Hanger frame of fixed-steering pulley

A technology of pulleys and hangers, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of hidden dangers in operation, heavy weight of insulators, increased work intensity, etc., and achieve the effect of high efficiency, simple connection, and few connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

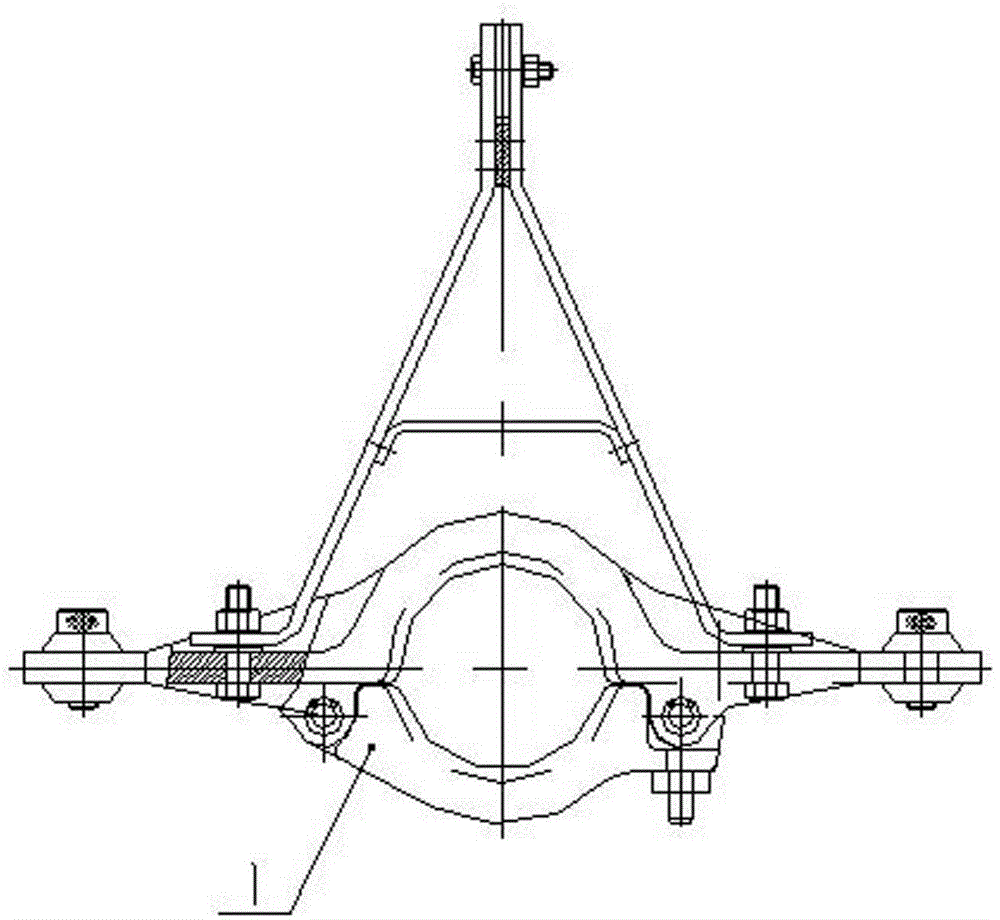

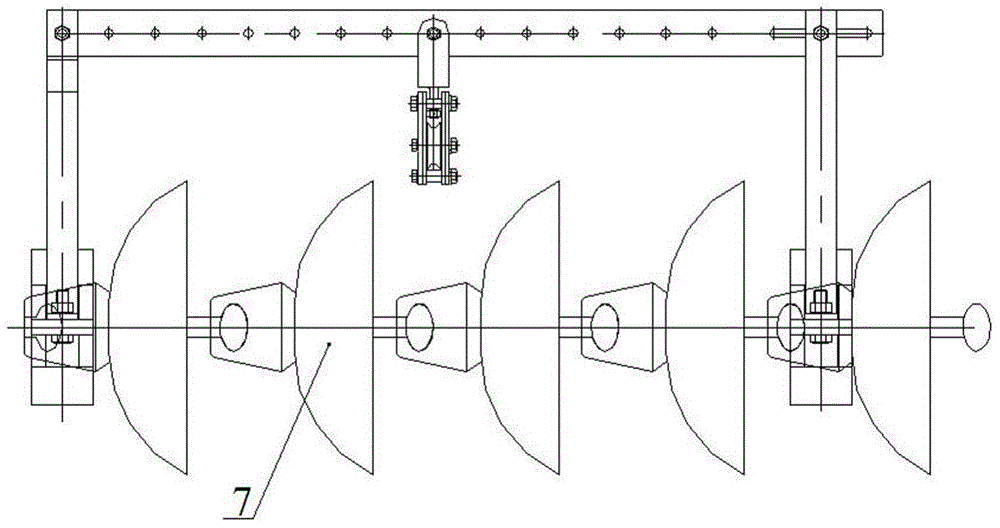

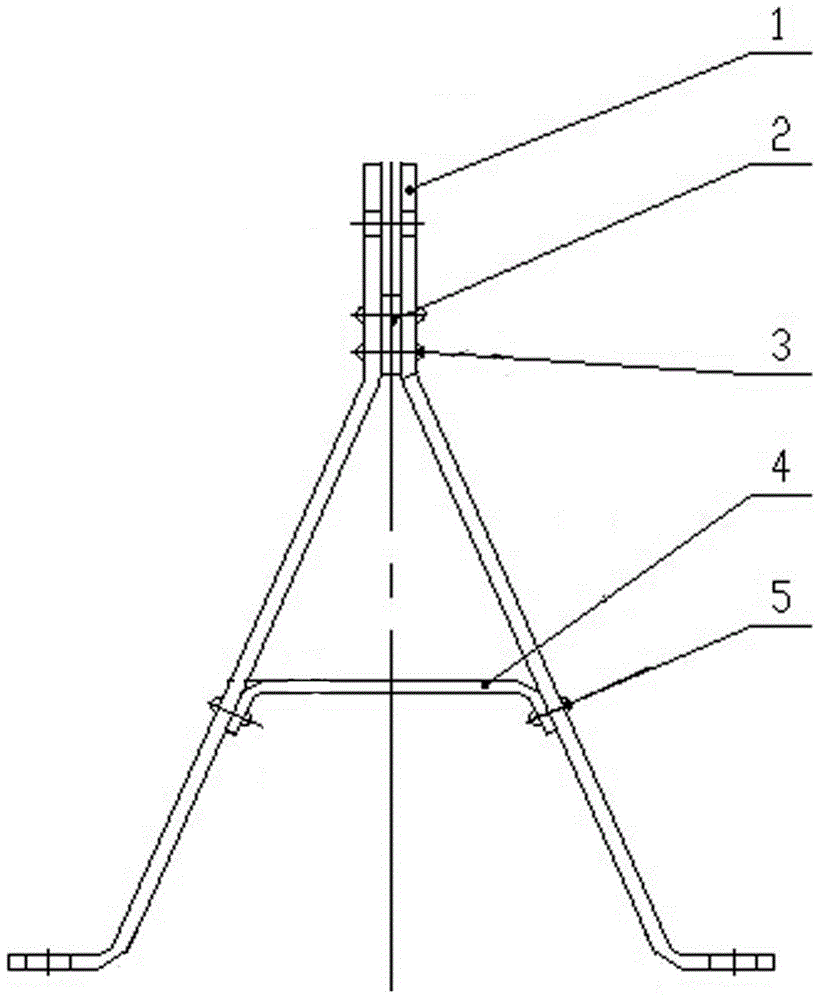

[0020] See Figure 1-Figure 5 , a hanger for fixing the steering block, the present invention is characterized in that it includes a suspension beam 8, a steering block and two groups of bracket assemblies 2; Replace the two sides of the closed fixture 1 collar of the monolithic insulator, and then connect the two brackets to the suspension beam 8 respectively; the steering block is also connected to the suspension beam 8 and is located between the two brackets; It is composed of the pulley frame 4 and the connecting fork lug 5 connected to the pulley frame 4, and the connecting fork lug 5 is connected to the hanging beam 8 by bolts; the hanging beam 8 is provided with adjustment holes in horizontal rows on the beam body; the hanging beam One end of 8 is provided with a long slot, which is used to adjust the connection between the suspension beam and the bracket assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com