An ultra-precise dynamic balancing device suitable for micro rotors

A micro-rotor, ultra-precision technology, used in static/dynamic balance testing, measuring devices, machine/structural component testing, etc. , Enhance the stability and meet the needs of different types of rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

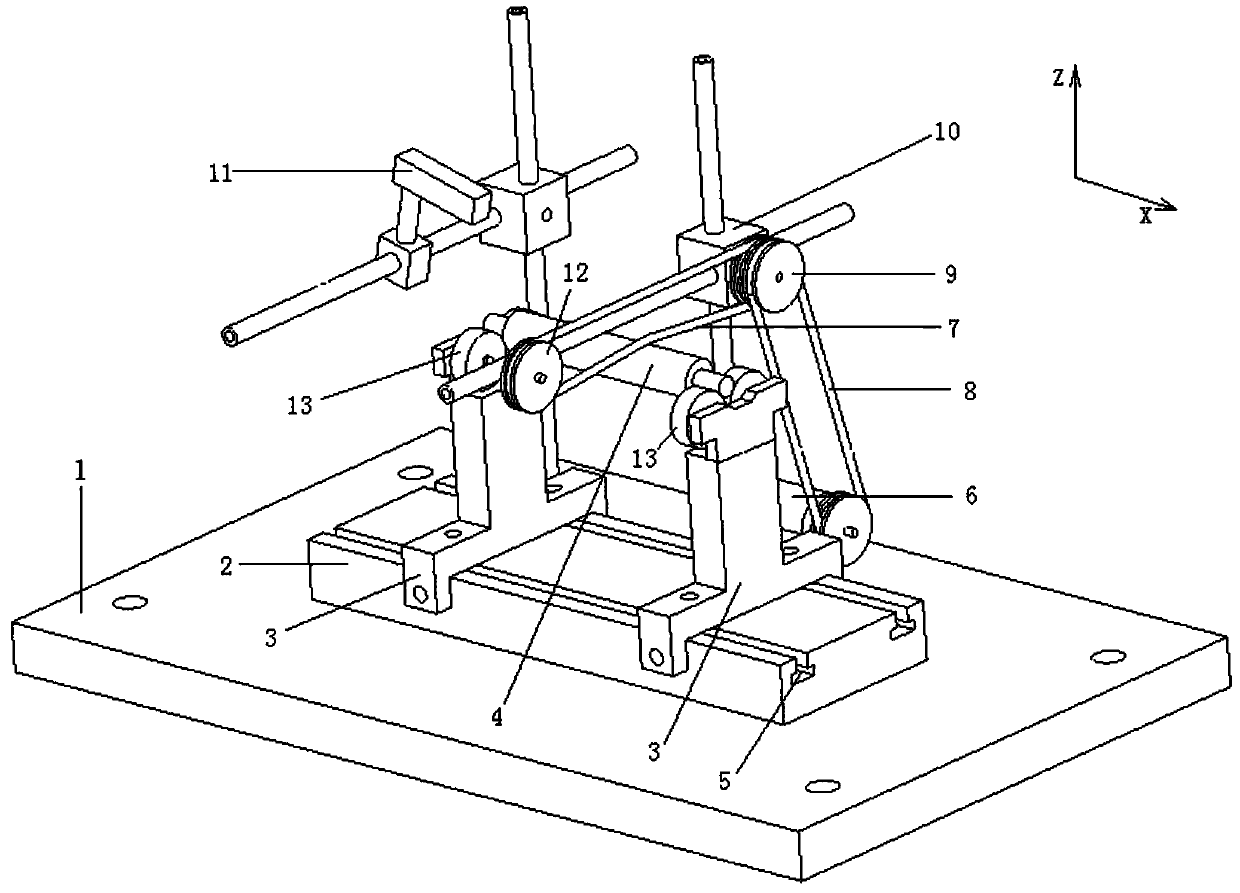

[0025] The present invention provides a figure 1 The shown ultra-precise dynamic balancing device suitable for micro-rotors includes a bottom plate 1, and also includes a device fixing part, a rotor support frame part, a rotor driving mechanism part and an unbalance vibration monitoring part;

[0026] The device fixing part includes a rotor 4, a base 2, a guide rail 5, and a support frame fixing frame 3; wherein the support frame fixing frame 3 is slidingly connected to the base 2 fixed on the bottom plate 1, and the support frame fixing frame 3 can be realized The position on the base 2 is fixed, specifically the support frame fixing frame can be fixed on the guide rail by pins.

