A combined plug-in board

A plug-in board, combined technology, applied in the direction of coupling device, two-part connection device, contact part, etc., can solve problems such as inability to use, and achieve the effects of convenient combination, good fixing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be further described through specific implementations in conjunction with the drawings.

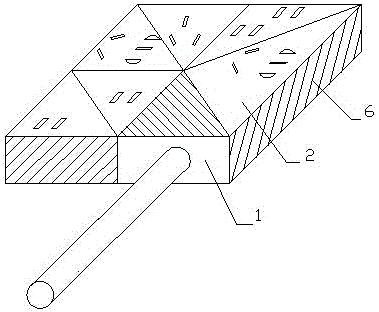

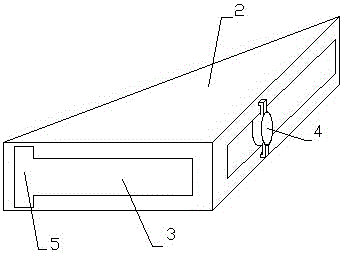

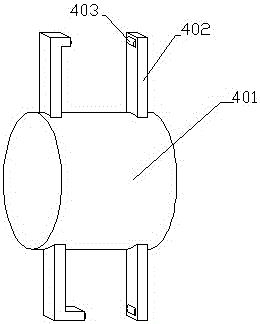

[0017] As shown in the figure, a combined plug-in board includes a power connection 1 and a plurality of plug-in units 2 with the same thickness. The plug-in units 2 can be set in various shapes, such as rectangle, square, triangle, diamond, and polygon. , Even irregular shapes, the panel of the plug-in unit 2 is provided with corresponding specifications and numbers of jacks according to the size and shape of the plug-in unit 2, and the power connection part 1 and the side of the plug-in unit 2 are all set with the same size The sliding groove 3 of the sliding groove 3, and conductive metal sliding rails are respectively arranged on the inner side walls on both sides of the sliding groove 3, the conductive metal sliding rail of the plug-in unit 2 is connected with the conductive contact piece at the socket, and the power connection part 1 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com