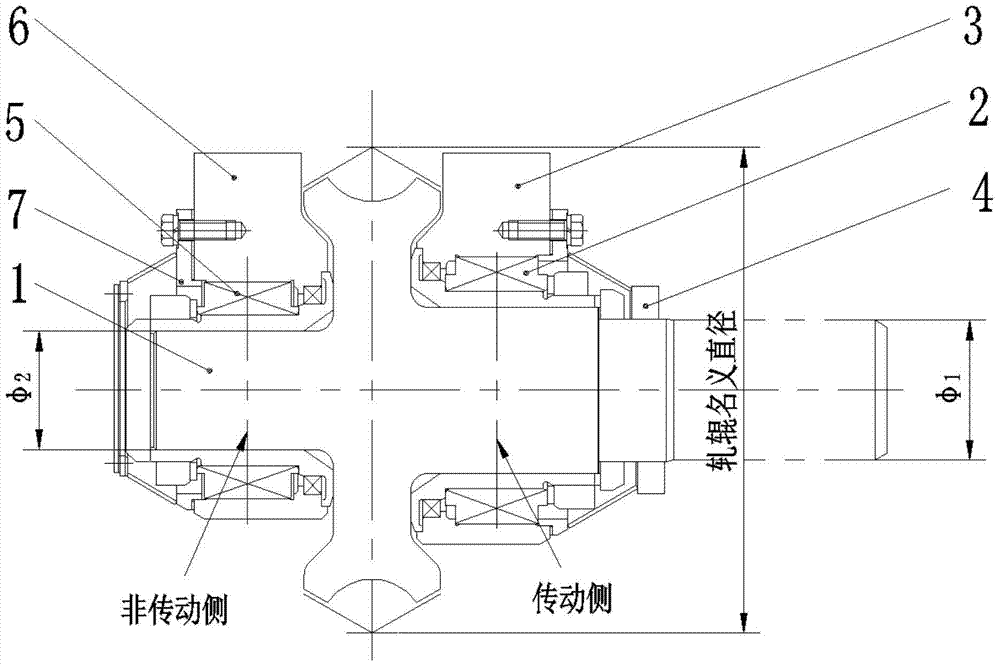

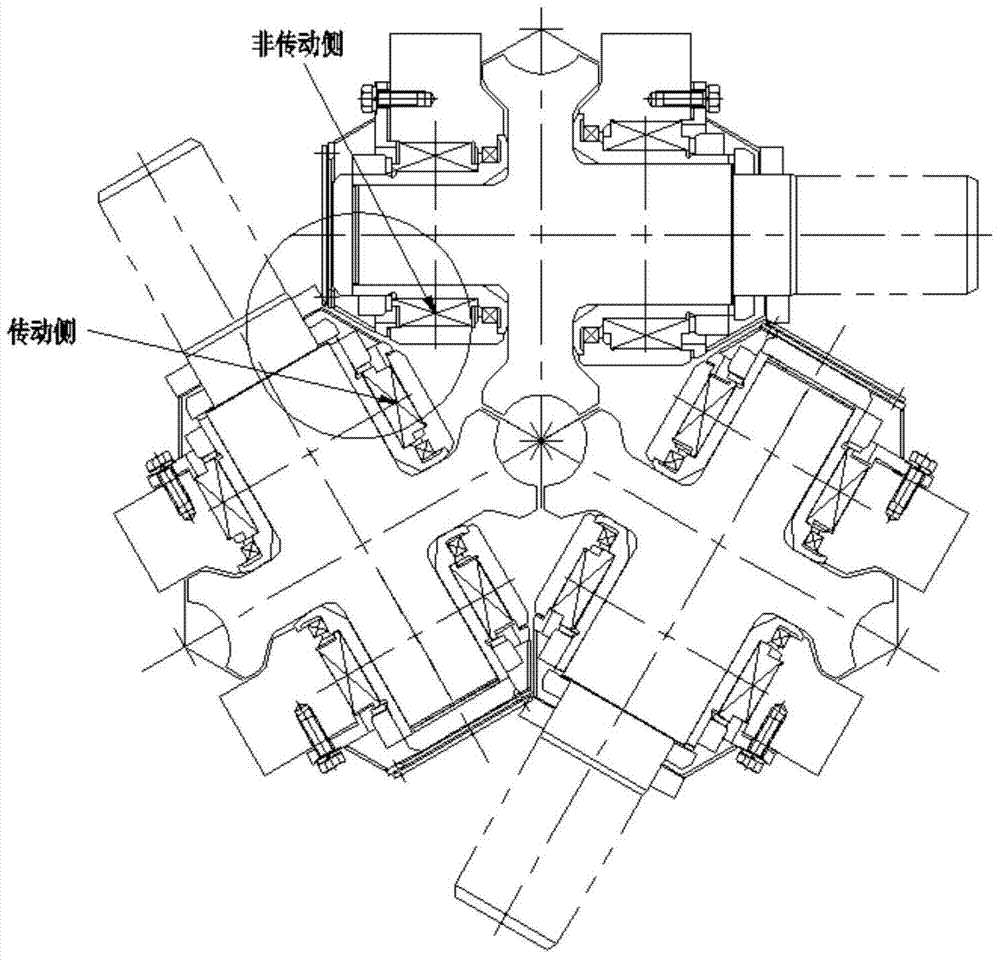

[0012] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0013] Such as figure 1 As shown, the roll assembly in the present invention includes roll 1, bearing I2, bearing housing I3, bearing cover I4 arranged on the transmission side of roll 1, and bearing II5, bearing housing II6 and bearing cover correspondingly arranged on the non-driving side of roll 1 Ⅱ7, the outer diameter of the journal on the non-drive side of the roll Smaller than the outside diameter of the journal on the drive side The main dimensions of the bearing II5 are smaller than the main dimensions of the bearing I2, and the outer dimensions of the bearing seat II are smaller than the outer dimensions of the bearing seat I.

[0014] In this embodiment, the bearing I2 is set on the journal of the transmission side of the roll 1, and the bearing seat I3 and the bearing cover I4 are installed on the outside of the bearing I2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com