Packaging scale feeding device

A technology of feeding device and packaging scale, which is applied in packaging and other directions, can solve the problems of weighing error of packaging scale and increase of drop, and achieve the effect of ensuring precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

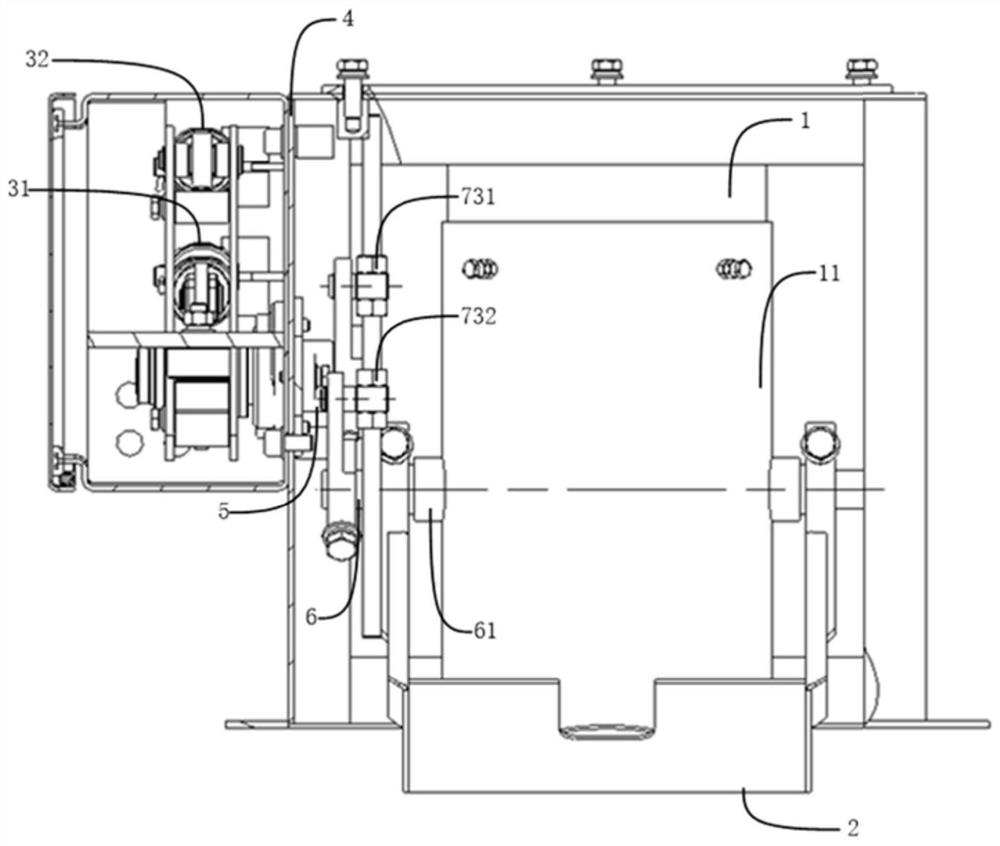

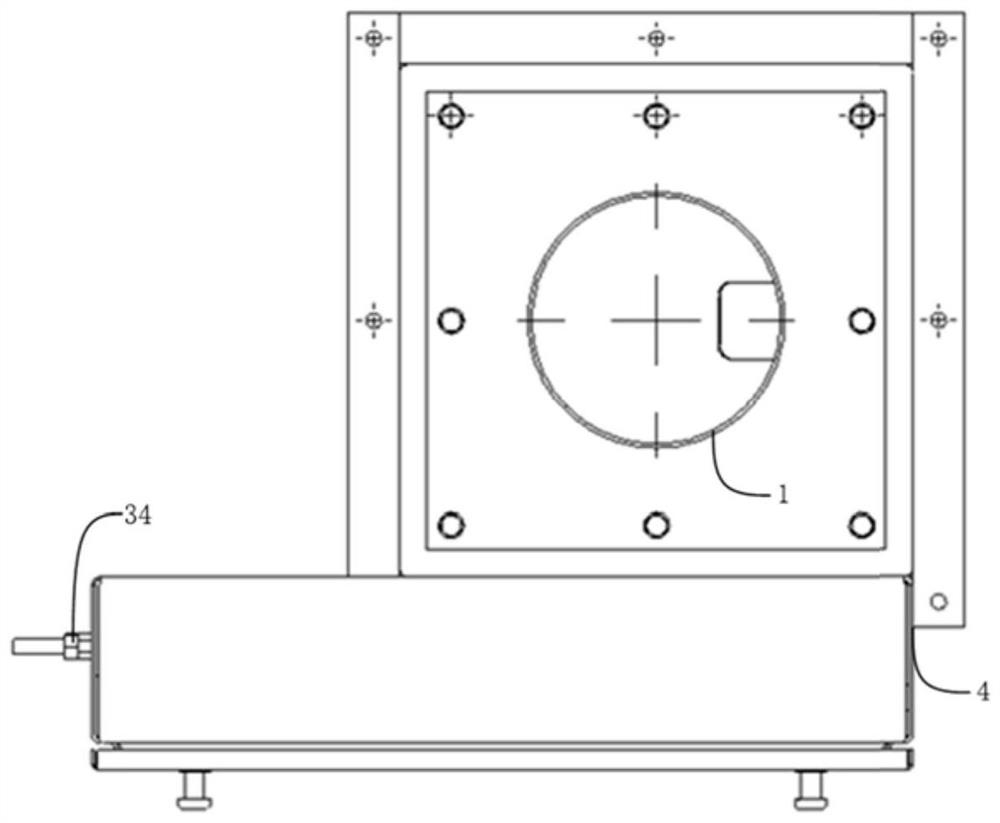

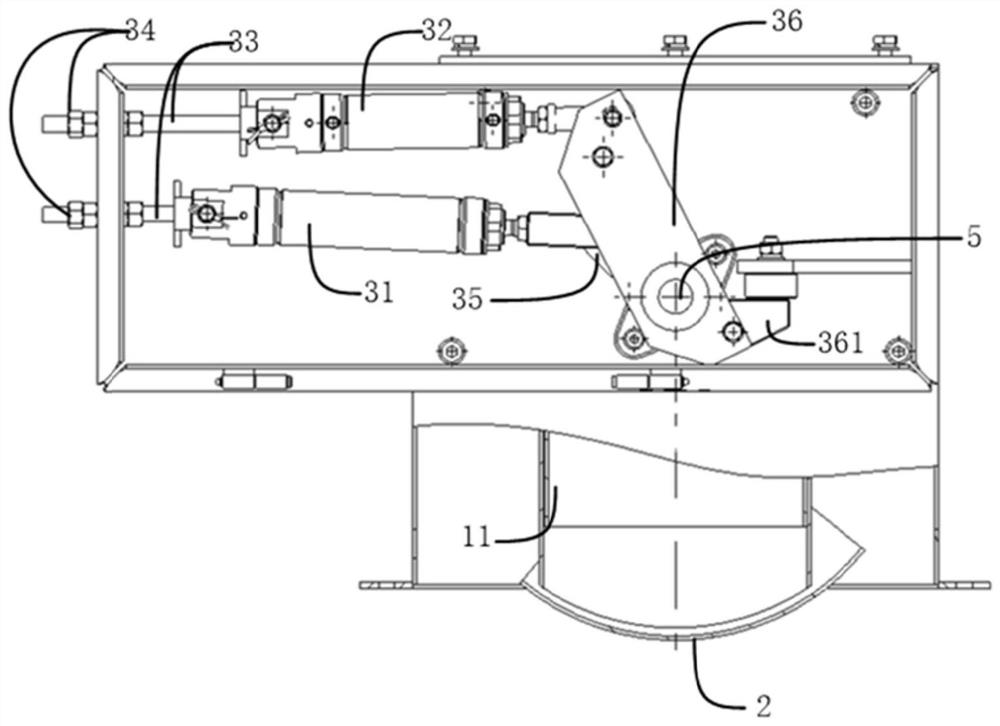

[0051] A packing scale feeding device in this embodiment includes a feeding pipe, a feeding door and an air cylinder arranged in the feeding housing. according to figure 1 and figure 2 It can be seen from the front view and the top view that the feeding pipe 1 and the material door 2 are located in the same vertical direction, and the cylinders 31, 32 are located on the side of the feeding pipe 1 and the material door 2. A first rotating shaft 5 passes through the feed hopper shell 4 between the feed pipe 1 side and the cylinders 31 , 32 sides, and is hinged on the feed hopper shell 4 . Simultaneously, a second rotating shaft 6 positioned at the feeding pipe 1 side is provided, and a bearing seat 61 is fixedly arranged on the outer surface of the outermost feeding pipe 11 by means such as welding, and the second rotating shaft 6 is fixedly connected to the material gate 2. And it is hinged in the bearing seat 61 to realize the hinged connection between the feeding pipe 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com