Flux-gate type non-contact current measuring device

A current measuring device, non-contact technology, applied in the direction of measuring device, only measuring current, using DC to AC conversion for measurement, etc., can solve the problems of trouble, detection of DC component, large deviation of magnetic core error rate, etc. To achieve the effect of convenience of use, elimination of saturation, and avoidance of mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can easily implement them.

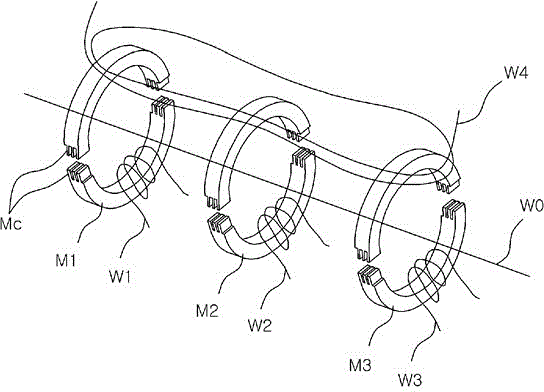

[0029] Figure 1 to Figure 4 It is a drawing for explaining an embodiment of a fluxgate type non-contact current measuring device of the present invention. figure 1 is a schematic diagram of the structure, figure 2 is a schematic diagram of the structure of a magnetic core wound with a coil, image 3 is the circuit diagram, Figure 4 It is a voltage waveform diagram of a current applied to magnetize the first magnetic core M1 and the second magnetic core M2.

[0030]The fluxgate type non-contact current measuring device of the present invention includes: three magnetic cores M1, M2, M3 that can respectively wind the wire W0 carrying the measured flowing current (the internal middle hole is through, so that the wire can pass through the magnetic core) ; Coils W1, W2, W3 wound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com