Stator winding end insulation frame, plastic-packaging stator assembly, and plastic-packaging motor

A stator winding and end insulation technology, which is applied to the shape/style/structure of winding insulation, the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., and can solve the problem of large-scale exposure of the insulating frame at the end of the stator winding, etc. problems, to achieve the effect of realizing automated production installation, improving the degree of automated production, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

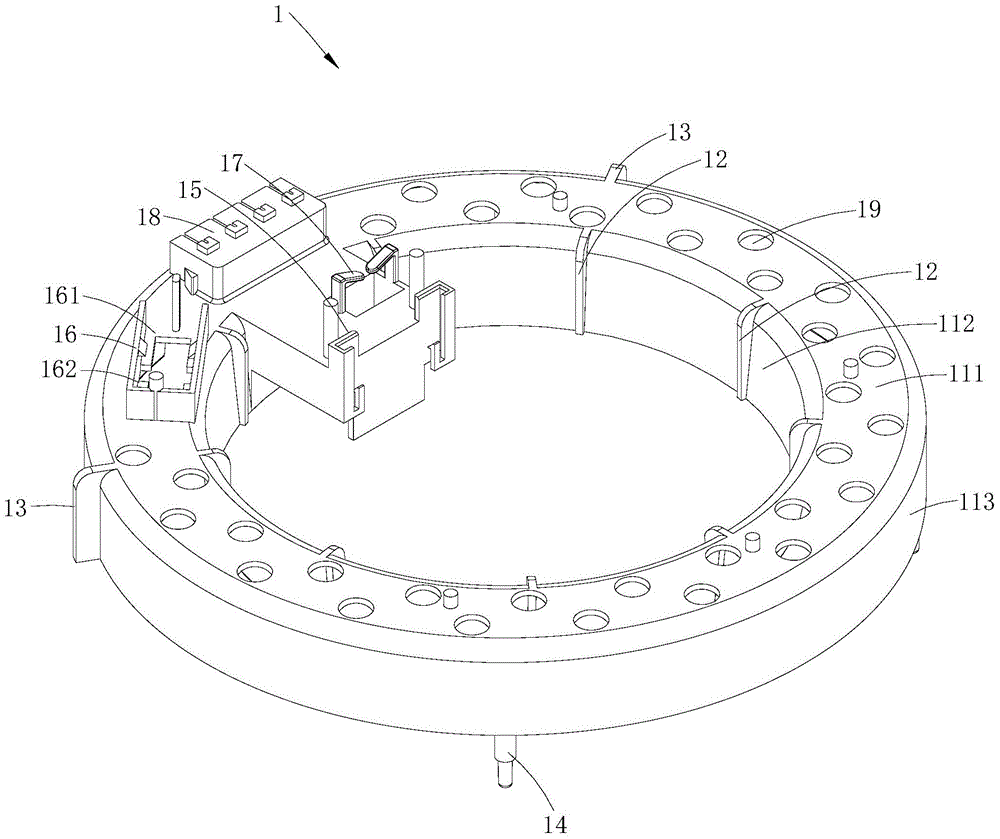

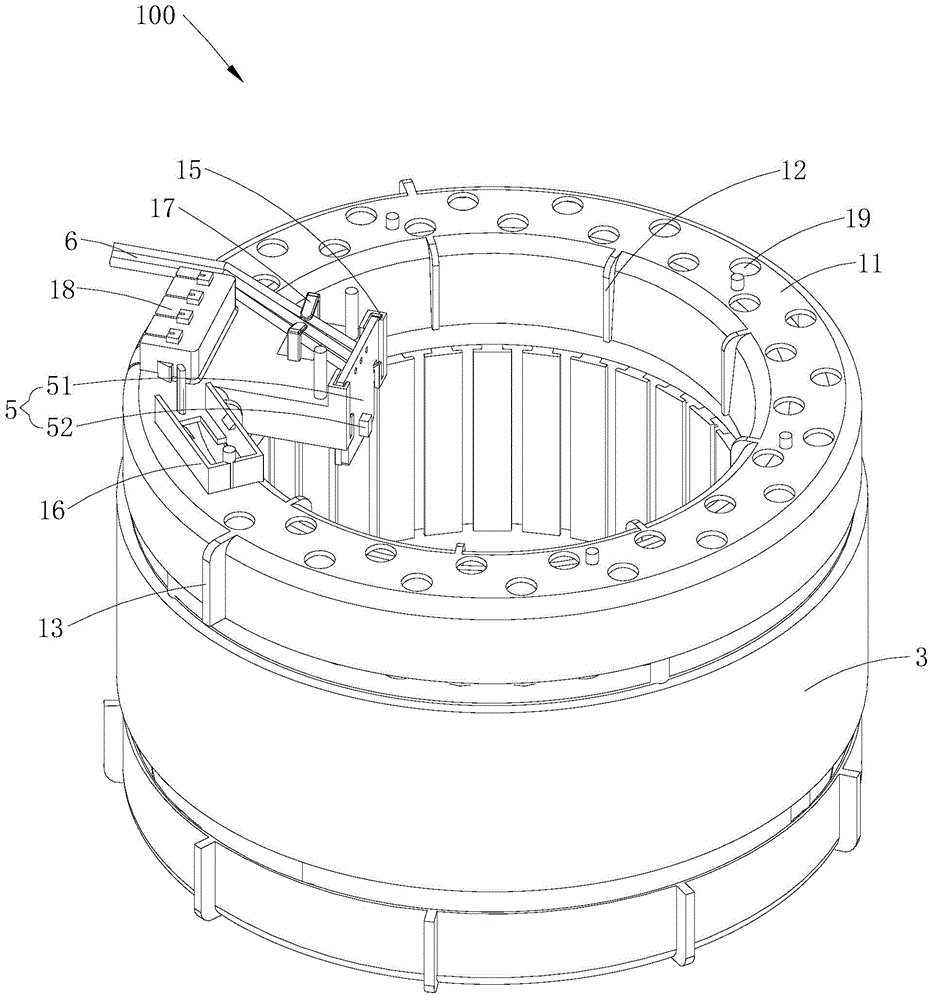

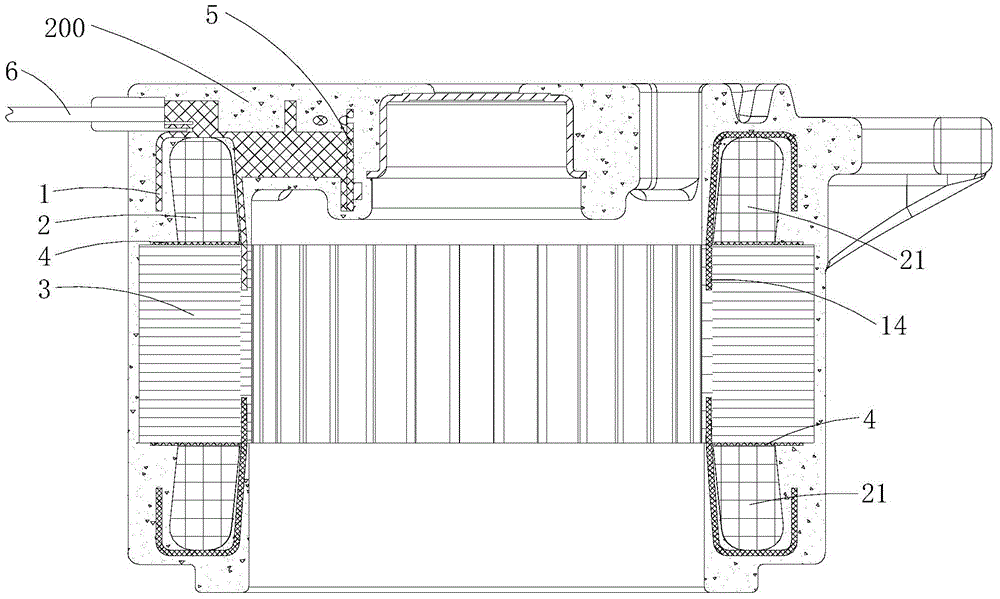

[0024] combined reference Figure 1~3 As shown, the stator winding end insulating frame 1 provided by Embodiment 1 of the present invention includes an insulating frame body 11 sleeved on the axial end 21 of the stator winding 2 along the motor axial direction, and the insulating frame body 11 includes a The annular panel 111 on one side of the stator winding 2, the inner panel 112 bent along the inner edge of the annular panel 111 and located inside the stator winding 2 along the radial direction of the motor, and the inner panel 112 bent along the outer edge of the annular panel 111 and The outer panel 113 located outside the stator winding 2 in the radial direction of the motor, the inner panel 112 is provided with several inner positioning protrusions 12 along the motor radial direction away from the outer panel 113; and / or, the outer panel 113 is located along the motor Several outer positioning protrusions 13 protrude radially away from the inner panel 112 . The stator ...

Embodiment 2

[0041] Such as Figure 4 As shown, the stator winding end insulating frame 1, the plastic-encapsulated stator assembly and the plastic-encapsulated motor provided in this embodiment are mainly different from the first embodiment in that there is no PG board installed on the stator winding end insulating frame 1 in this embodiment. Frame 15, protector mounting frame 16, lead wire fixing frame 17 and terminal box 18, that is, the stator winding end insulation frame 1 in this embodiment is not used for PG plate member 5, temperature protector, PG plate lead wire 6 and stator winding lead wires for installation and positioning. However, since the insulating frame 1 at the end of the stator winding in this embodiment is also provided with the inner positioning protrusion 12 and / or the outer positioning protrusion 13, the stator winding end insulating frame 1 of the present embodiment is used for the stator winding 2 When the axial end 21 of the stator winding is insulated, it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com