A safety connector for a natural gas cylinder

A technology of connectors and natural gas, which is applied in the direction of safety valves, engine components, balance valves, etc., can solve the problems of safety hazards, valve opening and closing can not be intuitively reflected, valves forget to open, etc., to achieve the effect of preventing explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

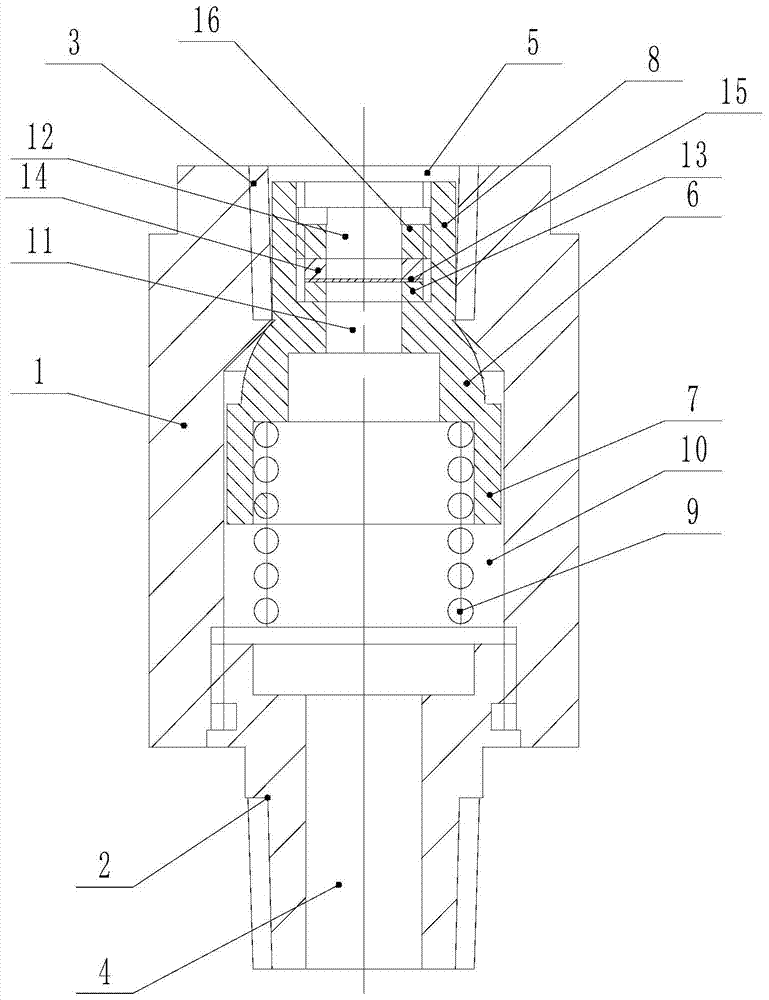

[0028] Such as figure 1As shown, a safety connector for a natural gas cylinder includes a housing 1, one end of the housing 1 is provided with an inlet threaded section 2, and the inlet threaded section 2 is provided with an inlet 4; the other end of the housing 1 is provided with a The outlet fixed section 3 is provided with an outlet 5 on the outlet fixed section 3, and an inner cavity 10 communicating with the inlet 4 and the outlet 5 is arranged in the housing 1. In this embodiment, the inlet threaded section 2 and the housing 1 The main body is split and fastened through screw connections. Of course, other connection methods can also be used between the inlet threaded section 2 and the main body of the housing 1, such as integral molding or welding. The inlet threaded section 2 is either an external thread or an internal thread, which mainly can be matched with the pipe interface on the gas cylinder. The outlet fixed section 3 is used to connect with devices such as safe...

