Vibration test device for two-stage fixed axis gear drive mechanism

A technology of gear transmission mechanism and vibration test, which is applied in the direction of vibration test, machine/structural component test, measuring device, etc., which can solve the problems of gear or other component damage, error, reduction of machine safety, reliability and working quality, etc. , to achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

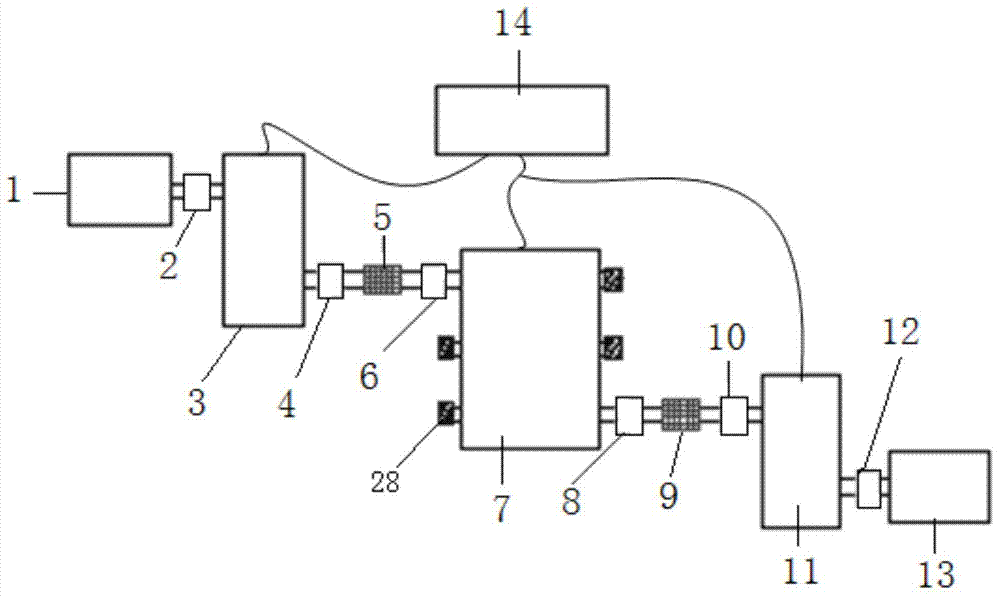

[0020] A two-stage fixed-axis gear transmission mechanism vibration test device, the structure is as follows figure 1 As shown, it includes a first pump motor 1 , a gearbox 3 , a first torque sensor 5 , a gearbox 7 , a second torque sensor 9 , a reduction gearbox 11 and a second pump motor 13 connected in sequence. The speed increasing box 3, the gearbox 7 and the speed reducing box 11 are respectively connected with the lubricating pumping station system 14.

[0021] A first diaphragm coupling 2 is arranged between the first pump motor 1 and the gearbox 3 .

[0022] A second diaphragm coupling 4 is arranged between the gearbox 3 and the first torque sensor 5 .

[0023] A third diaphragm coupling 6 is arranged between the first torque sensor 5 and the gearbox 7 .

[0024] A fourth diaphragm coupling 8 is arranged between the gearbox 7 and the second torque sensor 9 .

[0025] A fifth diaphragm coupling 10 is arranged between the second torque sensor 9 and the reduction gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com