Method for preventing large-area exposure of insulating frame

An insulating frame and large-area technology, applied in the shape/style/structure of winding insulation, casing/cover/support, manufacturing motor generators, etc., can solve problems such as exposure, achieve high production efficiency, and improve bonding strength , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

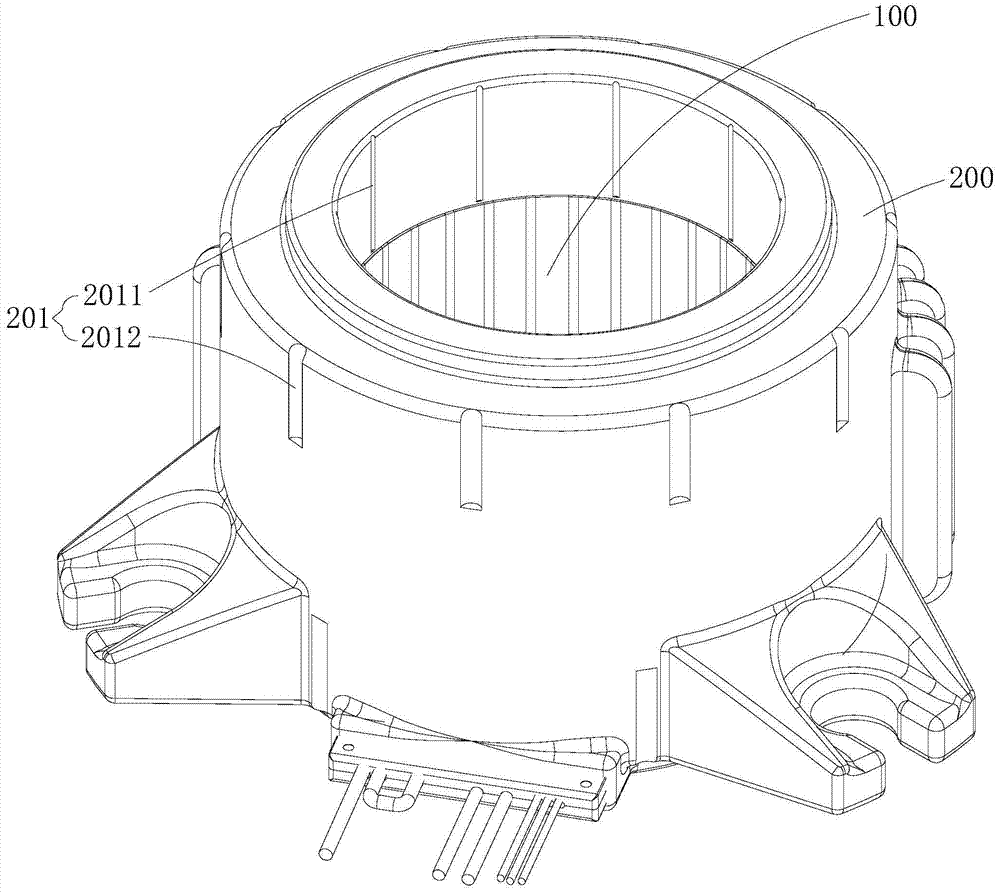

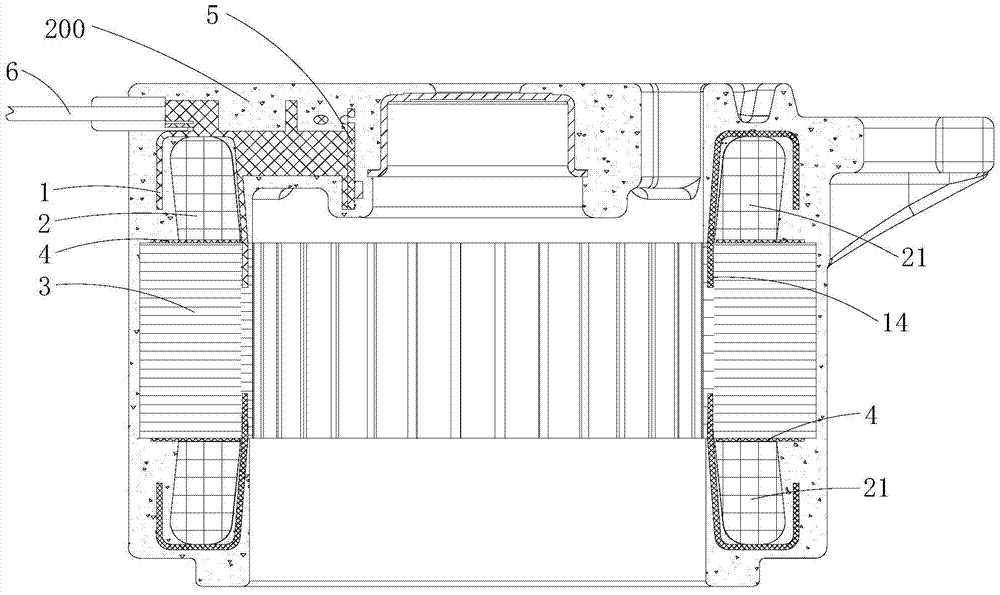

[0025] combined reference Figure 1~3 As shown, the method for preventing large-area exposure of the insulating frame provided by Embodiment 1 of the present invention specifically includes: setting several mold positioning bumps (not shown) protruding along its radial direction in the plastic sealing mold (not shown), Before plastic sealing, the stator assembly 100 is placed in the plastic sealing mold, and the mold positioning projections are pressed against the stator winding end insulating frame 1 along the radial direction of the plastic sealing mold, so that the mold positioning projections can be insulated from the stator winding end The abutting fit of the frame 1 prevents the large-area exposure of the insulating frame 1 at the end of the stator winding after plastic sealing, and after the plastic sealing is completed, a number of positioning points are formed on the plastic sealing shell 200 to match the positioning protrusions of each mold on the plastic sealing mold...

