Hypoallergenic whey protein powder based on enzyme-method galactosylated modification and preparation method thereof

A technology of whey protein powder and whey protein, applied in protein food processing, protein food ingredients, food science, etc., can solve problems such as bad color and flavor, and damage to protein structure and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

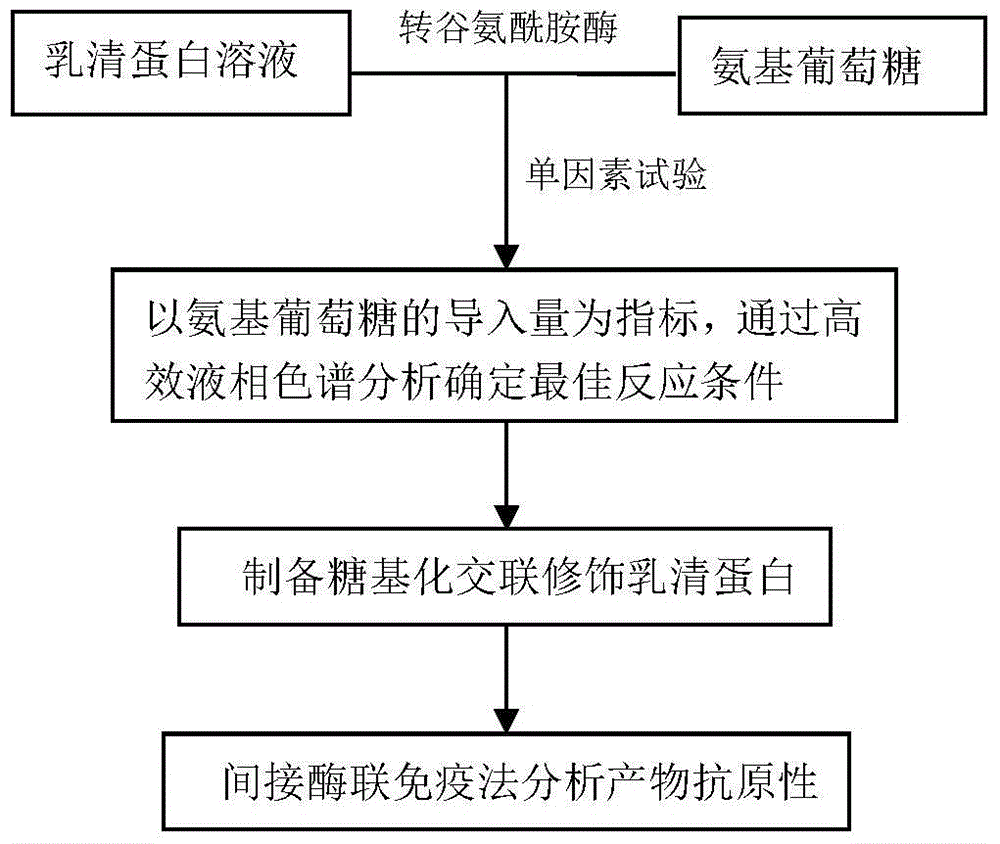

Method used

Image

Examples

preparation example Construction

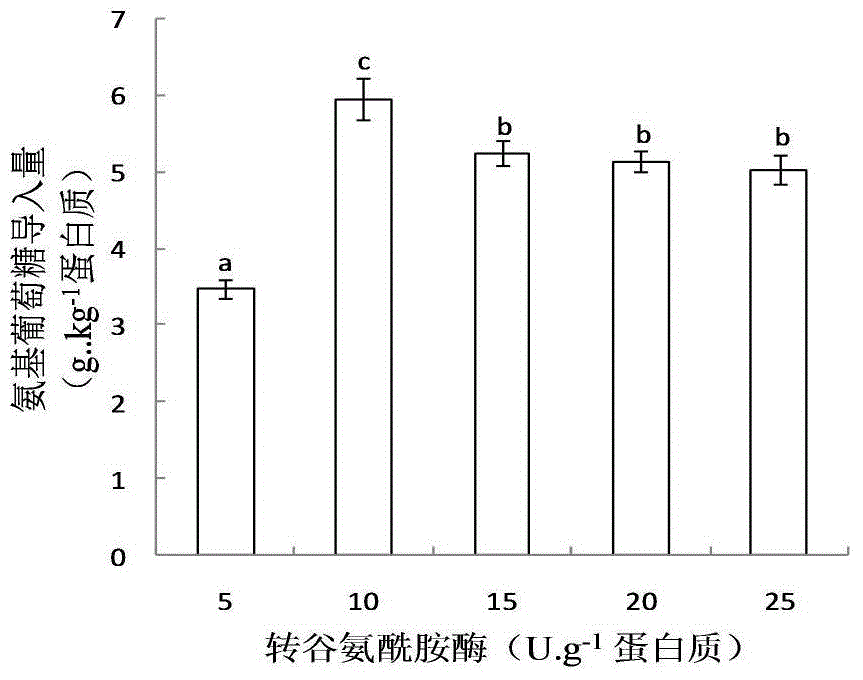

[0015] A hypoallergenic whey protein powder based on enzymatic glycosylation modification and a preparation method thereof, the method comprising the following steps: (1) dissolving whey protein, and the concentration of whey protein in the reaction system is 30-70g·L -1 , mixed with glucosamine hydrochloride solution, the amount of transglutaminase added is 5~25U·g -1 Whey protein, pH 6.2-8.0, 37°C constant temperature water bath shaking reaction for 2-6 hours, after the reaction, take out the sample, put it in an 85°C water bath to inactivate the enzyme for 5 minutes, cool down, adjust the pH value of the solution to 5.0, add an equal volume centrifuge at 8000×g for 10 min, collect the precipitate, wash twice with ethanol, dissolve the precipitate and adjust the pH to 7.0, freeze-dry for later use; (2) Glycosylate and crosslink the whey protein obtained in step (1) After the modified product was hydrolyzed with hydrochloric acid, the amount of glucosamine released in the hyd...

Embodiment 1

