Bicycle

A bicycle and edge technology, applied in vehicle components, transportation and packaging, rider driving, etc., can solve the problems of weight, disadvantages, and affecting the mileage of bicycle driving devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

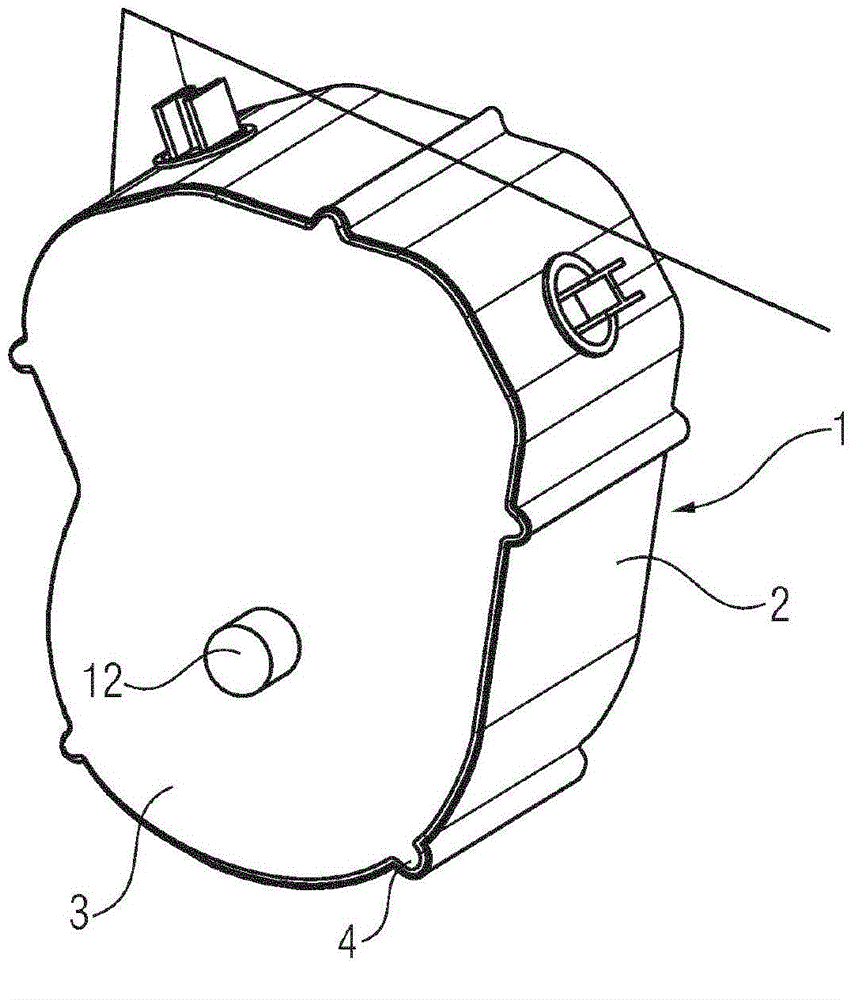

[0023] figure 1 The housing 1 of an electric bicycle drive of a bicycle is shown, the bicycle frame being shown schematically and briefly. The housing comprises a surrounding edge 2 which is covered by two covers 3 , only the front cover 3 being visible in the drawing. The cover 3 is screwed to the surrounding edge 2 by means of a screw connection 4 not shown in detail.