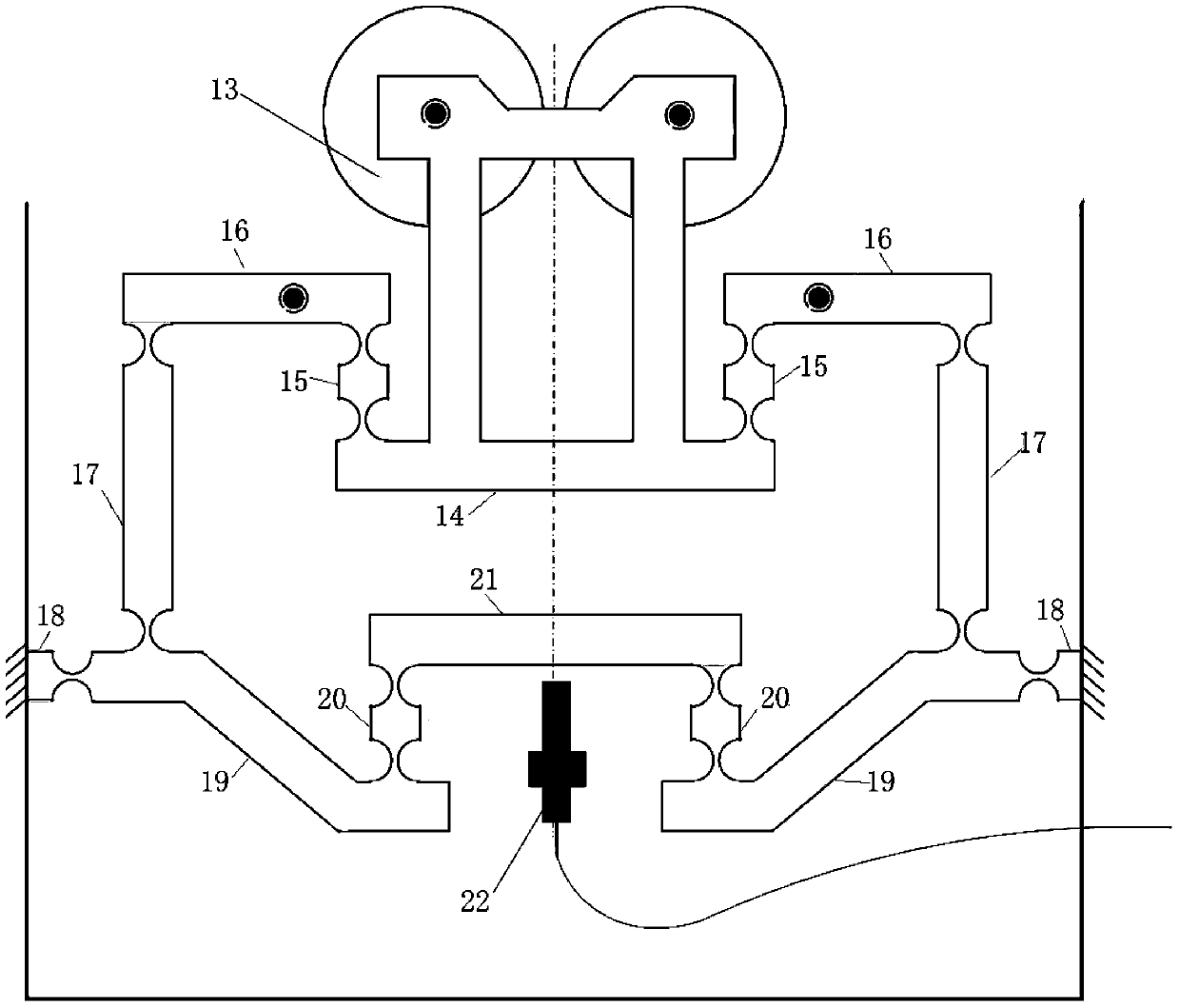

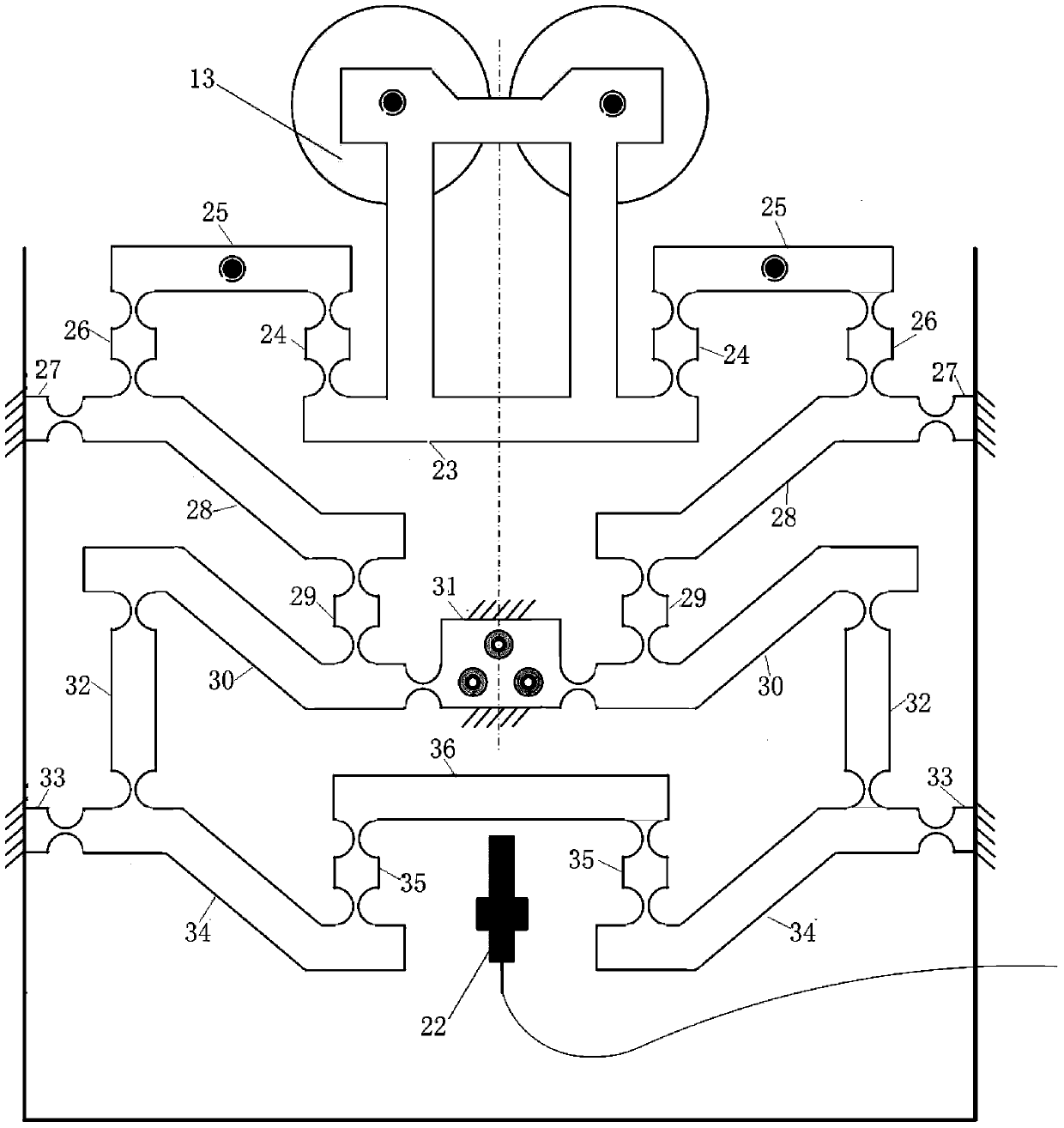

[0027] The rotor support frame part is an unbalanced vibration support frame for realizing the rotor vibration displacement amplification function located in the support frame fixing frame 3; the two ends of the rotor 4 are respectively mounted on a group of rollers 13, and The roller 13 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com