Grain collection device

A collection device and grain technology, applied in the field of machinery, can solve the problems of large fan size, many parts, long process, etc., and achieve the effect of improving production efficiency, fewer parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

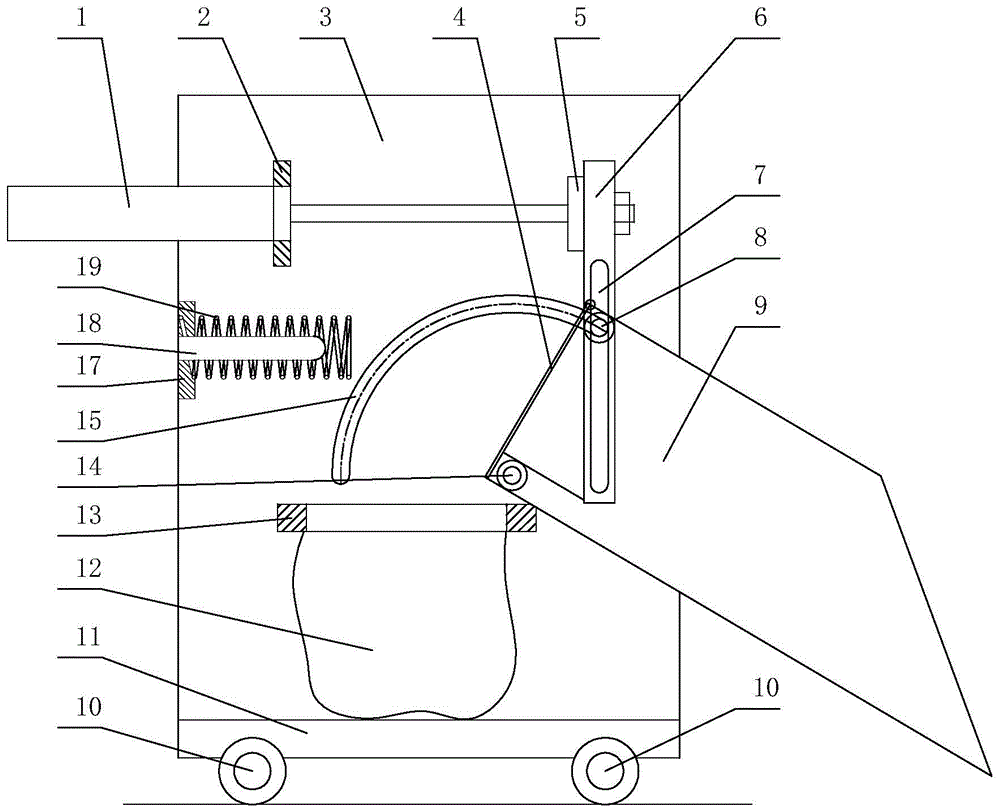

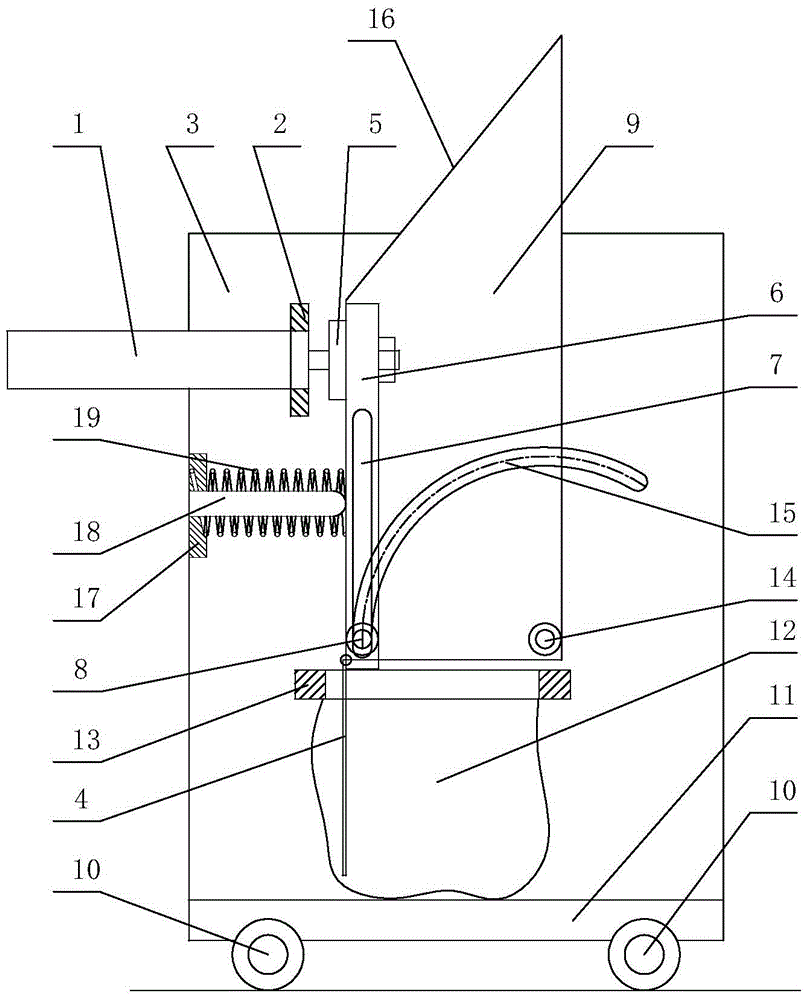

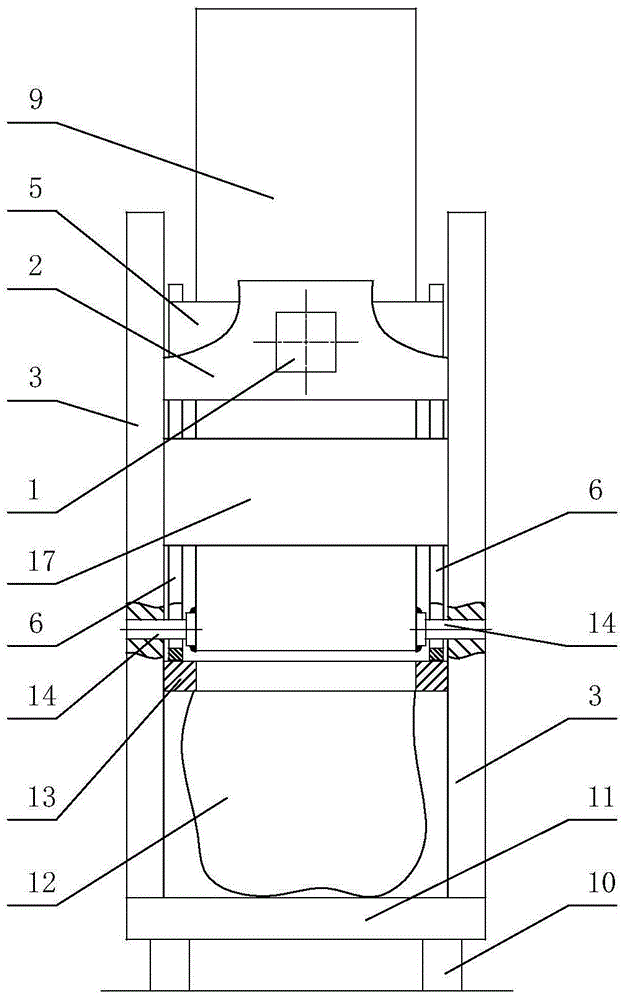

[0026] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0027] Depend on Figure 1 to Figure 3 It can be seen from the schematic structural diagram of the grain collection device of the present invention that it includes a movable base 11, a rack plate 3, a bag fixing device 13 for sleeved grain bags 12, a hopper 9, a hopper drive device and a hopper buffer device. . There are two rack plates 3, and the lower end of each rack plate 3 is fixedly connected to the edge of the movable base 11; the bag fixing device 13 is connected between the two rack plates 3 and is located in the rack. The middle of the plate 3 in the vertical direction. The hopper 9 is rotatably attached to the two frame plates 3 and the rotatable attachment point is located above the edge of the bag holder 13 . The hopper driving device includes a driving cylinder 1, two vertical sliding rods 6, a sliding rod connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com