A sound cavity rubber product

A sound chamber and product technology, applied in the direction of the microphone port/microphone accessories, etc., can solve the problems of no processing, poor sound effect on the receiver side, weakened sound intensity, etc., to avoid the loss of sound wave scattering, low development cost, and development cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

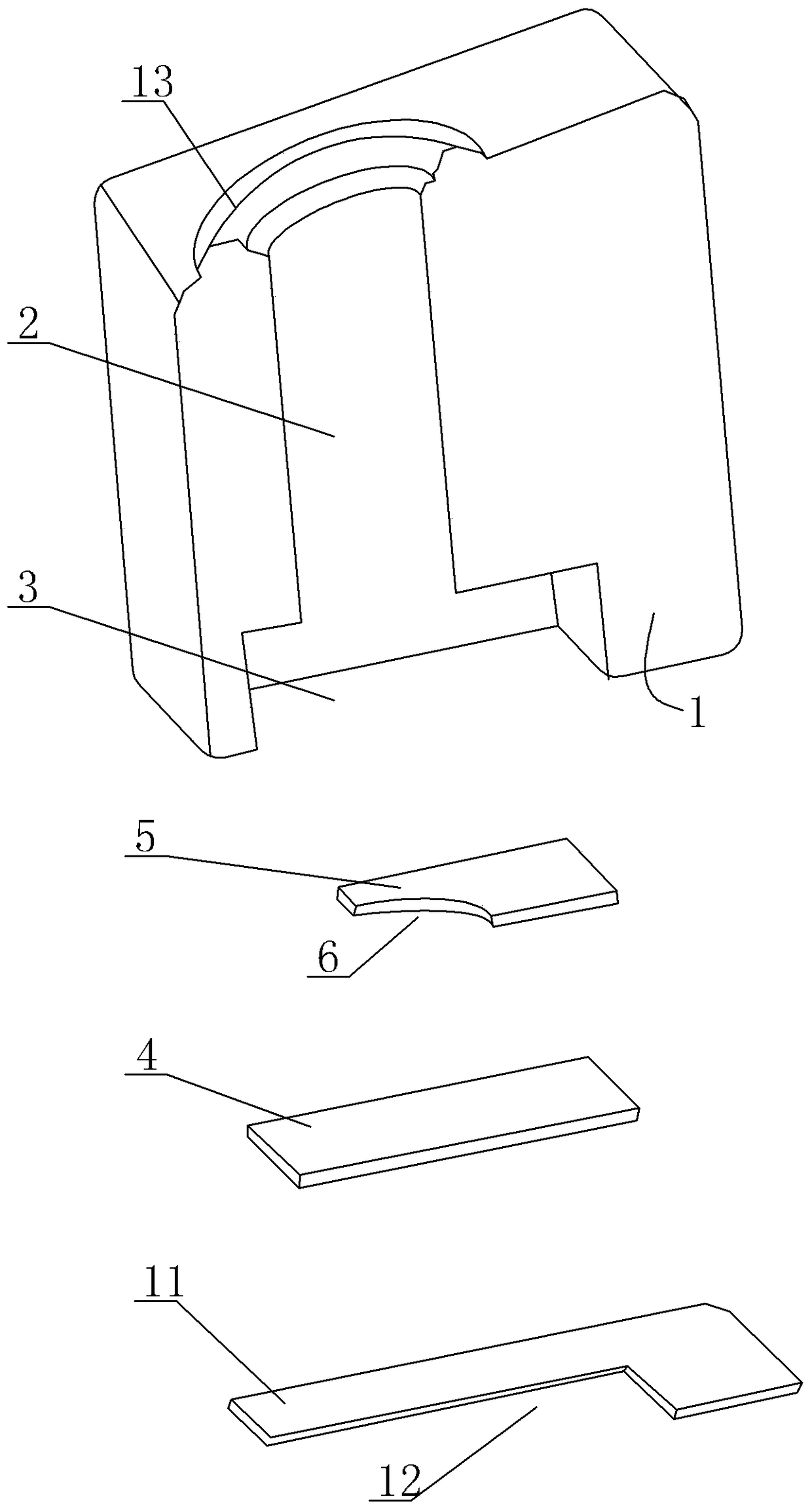

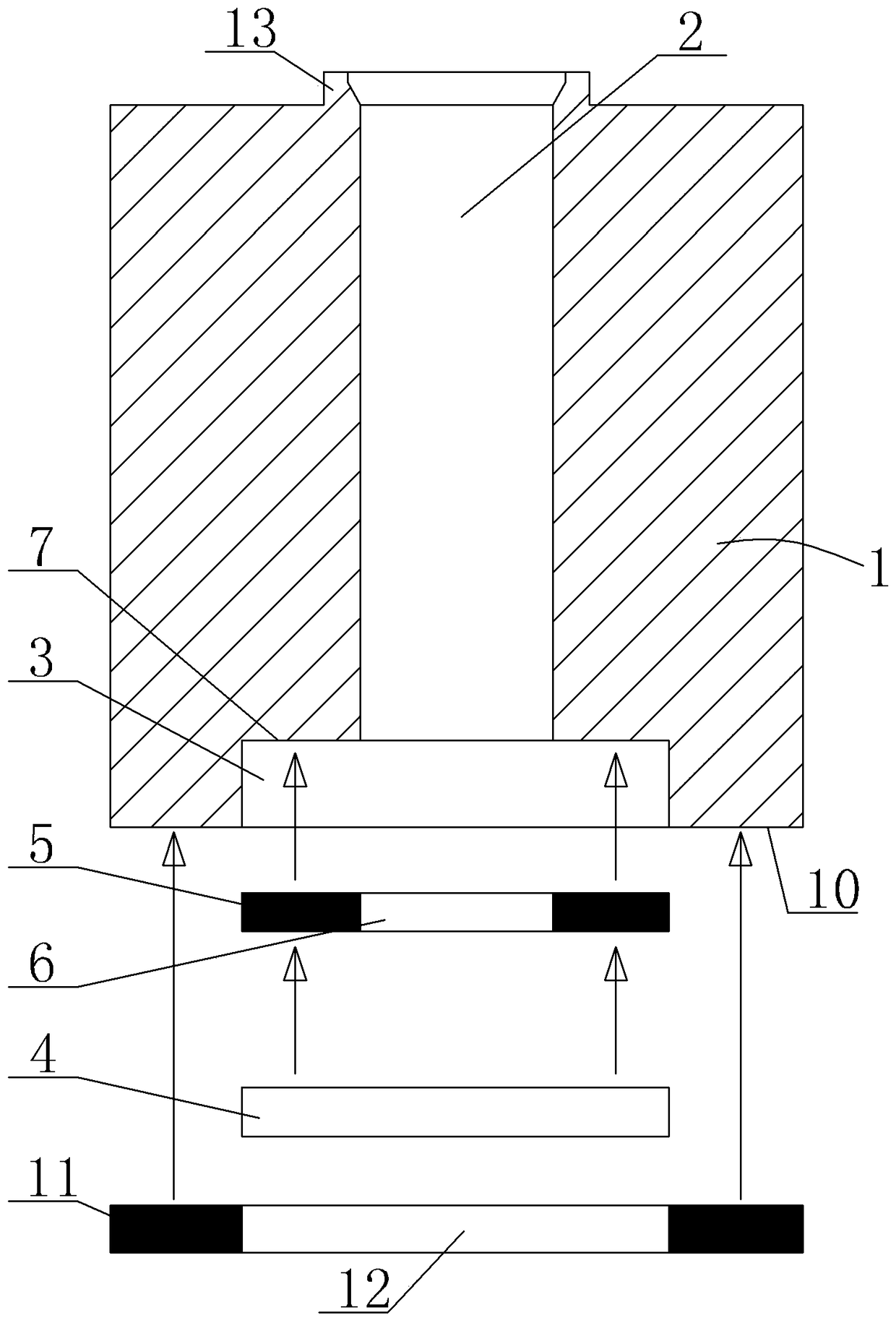

[0021] A sound cavity rubber product, see Figure 1 to Figure 4 : It includes a rubber body 1, the two sides of the rubber body 1 are designed according to the shape of the parts to be contacted, the rubber body 1 is formed by injection molding, the cavity shape of the mold determines the shape of the two sides of the rubber body 1, the shape of the mold The shape of the cavity is designed according to the shape of the part to be contacted, so that the end faces on both sides of the rubber body are respectively close to the corresponding parts to be contacted. The inside of the rubber body 1 is provided with a sound transmission cavity 2 connected on both sides, and the center of one side of the rubber body 1 Part of the recess forms the installation cavity 3, the sound transmission cavity 2 is connected to the installation cavity 3, the cross-sectional surface of the installation cavity 3 covers the cross-sectional surface of the sound transmission cavity 2, the installation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com