Water-soluble surfactant composition and ink composition containing the composition

A surfactant and composition technology, applied in the field of water-soluble surfactant composition, can solve problems such as insufficient, poor fluid characteristics, and incapable of high-speed coating, and achieve practical benefits, small contact angle, and low dynamic surface tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

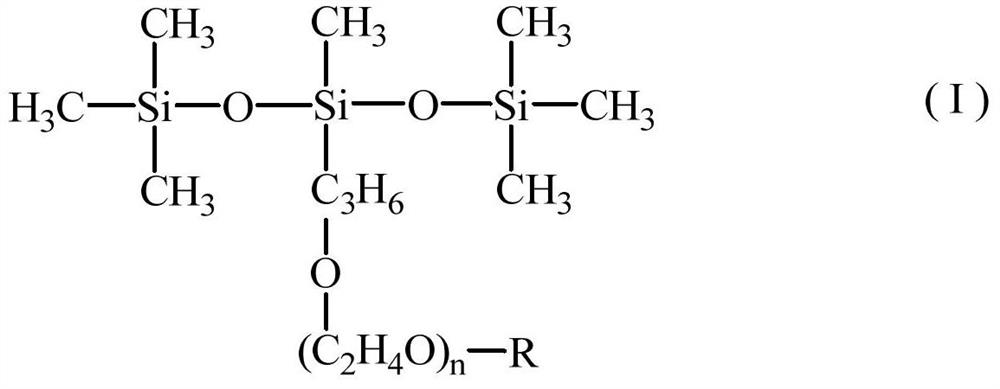

Method used

Image

Examples

Embodiment 1

[0061] 80 parts of (A-1) heated to 50° C. were put into a container with a blade stirrer, 10 parts of propylene glycol and 10 parts of water were slowly added, and stirred for 1 hour to obtain a surfactant composition (hereinafter referred to as called M-1).

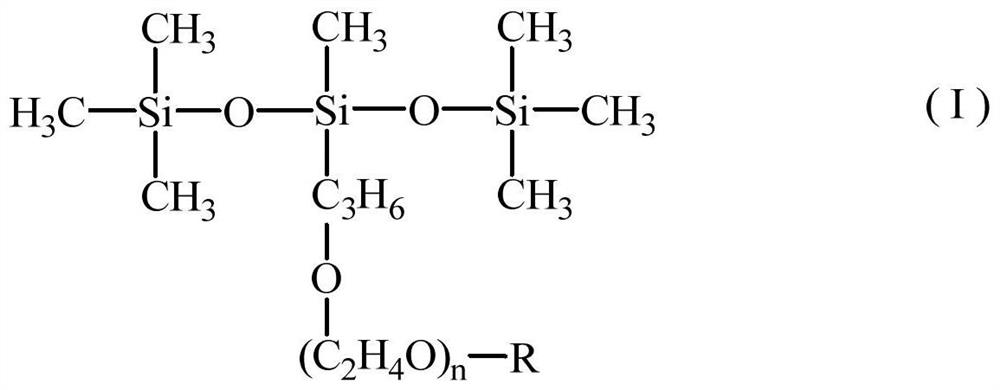

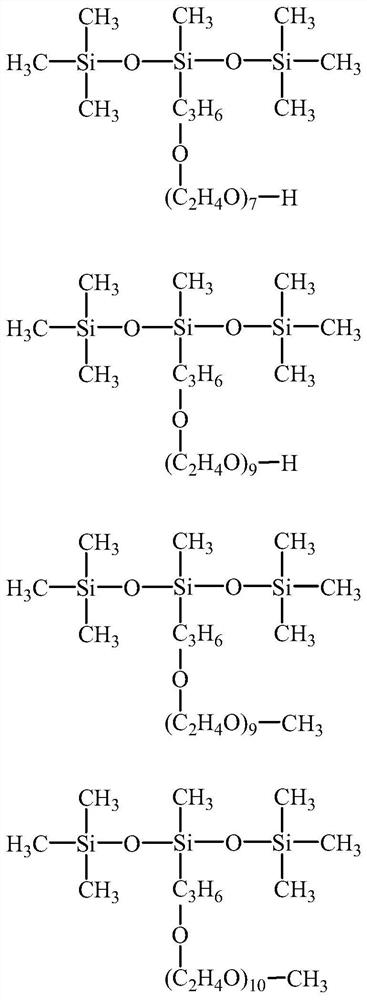

[0062] 【Chemical 4】

[0063]

Embodiment 2~4、 comparative example 1~9

[0065] Surfactant compositions M-2 to M-13 were obtained in the same manner as in Example 1 with the compounding compositions shown in Table 1.

[0066] 【Chemical 5】

[0067]

[0068] 【Chemical 6】

[0069]

[0070] 【Table 1】

[0071]

[0072] In addition, the measurement of each physical property was performed as follows. The results are shown in Table 2.

[0073]

[0074] The appearance of the aqueous solution and the presence or absence of insoluble matter were checked.

[0075] ○: The aqueous solution is transparent, and no insoluble matter is found

[0076] △: The aqueous solution was cloudy, but no insoluble matter was found

[0077] ×: A part of insoluble matter was found

[0078]

[0079]The dynamic surface tension at 1 Hz and 10 Hz of a 0.1% aqueous solution of the surfactant composition was measured using a bubble pressure type dynamic surface tensiometer Kruss BP-100 manufactured by KRUSS Corporation.

[0080]

[0081] The contact angle after dr...

Embodiment 5

[0086] As the ink, after slowly adding 5 parts of Kara Bradke S170 (manufactured by Degussa Co., Ltd.) as a black pigment to 70 parts of ion-exchanged water while stirring with a blade mixer, add 1 part of surfactant composition M-1, 10 1 part polyethylene glycol (molecular weight 200), 15 parts glycerin, and after stirring for 1 hour, a black ink composition (hereinafter referred to as ℓ-1) was obtained.

[0087] Furthermore, a magenta pigment (C.I. Pigment Red 122), a cyan pigment (C.I. Pigment Blue 15:3), and a yellow pigment (C.I. Pigment Yellow 74) were used instead of the above-mentioned black pigment, and magenta (C.I. Pigment Yellow 74) was produced in the same manner as above. M), cyan (C), yellow (Y) ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com