Continuously variable transmission with synchronized gears

A technology of continuously variable transmission and synchronous gears, which is applied in belts/chains/gears, mechanical equipment, transmission devices, etc., and can solve problems such as inability to realize high-torque power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

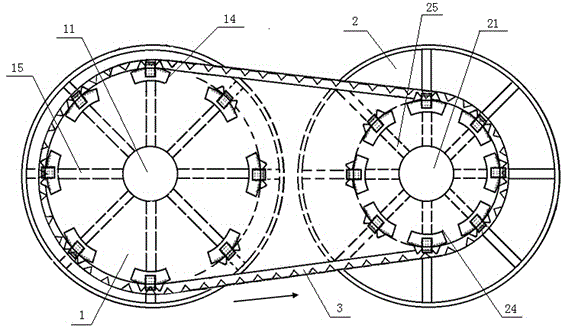

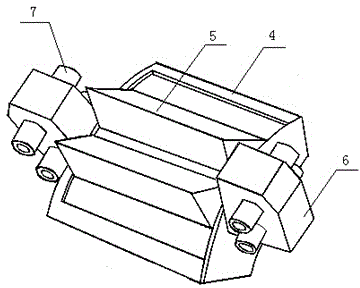

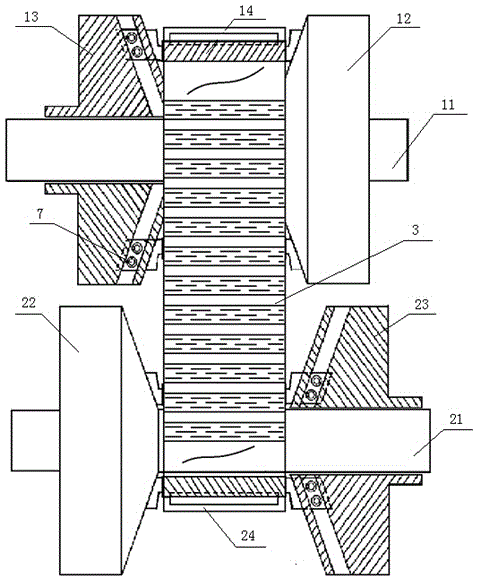

[0016] See Figure 1-Figure 3 , a continuously variable transmission with synchronous teeth, including a driving wheel 1, a driven wheel 2 and a power belt 3, the driving wheel 1 and the driven wheel 2 both include power shafts 11, 21, fixedly installed on one end of the power shafts 11, 21 The fixed vertebral body 12,22, the movable vertebral body 13,23 slidingly sleeved on the other end of the power shaft 11,21, eight synchronous support bodies 14,24 evenly distributed along the center of the power shaft 11,21; the fixed vertebral body 12 , 22 and the conical surfaces of the movable vertebral body 13, 23 are arranged oppositely;

[0017] The fixed vertebral bodies 12, 22 and the movable vertebral bodies 13, 23 are provided with eight variable-diameter tracks 15, 25 corresponding to the synchronous support bodies 14, 24 one-to-one, and the variable-diameter tracks 15, 25 run along the fixed vertebral bodies 12, 22 or the conical surface of movable vertebral body 13,23 is eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com