Moving type weighing platform trailer

A flat-bed trailer and sports technology, applied in the direction of motor vehicles, trolleys, multi-axis trolleys, etc., can solve problems such as large errors, inconvenient dragging by employees, and difficulty in turning flat-bed trailers to achieve the effect of avoiding weighing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

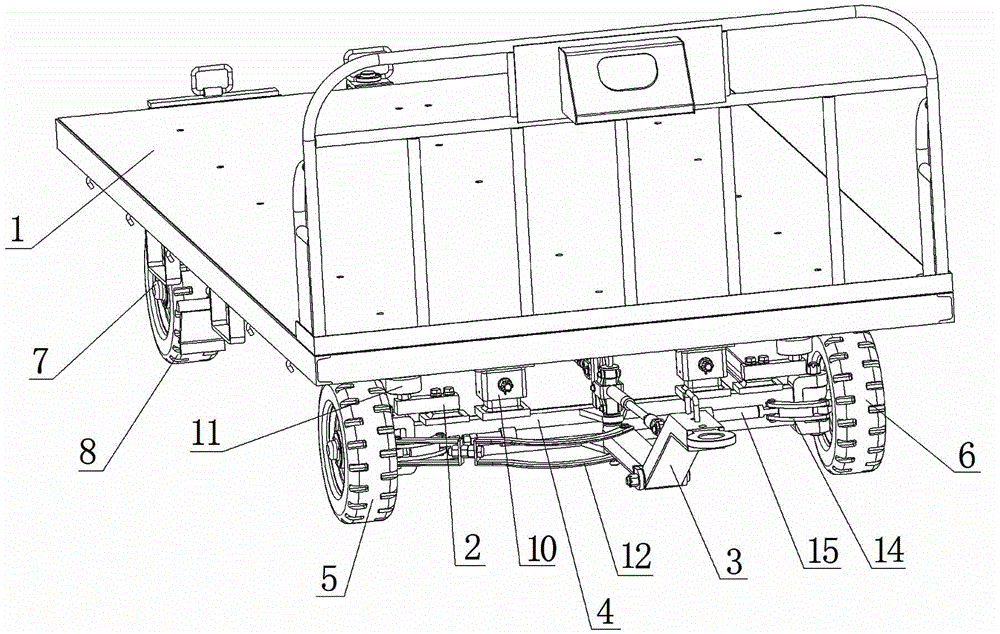

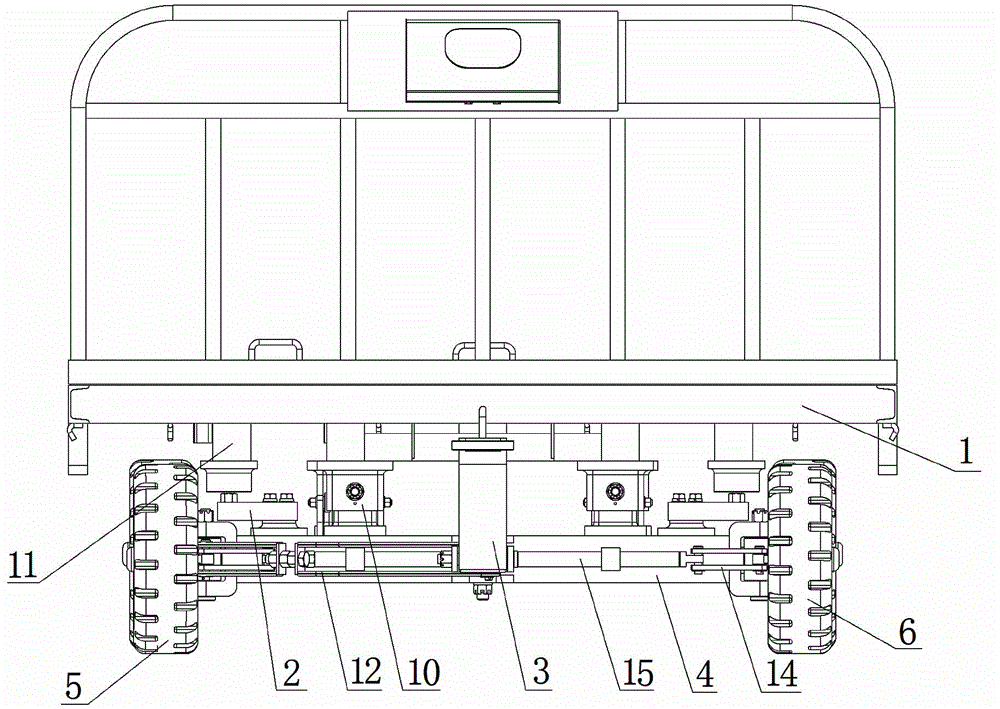

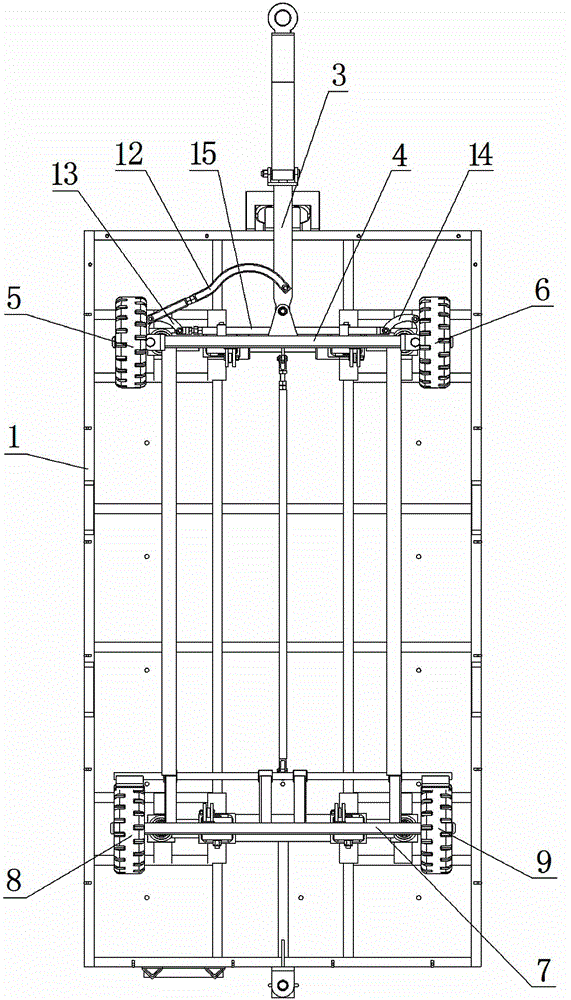

[0016] Such as Figure 1-3 Shown, a kind of sports weighing flat-bed trailer, it comprises trailer floor 1, steering mechanism, vertical guide I10, vertical guide II11, pressure sensor 2, controller, mop 3 and the front axle that is arranged under trailer floor 1 Assemblies and rear axle assembly, described front axle assembly is made up of main shaft I4, front left wheel 5 and front right wheel 6, and front left wheel 5 passes through the wheel hub of front left wheel 5 and main shaft I4 successively through pin and is connected on main shaft I4 The front right wheel 6 is connected to the other end of the main shaft I4 through the hub of the front right wheel 6 and the main shaft I4 through pins, and the rear axle assembly is composed of the main shaft II7, the rear left wheel 8 and the rear right w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com