Flaky workpiece transfer tool with positioning structure and device

A sheet-shaped workpiece and positioning structure technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as difficulty in maintaining the state of the tape, inconvenience of the clamping mechanism to lift the tape and fit, affect the state of the tape and transfer efficiency, etc., to achieve structural Simple and effective, convenient transfer operation, convenient processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

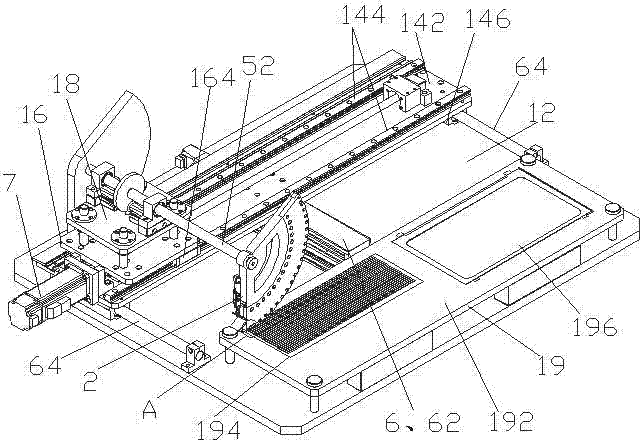

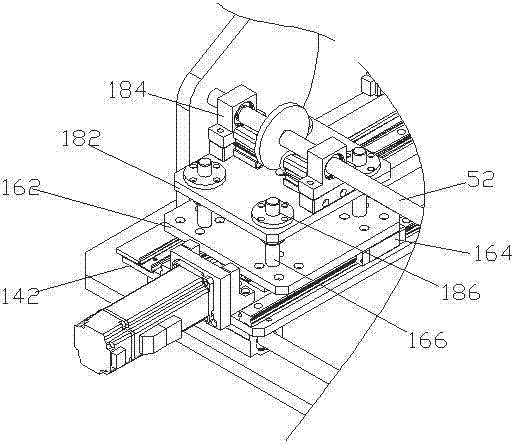

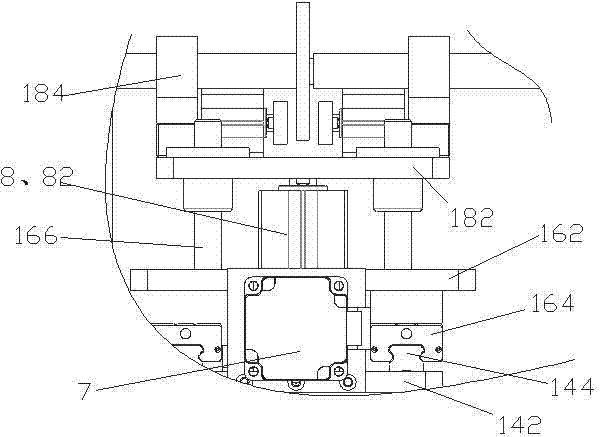

[0042] Such as Figure 1-8 As shown, a tool for transferring sheet-shaped workpieces with a positioning structure is specifically suitable for a strip-shaped sheet-shaped workpiece, which includes a working head 2, and the working head 2 has an arc-shaped working surface 242. When rotating around the axis, each part in the bending direction can successively capture the parts tangent to itself on the workpiece and gradually release the corresponding parts of the workpiece. Part 3 has a positioning head 32 capable of pressing at least part of the workpiece on a target plane and withdrawing it.

[0043] The working head 2 is fan-shaped, and forms an arc-shaped working surface 242 on the arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com