Fiber friction coefficient testing device and testing method thereof

A friction coefficient and testing device technology, which is applied to measuring devices, mechanical devices, instruments, etc., can solve the problems of small force value measurement range, low force value resolution, operation error, etc., and achieve force measurement accuracy and range improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

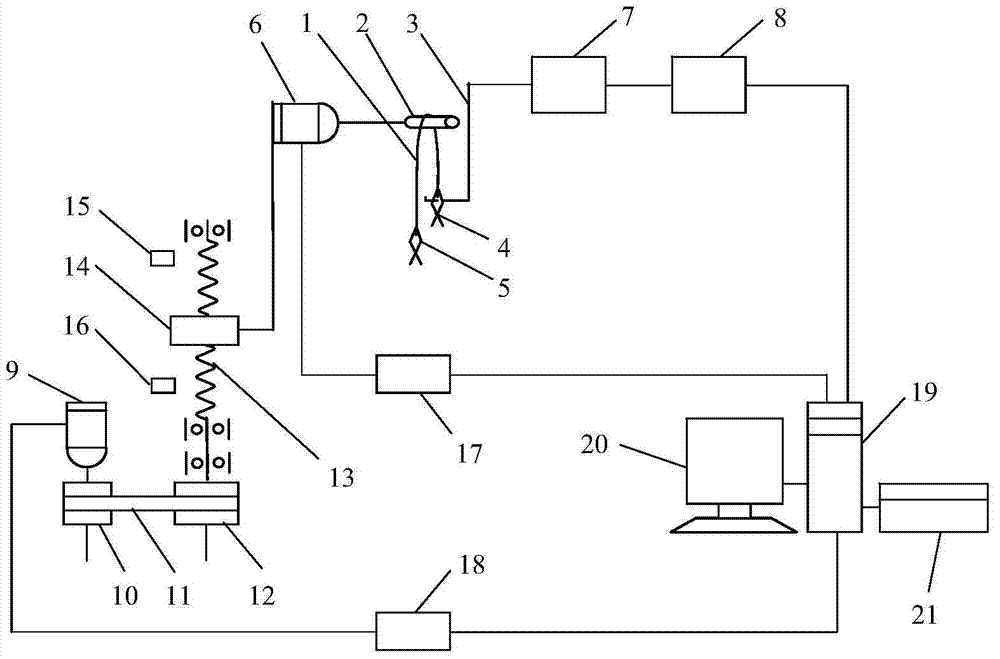

[0030] see figure 1 , which is a structural schematic diagram of a preferred embodiment of a fiber friction coefficient testing device of the present invention. As shown in the figure: it includes friction roller 2, hook 3, first tension clamp 4, second tension clamp 5, first stepper motor 6, force sensor 7, amplifier 8, first pulse distributor 17, computer 19 and Its input and output equipment; wherein: the friction roller 2 is hung with a sample 1 with a wrapping angle; the first tension clamp 4 clamps one end of the sample 1, and the first tension clamp 4 is connected to the force sensor 7 through the hook 3 ; The force value resolution of the force sensor 7 is 0.25×10 -3 Below cN, the measuring range of force value is 1000×10 -3 More than cN; the force sensor 7 is further connected with the computer 19 through the amplifier 8; the second tension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com