[0019] (1) Preparation of glycosylation modified products of whey protein: dissolving whey protein, the concentration of whey protein in the reaction system is 30g L -1 , mixed with glucosamine hydrochloride solution, the amount of transglutaminase added is 10U·g -1 Whey protein, pH 7.5, 37°C constant temperature water bath shaking reaction for 4 hours, after the reaction, take out the sample, put it in an 85°C water bath to inactivate the enzyme for 5 minutes, cool down, adjust the pH value of the solution to 5.0, add an equal volume of absolute ethanol , centrifuged at 8000×g for 10 min, collected the precipitate, washed twice with ethanol, dissolved the precipitate and adjusted the pH to 7.0, and freeze-dried for later use.

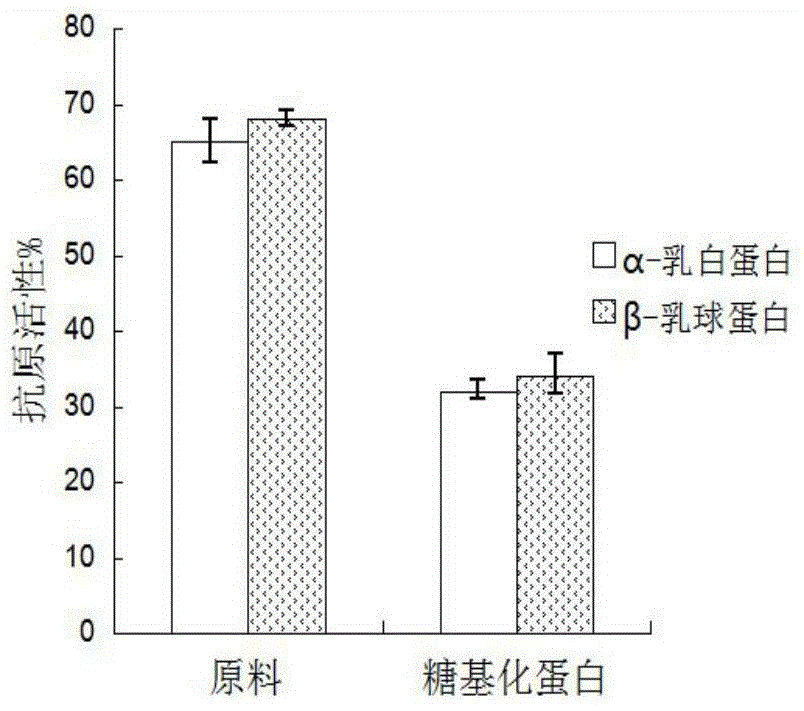

[0020] (2) After the whey protein glycosylation and crosslinking modification product obtained in step (1) is hydrolyzed with hydrochloric acid, the amount of glucosamine released in the hydrolyzate of the whey protein glycosylation modification produc...

Embodiment 2

[0023] (1) Preparation of glycosylation modified products of whey protein: dissolving whey protein, the concentration of whey protein in the reaction system is 50g L -1 , mixed with glucosamine hydrochloride solution, the amount of transglutaminase added is 15U·g -1 Whey protein, pH 7.5, 37°C constant temperature water bath shaking reaction for 4 hours, after the reaction, take out the sample, put it in an 85°C water bath to inactivate the enzyme for 5 minutes, cool down, adjust the pH value of the solution to 5.0, add an equal volume of absolute ethanol , centrifuged at 8000×g for 10 min, collected the precipitate, washed twice with ethanol, dissolved the precipitate and adjusted the pH to 7.0, and freeze-dried for later use.

[0024] (2) After the whey protein glycosylation and crosslinking modification product obtained in step (1) is hydrolyzed with hydrochloric acid, the amount of glucosamine released in the hydrolyzate of the whey protein glycosylation modification produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com