Multi-joint robot for mounting and demounting ground wires

A multi-joint robot and grounding wire technology, applied in the field of electric power, can solve the problems of long time-consuming assembly and disassembly of grounding, life risks, large economic losses, and large operational risks, etc., to reduce economic losses, change dangers, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

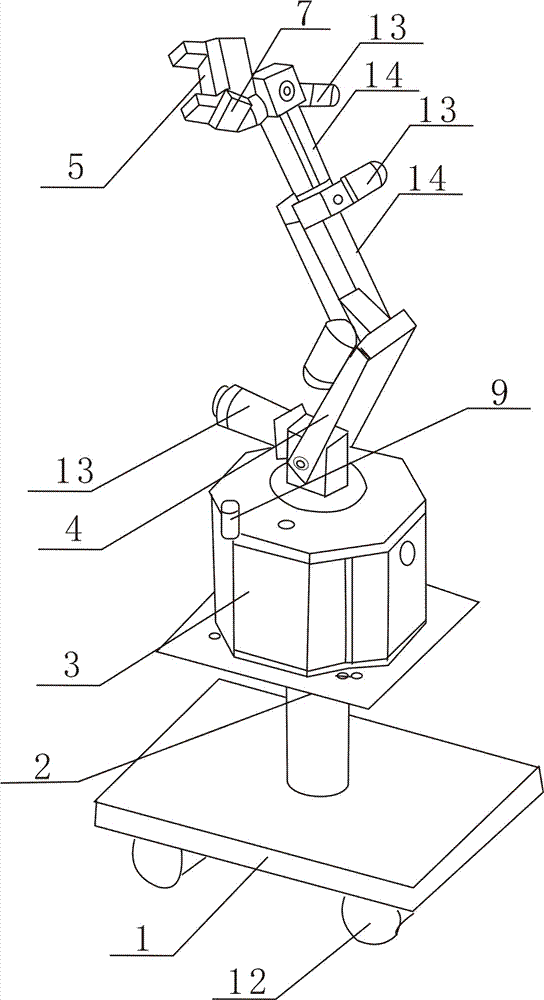

[0017] Example: such as figure 1 As shown, the multi-joint robot for assembling and disassembling the ground wire has a mobile platform 1 with rollers 12 at the bottom, and a hydraulic lifting platform 2 controlled by hydraulic pressure is installed on the mobile platform 1 . A control cabinet 3 is fixed on the hydraulic lifting platform 2, and the control cabinet 3 is connected to a multi-joint arm 4 through a bearing. The end of the multi-joint arm 4 is connected with a wire hanging fixture 5 . The multi-joint arm 4 is composed of several articulated arms 14 connected in series, the articulated arms are connected by bearings, and the rotation shaft of each articulated arm is connected with a motor 13 .

[0018] The control cabinet 3 is provided with a platform control system, see figure 2 , the control system includes a processor module 6, an image collector 8, a position sensor 7, a motor control module 11 and a WIFI module 9. The processor module 6 includes a visual pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com