Composite nonwoven fabric for desiccant packaging and preparation method thereof

A non-woven fabric and desiccant technology, applied in the field of composite non-woven fabric and its preparation, can solve the problems of high price, high cost, and inability to adapt, and achieve non-brittle, high dust-proof performance, dense fiber structure, and breathable good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Choose 40g / m 2 PET spunbond nonwoven fabric, 35g / m 2 PET / PE long fiber spunbonded nonwoven fabric;

[0034] 2. On the non-woven fabric hot-press laminating machine, select the temperature of 110°C, and directly press the bumps to roll and hot-roll to make 75g / m 2 Wiener Type I (T).

Embodiment 2

[0036] 1. Use 30g / m 2 PET spunbond nonwoven fabric, 25g / m 2 PP / PE long fiber spunbonded nonwoven fabric;

[0037] 2. On the non-woven hot-press laminating machine, select the temperature of 150°C, and directly press the bumps to roll and hot-roll to make 55g / m 2 Wiener Type I (P).

Embodiment 3

[0039] 1. Choose 40g / m 2 PET spunbond nonwoven fabric, 25g / m 2 PET / PE long fiber spunbonded nonwoven fabric;

[0040] 2. On the non-woven fabric hot-press laminating machine, select the temperature of 130°C, and directly press the convex point roll to make 65g / m 2 Wiener Type I (T).

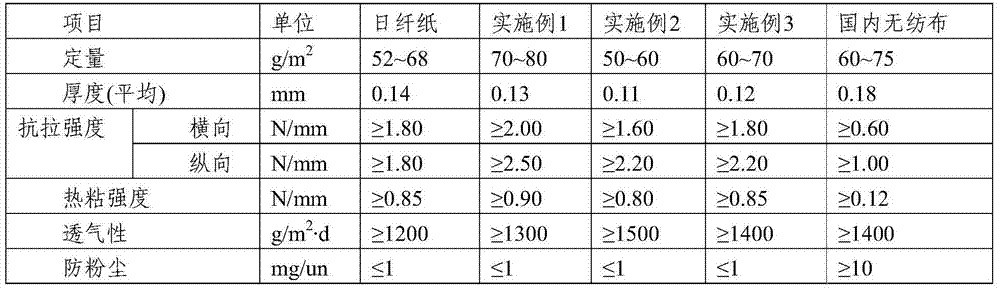

[0041] performance comparison

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com