A sterilization device

A sterilizing device and tank technology, applied in heating and other directions, can solve the problems of low degree of automation, inapplicability of automatic production lines, and inability to sterilize in large quantities, so as to achieve the effect of improving utilization rate and facilitating production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

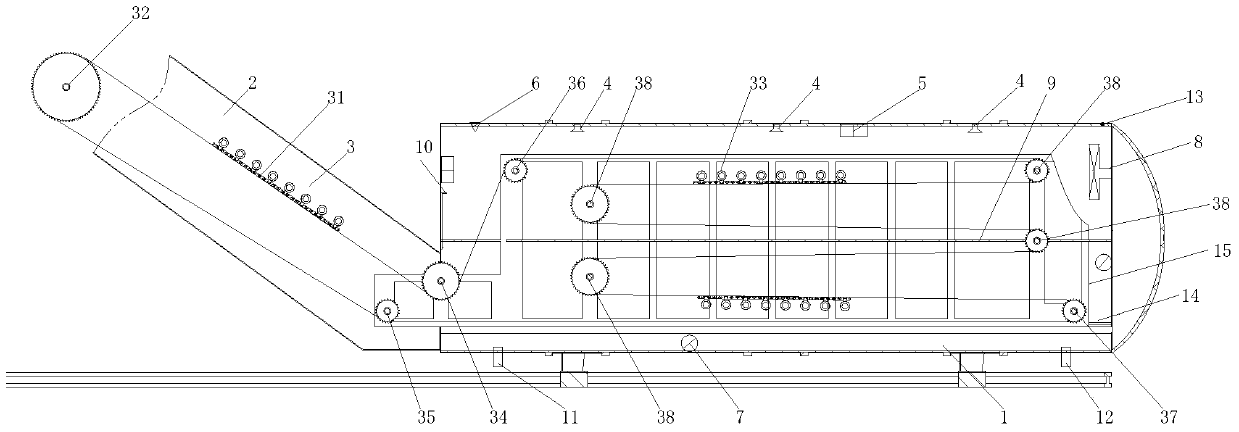

[0022] like figure 1 As shown, a sterilizing device includes a horizontally arranged tank body 1 , a feeding box body 2 and a material conveying device 3 .

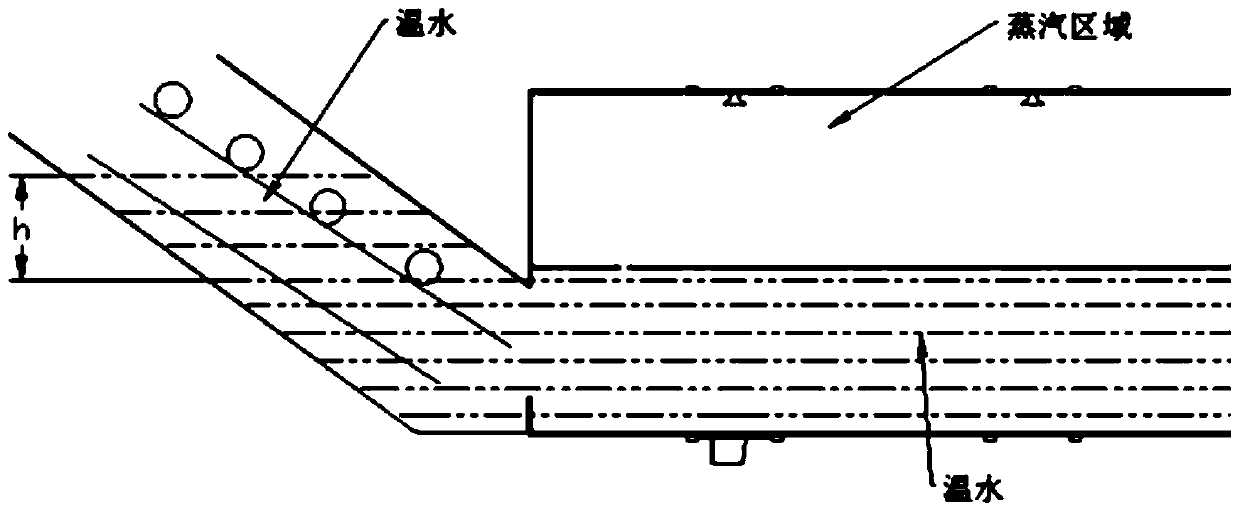

[0023] The lower part of one end of the tank body 1 is provided with an inlet and outlet, and the feeding box 2 is sealed and connected to the inlet and outlet of the tank body 1. The tank body 1 is provided with a horizontal partition 9 higher than the apex of the inlet and outlet, and the partition 9 The inner cavity of the tank body 1 is divided into an upper cavity and a liquid-sealed cooling cavity, and the separator 9 is provided with feeding holes at both ends of the tank body 1, and the feeding port of the feeding box body 2 is higher than the top of the tank body 1 Location.

[0024] The material conveying device 3 includes two conveying chains 31, a pair of coaxially arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com