A solid wire protection device for watertight electric wire butt joint sealing

A protection device and wire technology, which is applied to the installation of cables, parts of connecting devices, coupling devices, etc., can solve the problems of uneven thickness of silicone rubber, increased sealing workload, and no protective measures, so as to improve adhesion quality, The effect of reducing workload and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

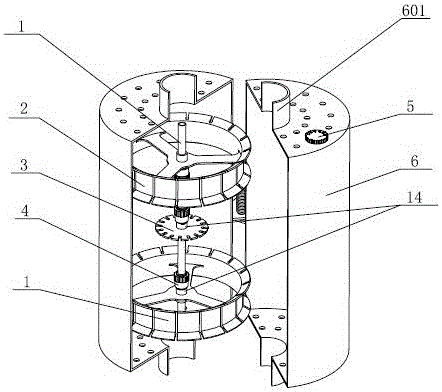

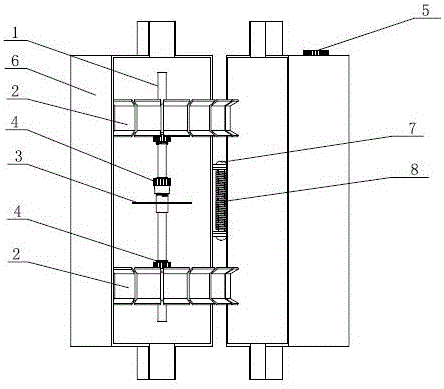

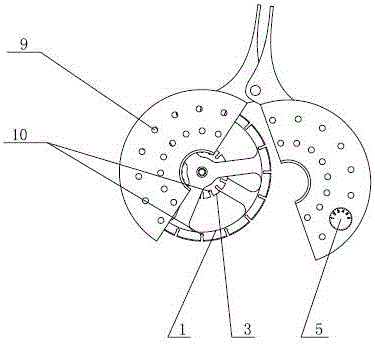

[0022] Such as figure 1 , figure 2 As shown, a wire fixing protection device for watertight wire butt joint sealing includes a round rod 1, at least one large wire fixing disk 2 and a small wire fixing disk 3 are fixed on the round rod 1 through a fastening nut 4, and on the round rod 1. A protective device is also provided on the outer periphery of the large thread-fixing reel 2 and the small thread-fixing reel 3. The protective device is composed of a pair of protective clips 6 movably connected by a rotating shaft 7, and a spring 8 is sleeved on the outer periphery of the rotating shaft 7. Such as figure 1 , figure 2 and image 3 As shown, the protective clip 6 is a semicircular cylinder with an inner cavity, and a pair of protective clips 6 form a circular cylinder when closed, and a plurality of drying holes are opened on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com