Embodiment 2

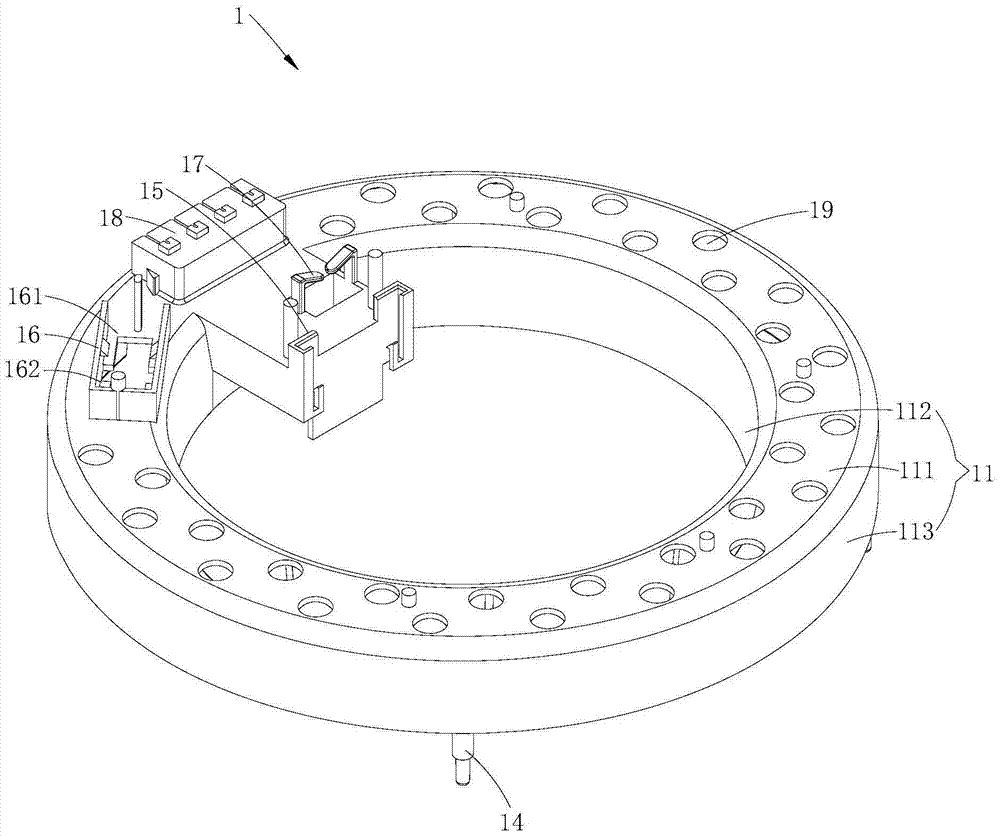

[0042] combined reference Figure 4 As shown, the method for preventing the large-area exposure of the insulating frame provided by the second embodiment of the present invention is as follows: on the insulating frame 1 at the end of the stator winding, a number of frame positioning protrusions 10 protruding along its radial direction are provided, and before plastic sealing, The stator assembly 100 is placed in the plastic sealing mold, and the frame positioning projection 10 is pressed against the plastic sealing mold along the radial direction of the plastic sealing mold, so that the stator winding end after plastic sealing can be prevented from The phenomenon that the external insulating frame 1 is exposed in a large area occurs. The method for preventing the large-area exposure of the insulating frame provided in this embodiment is to set the frame positioning protrusion 10 on the insulating frame 1 at the end of the stator winding, so that in the process of molding the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com