Hoisting rod foam model processing device

A foam model and processing device technology, applied in metal processing and other directions, can solve the problems of low work efficiency and poor quality, and achieve the effect of convenient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

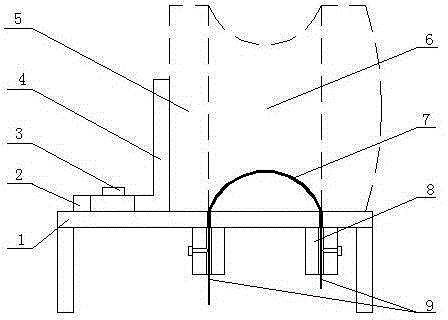

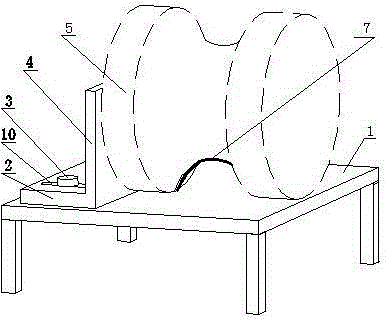

[0011] As shown in the figure, the left part of the plane workbench 1 is equipped with a vertical positioning vertical plate 4, and the lower part of the positioning vertical plate 4 is bent outward at 90 degrees to form a joint surface 2 with the workbench 1, and the joint surface 2 is opened. Horizontal positioning bar mouth 10 is arranged, and positioning pin 3 is connected with workbench 1 on the positioning bar mouth 10; Left and right two wire fixing plates 8 are housed on the below of positioning riser 4 right side workbench 1, and wire fixing plate 8 is equipped with Lead 9, arched heating wire plate 7 is housed above the workbench 1 above lead fixing plate 8, and the two ends of heating wire plate 7 join with lead 9.

[0012] When working, according to the design requirements of the foam model, through the positioning bar opening 10 on the connecting surface 2, adjust the positioning vertical plate 4 left and right and lock it with the positioning pin 3, then adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com