Bar material counting method

A counting method and bar technology, applied in the field of counting technology, can solve the problems of waste of human resources, labor injury, slow speed, etc., and achieve the effect of saving manpower and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

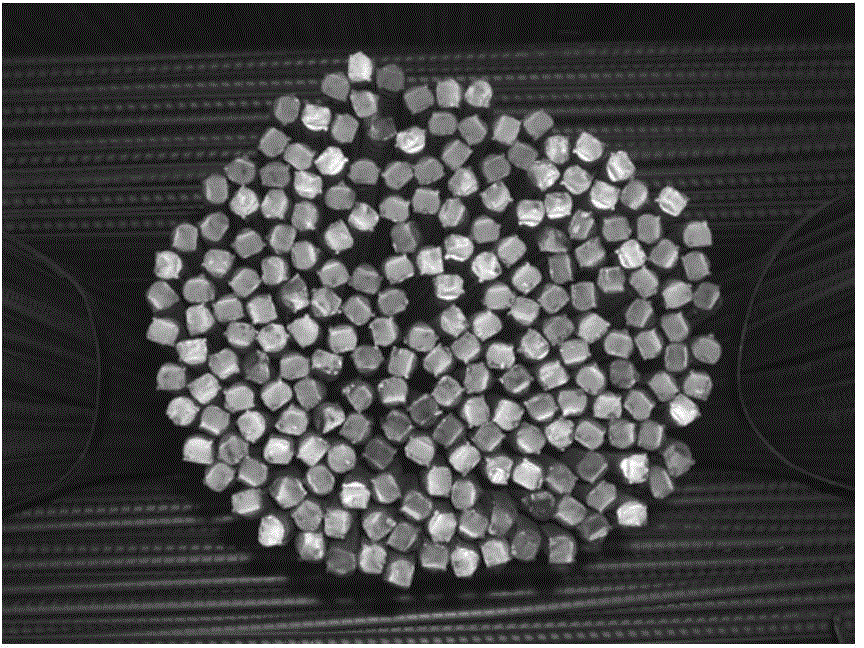

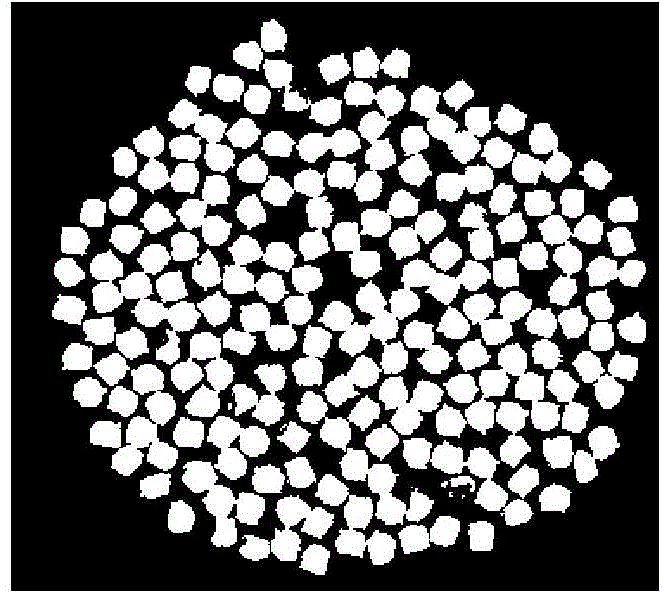

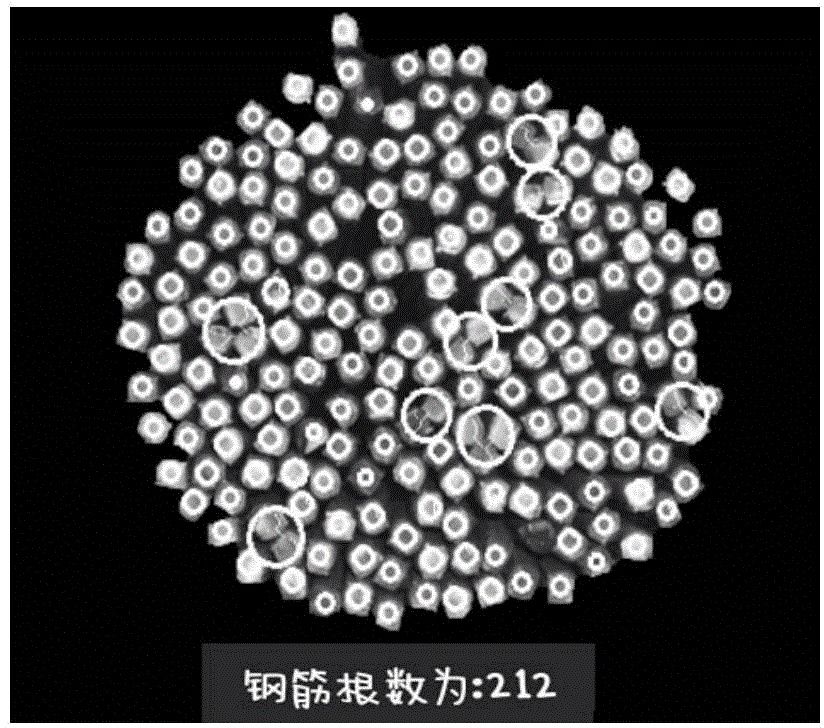

[0041] The present invention will be further described below in conjunction with the accompanying drawings. according to Figure 4 The process shown is to calculate the bar image. First, use a camera or a mobile phone to take a frontal photo of the cross-end face of the bar to be calculated, as shown in figure 1 As shown, this picture is used as the bar original image of the bar counting of the present invention. According to step A of the present invention, the original image of the bar is processed to obtain a binary image, such as figure 2 shown. If there is a pixel value of 255 in the binary image, it is white, otherwise it is marked as black. Then according to the enclosing circle of the bar end surface obtained by steps B and C of the present invention, mark the image of enclosing the circle, as image 3 As shown, the enclosing circle marked in this way can obtain the steel bar quantity according to step D of the present invention, and the original image of the bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com