Embodiment 2

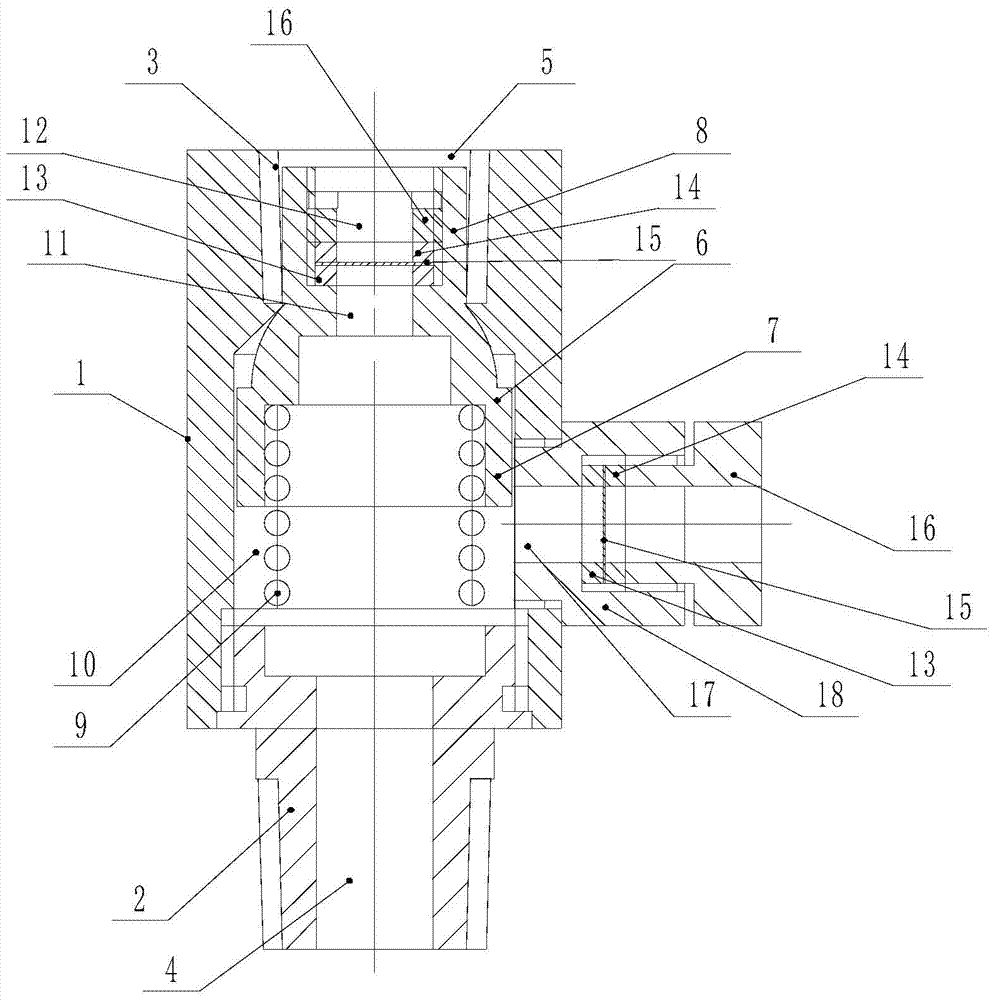

[0033] In this embodiment, the safety connector further includes a second pressure relief structure, the first pressure relief structure is mounted on the core 6 , and the second pressure relief structure is mounted on the housing 1 . Of course, if the first pressure relief structure is mounted on the housing 1 , then the second pressure relief structure is mounted on the core 6 .

[0034] The casing 1 is provided with a mounting screw hole 17 connecting the inner cavity 10 with the outside of the casing 1 , and a screw sleeve 18 is installed in the mounting screw hole 17 , and the second pressure relief structure is mounted on the screw sleeve 18 . The structure of the second pressure relief structure is the same as that of the first pressure relief structure. Certainly, the present invention discloses three kinds of pressure relief structures, so the first pressure relief structure and the second pressure relief structure can choose any one or any two of these three pressure...

Embodiment 3

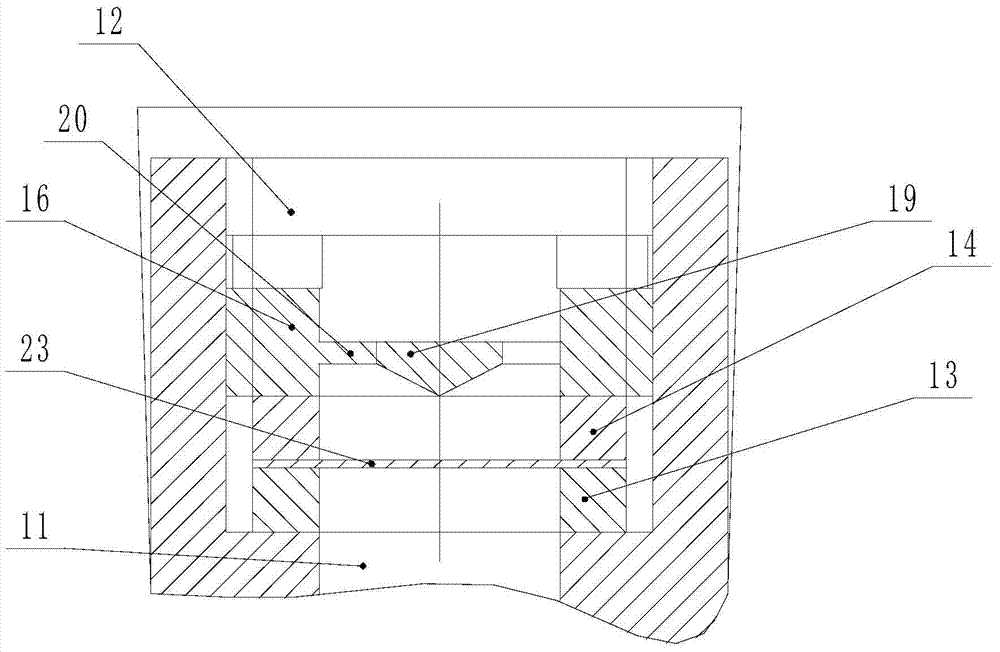

[0036] The basic structure in this embodiment is the same as that in Embodiment 1, except that the first pressure relief structure is different. In this embodiment, the first pressure relief structure includes an elastic bursting membrane 23, and the core body 6 is close to the outlet. The end of 5 (that is, the downstream end 8) is provided with a communication hole connecting the inner chamber 10 and the outlet 5, and the elastic bursting membrane 23 is fixed in the communication hole to separate the communication hole and the outlet 5, and the communication hole in the communication hole A piercing structure 19 is installed outside the elastic bursting membrane 23, and the piercing structure 19 cooperates with the deformed elastic bursting membrane 23 to puncture the elastic bursting membrane 23 when the inner chamber 10 exceeds the safety pressure.

[0037] And described communicating hole comprises the threaded hole section 12 of the large aperture that communicates with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com