Automatic sampling system and control method of fermentation tank

A technology of automatic sampling and control methods, which is applied in the direction of biological material sampling methods, sterilization methods, and methods of supporting/immobilizing microorganisms, etc., which can solve the problems of small sampling volume, pollution, and the need for tens of days

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

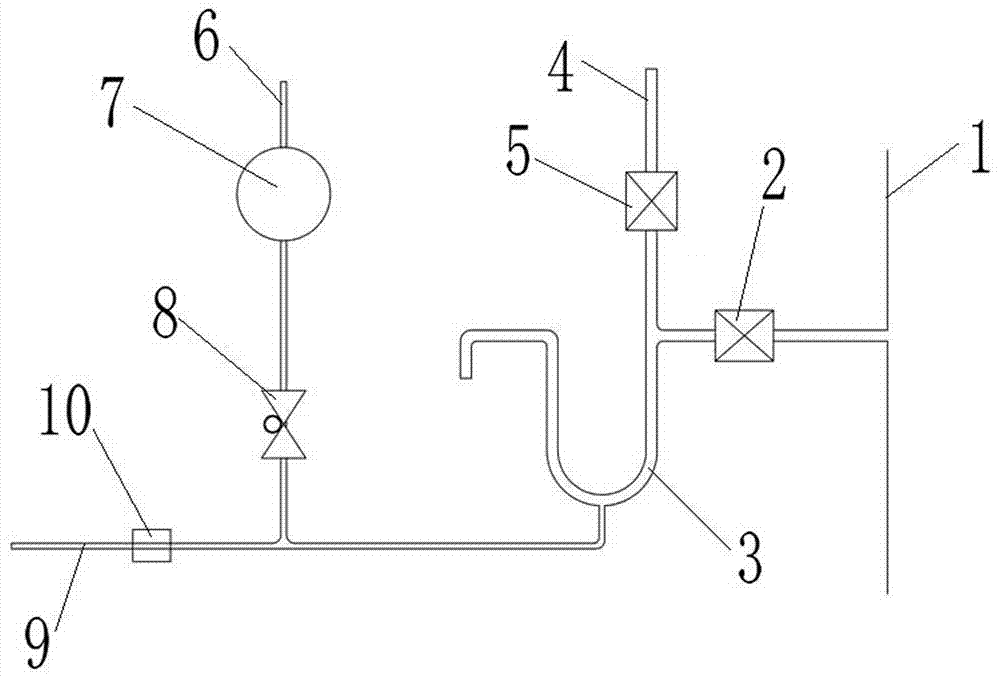

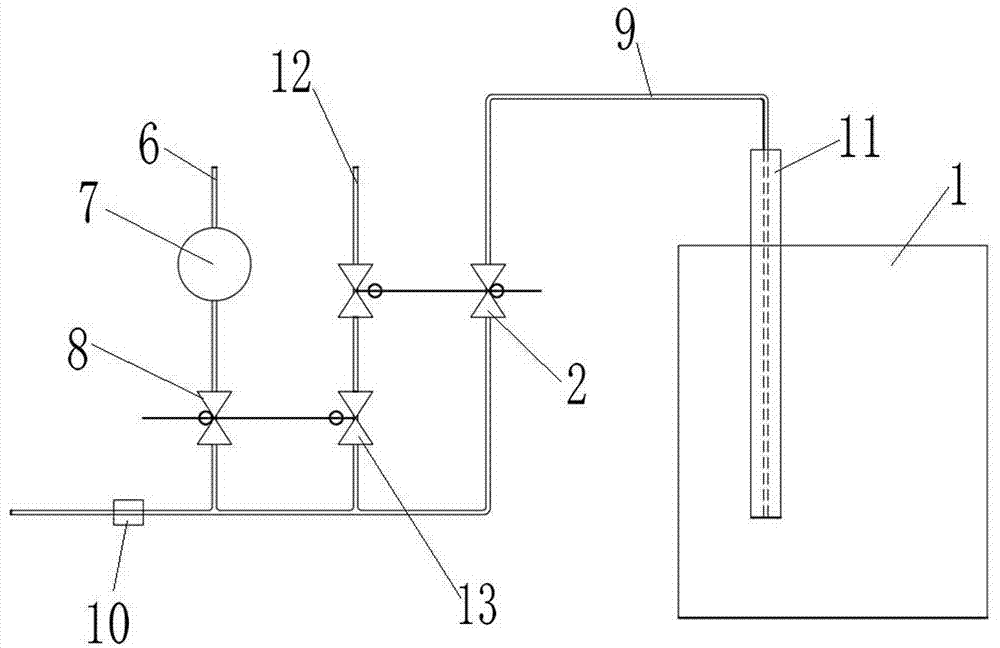

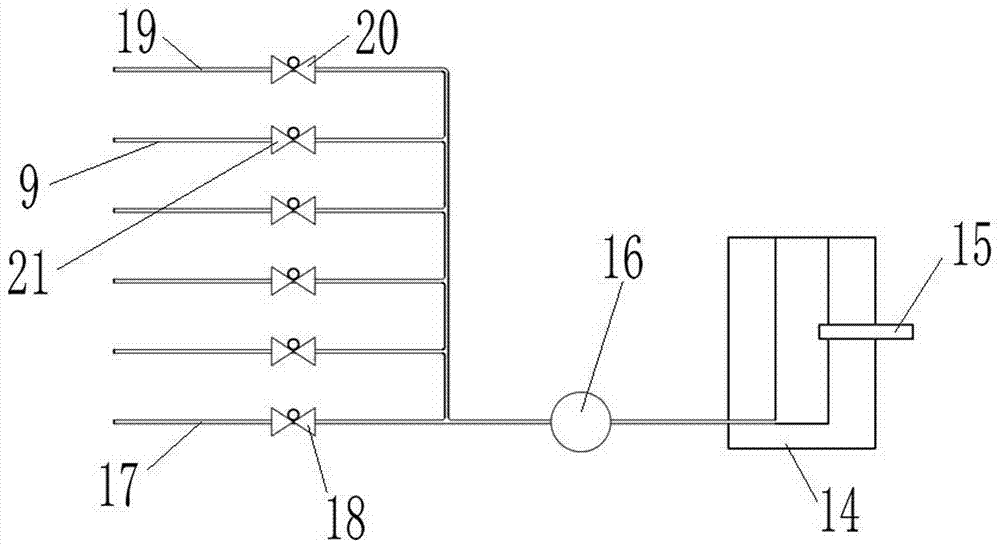

[0033] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

[0034]An automatic sampling system for a fermenter, comprising: a sampling device, connected to the fermenter 1 through a sampling valve 2, for taking out the fermented liquid from the fermenter 1; a sampling pool 14, which is internally equipped with a conductivity type for detecting liquid Liquid sensor 15; delivery pipe 9, one end of which is connected to sampling pool 14 through bidirectional sampling pump 16 through pipeline valve 21, and the other end is connected to sampling device through liquid sensor 10; waste liquid pipeline 17, one end of which passes through waste liquid valve 18 The two-way sampling pump 16 is connected to the sampling pool 14, and the other end is connected to the waste liquid bottle; and the sterile air pipeline 6 is connected to the delivery pipe 9 between the sampling device and the two-way sampling pump 16. Blow valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com