Translatable lead guide mechanism

A technology of guiding mechanism and translation mechanism, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of poor working environment, low production efficiency, high labor intensity, etc., to improve production efficiency, reduce labor, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

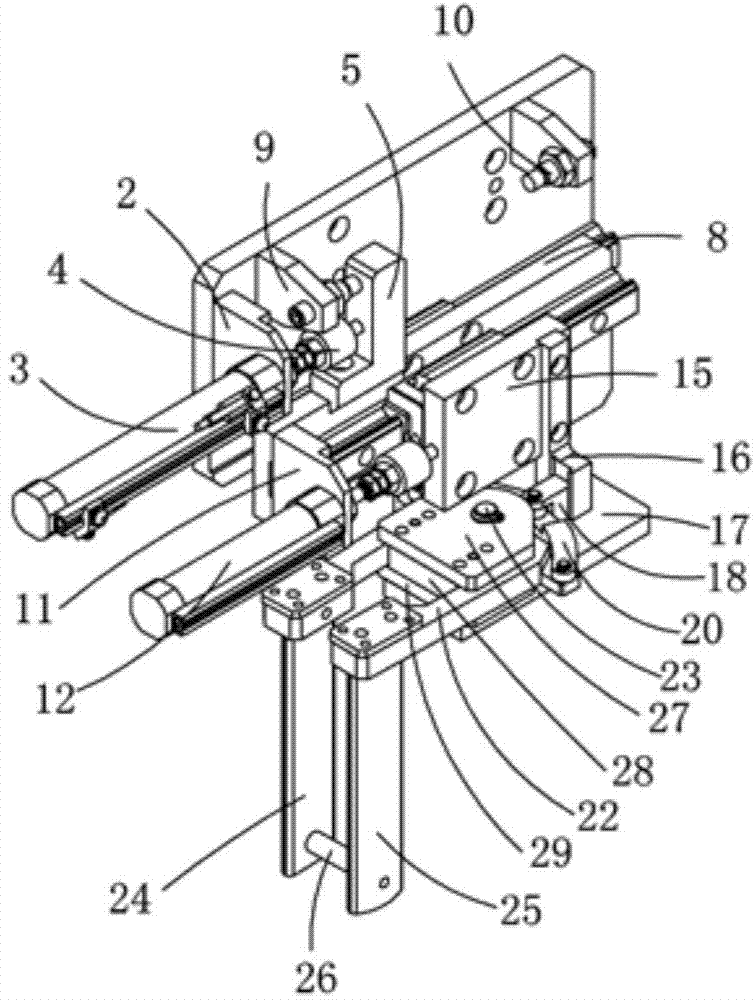

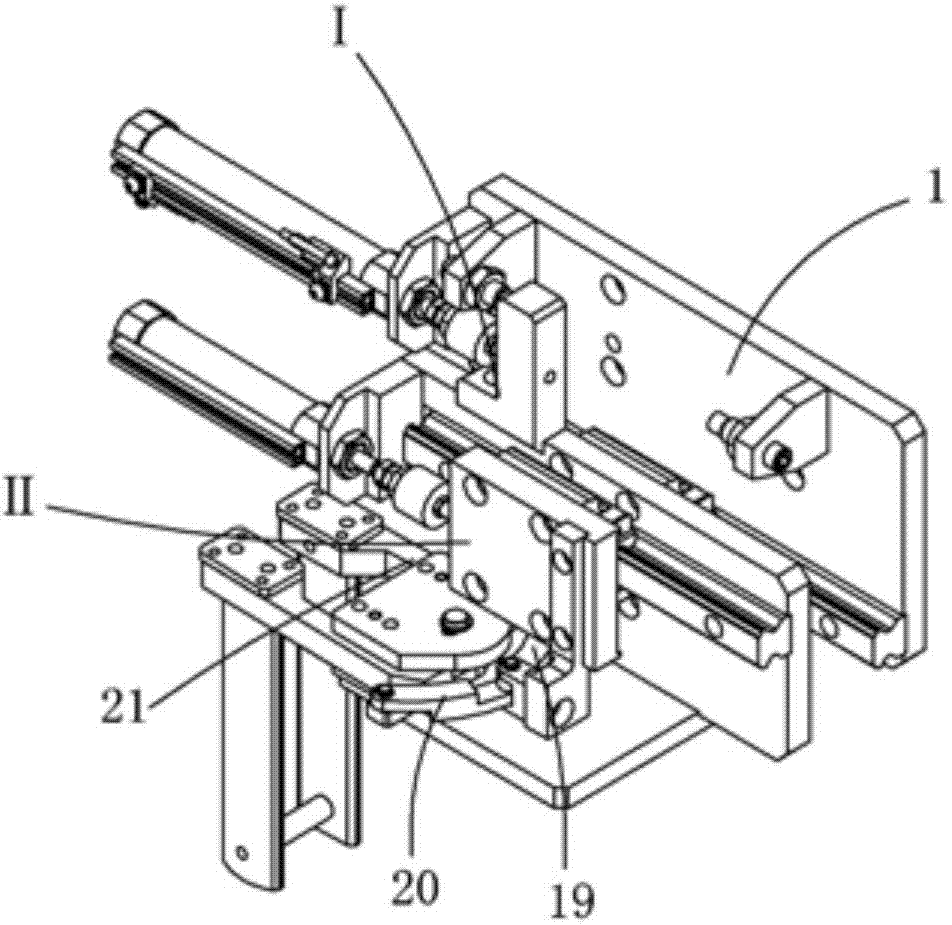

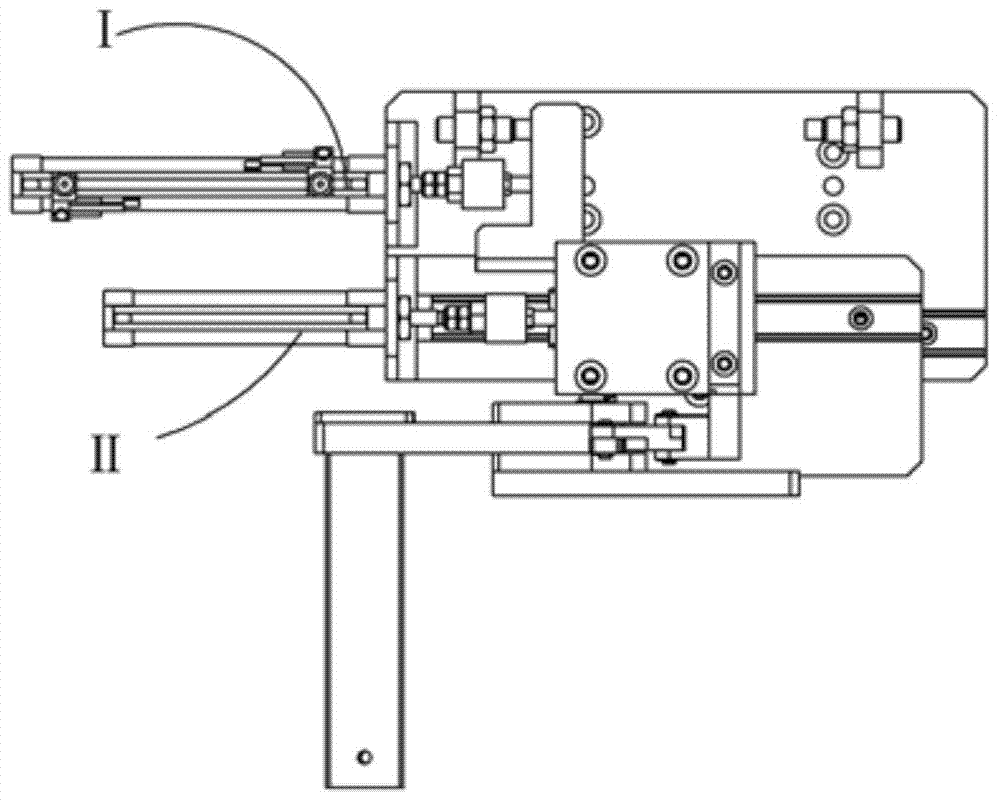

[0021] Examples, see attached Figure 1~6 , a translatable lead wire guiding mechanism, which includes a fixed plate 1, a translation mechanism I is installed on the fixed plate, the translation mechanism includes a translation cylinder fixing seat 2, and the translation cylinder fixing seat is fixed on the fixing plate, A translation cylinder 3 is installed on the fixed seat of the translation cylinder, and the front end of the piston rod of the translation cylinder is connected with a translation connection block 5 through a translation cylinder joint 4; Block 7, a slide plate 8 is installed on the translation slide block, and the translation connection block is connected with the slide plate. The upper parts of the left and right sides of the fixed plate are respectively equipped with buffers 10 through the buffer fixed block 9, and the drive of the translation cylinder can drive the translation connection block to move along the slide rail, so that the slide plate moves al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com