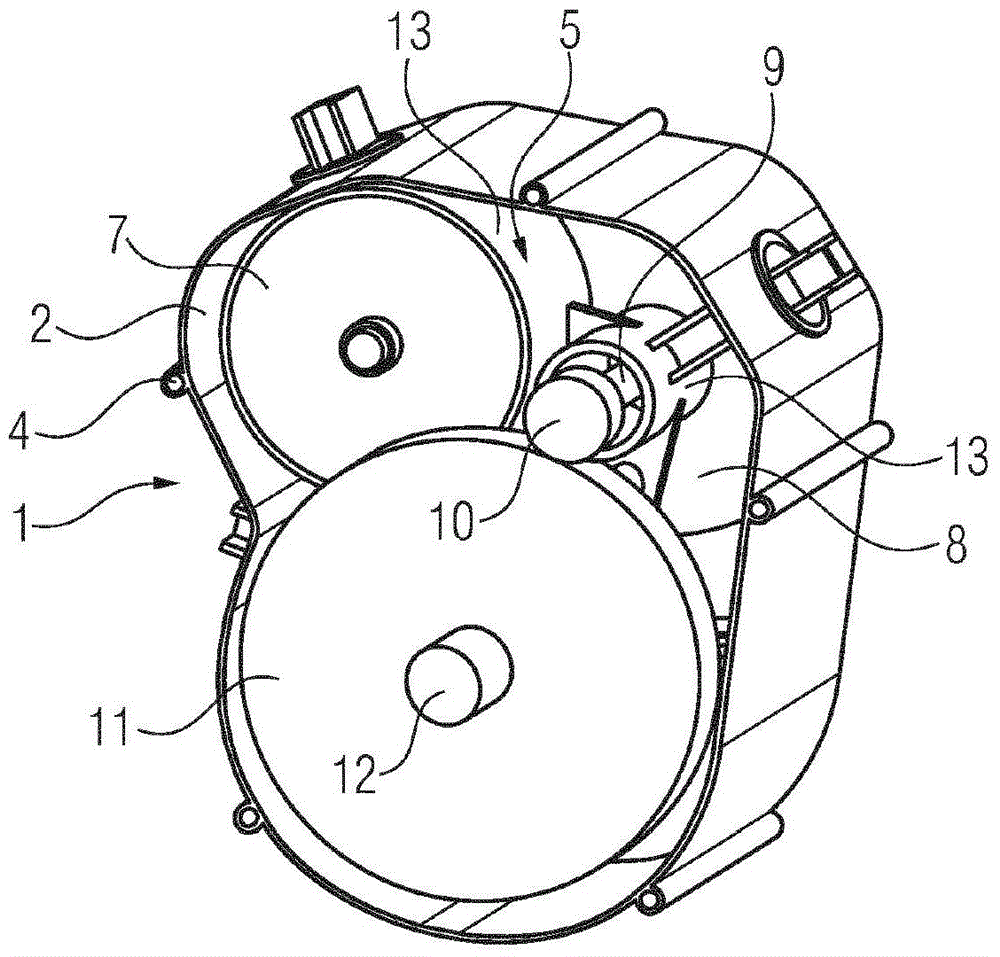

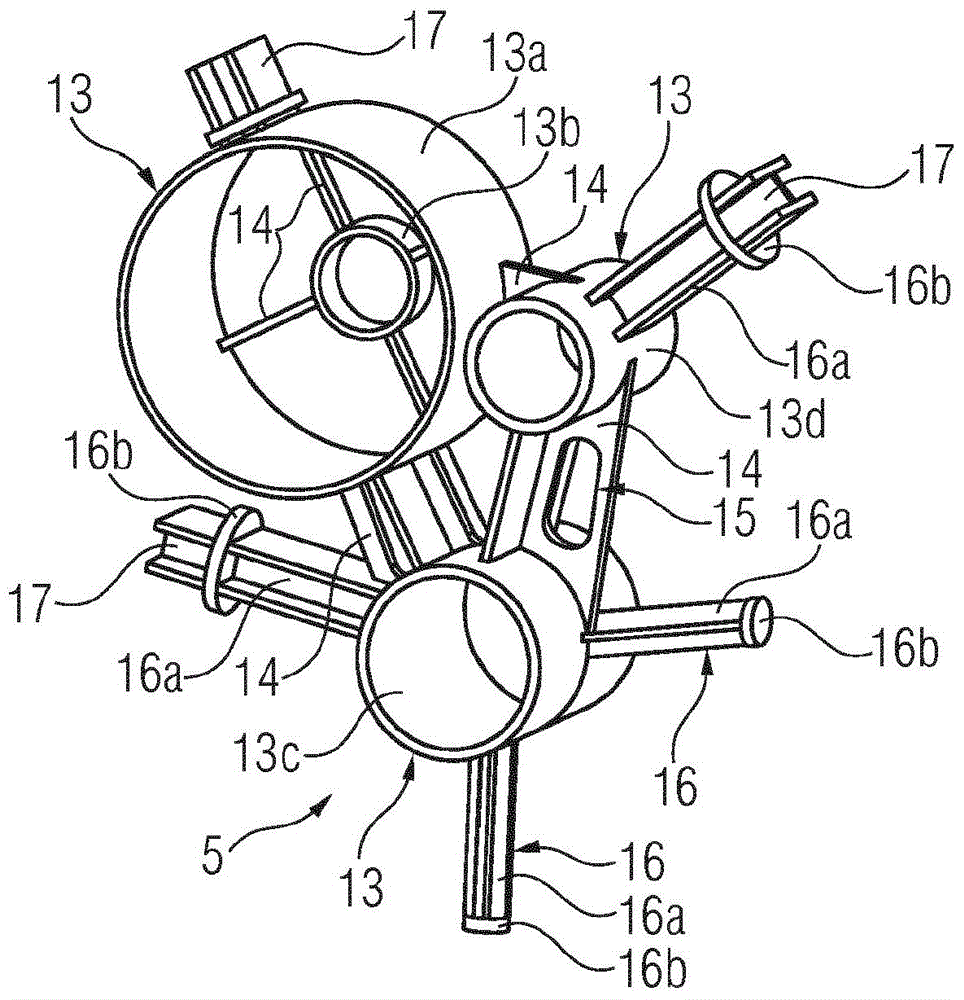

[0024] in accordance with figure 2 A bracket 5 is provided in the housing 1 of the housing 1, and the bracket accommodates the inserted parts. The built-in part is the electric motor 7, which drives the first gear 8 via a pinion not visible on the motor shaft. The gear 8 is connected with a second gear 10 via a shaft 9 . The gear 10 meshes into a third gear 11 . The third gear wheel 11 is fitted on a crankshaft 12 which passes through the cover 3 of the housing 1 for connecting the pedal crank. The motor 7 and the shafts 9 , 12 of the gearwheels 8 , 10 , 11 are mounted in a holder 13 of the carrier 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com