Method for preparing silica gel diaphragm and silica gel diaphragm

A silicone diaphragm, liquid silicone technology, applied in the direction of diaphragm fixation/tightening, flat diaphragm, polymer material diaphragm, etc., can solve the problems of thick diaphragm thickness, limited injection molding conditions, high cost, and achieve vibration The effect of various membrane forms, simple molding methods, and controllable diaphragm thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

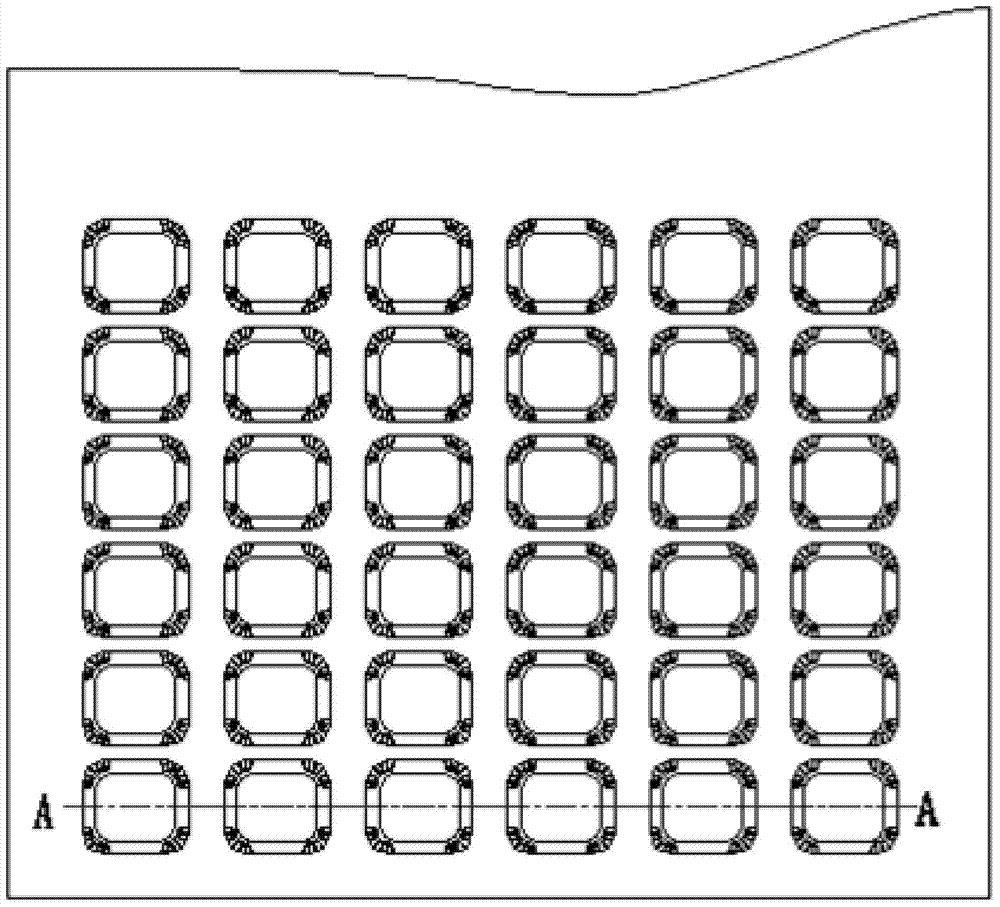

[0041] figure 1 A flow chart of a method for preparing a silica gel diaphragm provided by an embodiment of the present invention, the method includes:

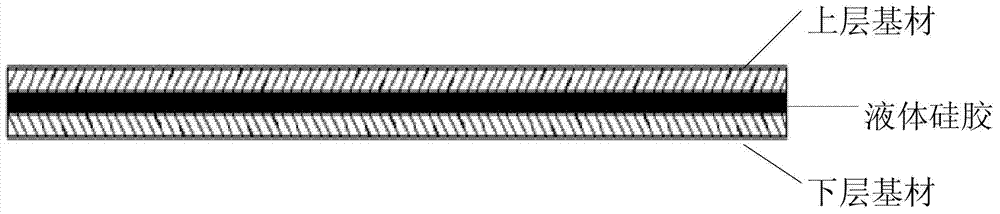

[0042] S100, forming a composite tape by calendering two layers of substrates and liquid silica gel, and the liquid silica gel is located between the two layers of substrates.

[0043] Such as figure 2 As shown, it is a schematic diagram of the composite tape prepared by calendering provided by the embodiment of the present invention, and the liquid silica gel in the figure is between the upper substrate and the lower substrate.

[0044] Among them, calendering refers to the process of making semi-finished products such as film through the nip between two rollers that are relatively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com