Phase-change energy-storage water heater

A technology for phase change energy storage and water heaters, which is applied in the direction of heat storage heaters, fluid heaters, lighting and heating equipment, etc. Natural convection and other problems to achieve the effect of improving power utilization, compact structure, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

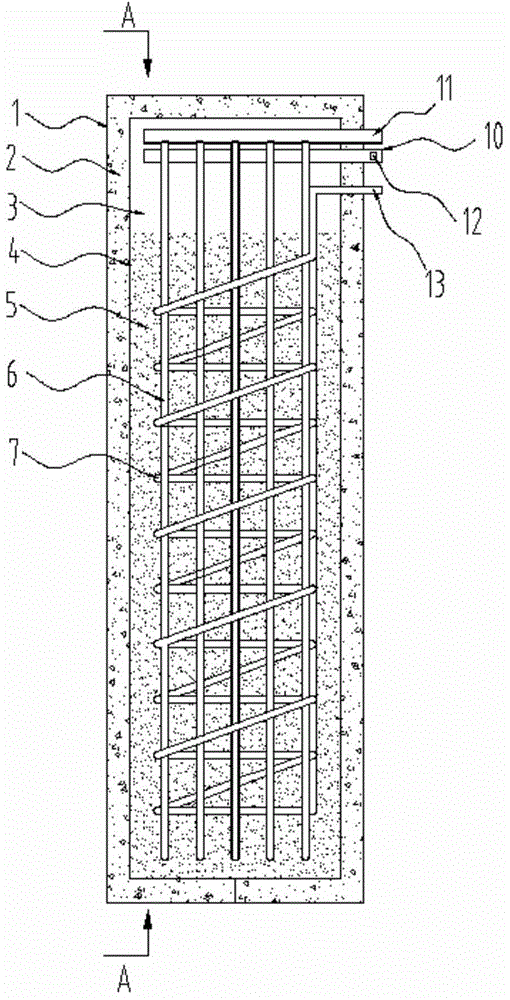

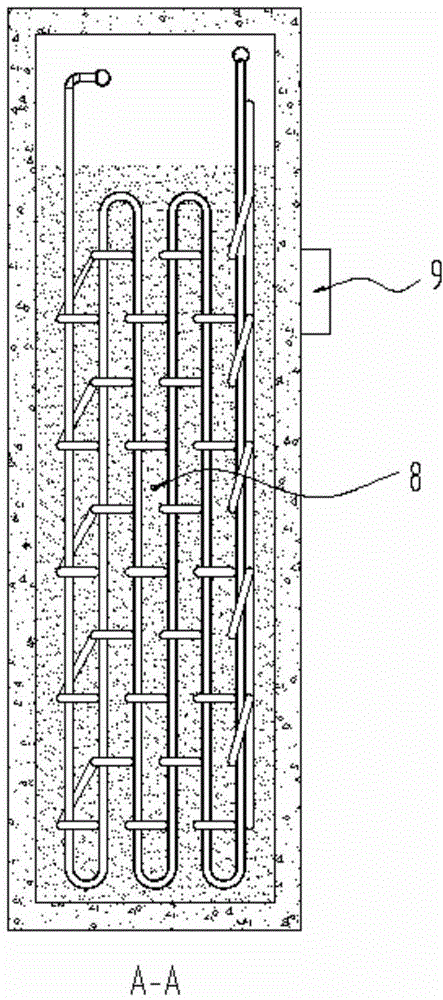

[0031] A phase change energy storage water heater, the structure is detailed in figure 1 , figure 2 , including a heat exchanger shell 1, the heat exchanger shell 1 has a thermal insulation material layer 2, the thermal insulation material layer is an inner tank 3, the inner tank 3 includes an inner tank shell 4, filled with a phase change material 5 , the phase change material 5 accounts for 80%-98% of the volume of the inner tank 3, the heat exchange coil 6 is embedded in the phase change material 5, and the electric heating mechanism 7 is evenly distributed in the phase change material 5, and the phase change material 5 is evenly distributed. A phase change material temperature sensor 8 is installed in the change material 5, the temperature sensor 8 and the electric heating mechanism 7 are electrically connected to the controller 9, the controller is installed on the heat exchanger shell 1, and one end of the heat exchange coil is connected to the cold water inlet 10, One...

Embodiment 2

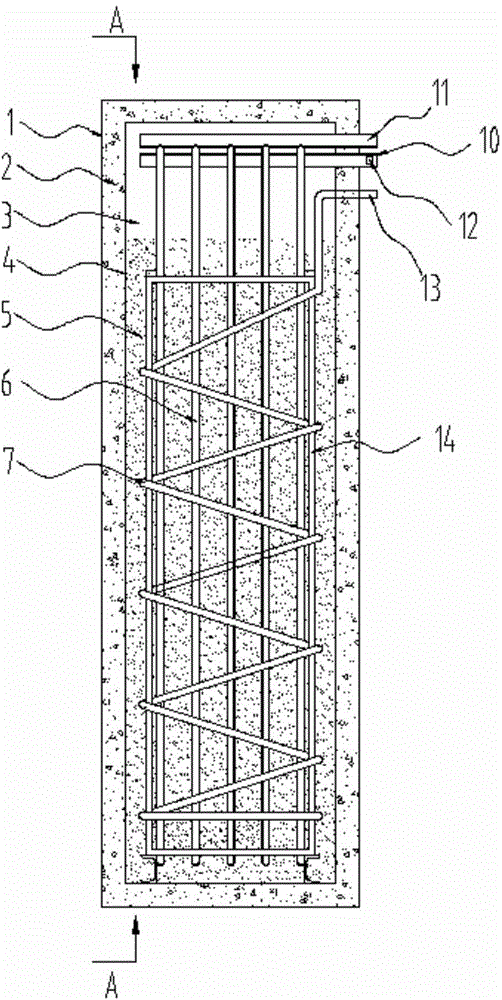

[0040] A phase change energy storage water heater, the structure is detailed in Figure 4 , Figure 5 , including a heat exchanger shell 1, the heat exchanger shell 1 has a thermal insulation material layer 2, the thermal insulation material layer is an inner tank 3, the inner tank 3 includes an inner tank shell 4, filled with a phase change material 5 , the phase change material 5 accounts for 80%-98% of the volume of the inner tank 3, the heat exchange coil 6 is embedded in the phase change material 5, the electric heating mechanism 7 is evenly distributed in the phase change material 5, and the temperature sensor 8 is fixed on the In the phase change material 5, the temperature sensor 8 and the electric heating mechanism 7 are electrically connected to the controller 9, the controller is installed on the heat exchanger shell 1, one end of the heat exchange coil is connected to the cold water inlet 10, and the other end is connected to the hot water outlet 11 , the hot wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com