Low-temperature phase change cold storage material and production method thereof

A cold storage material and low-temperature phase change technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of corrosion, low latent heat of phase change, leakage of phase change materials, etc., and achieve high cold storage density and phase change latent heat value. High, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

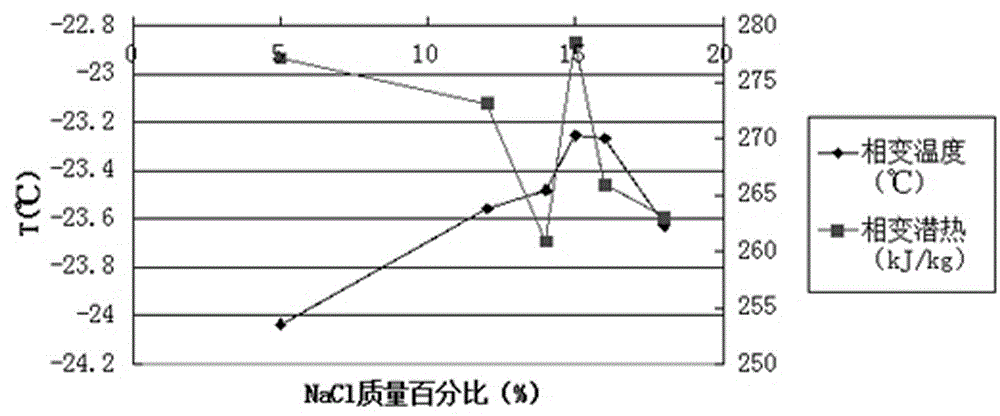

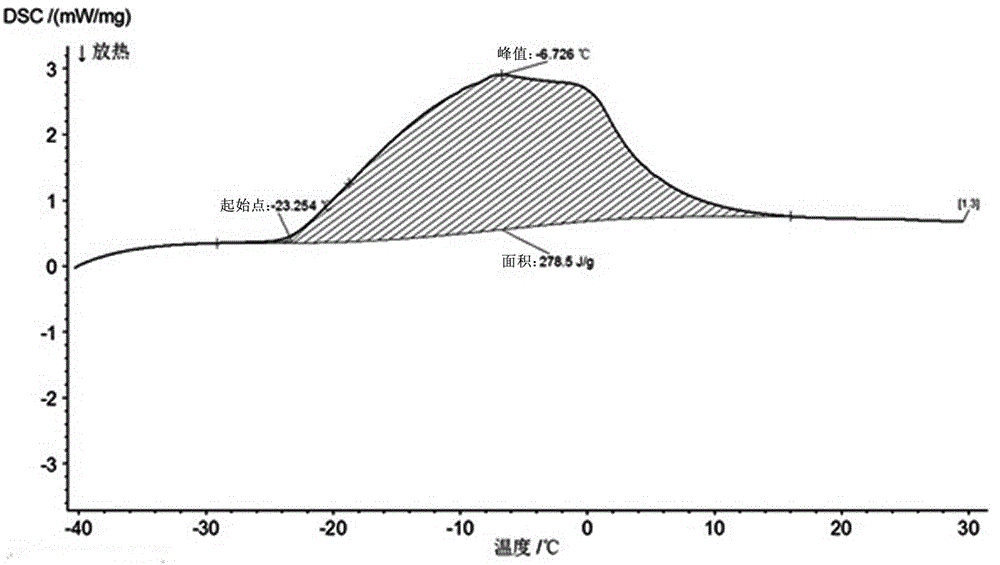

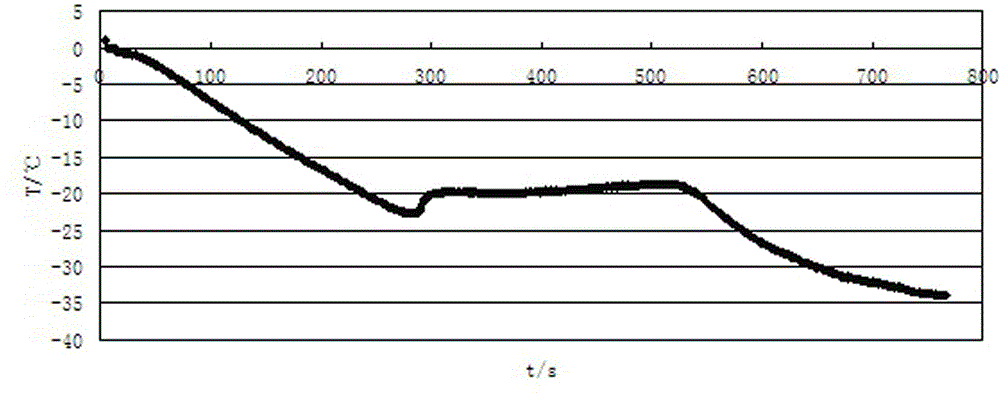

Embodiment 1

[0022] Weigh 5% by mass of sodium chloride and 17% by mass of potassium nitrate in a beaker, add 74% by mass of ordinary tap water, mechanically stir the glass rod and let it stand, then add 1% by mass at room temperature Add sodium tetraborate, 1% sodium benzoate, and 2% polyvinyl alcohol into sodium chloride-potassium nitrate aqueous solution, and use the cavitation effect of an ultrasonic oscillator to mix the above materials evenly, and obtain the required low-temperature phase change cold storage after cooling to room temperature Material.

Embodiment 2

[0024] Weigh 12% by mass of sodium chloride and 10% by mass of potassium nitrate in a beaker, add 74% by mass of ordinary tap water, mechanically stir the glass rod and let it stand, then add 1% by mass at room temperature Add sodium tetraborate, 1% sodium benzoate, and 2% polyvinyl alcohol into sodium chloride-potassium nitrate aqueous solution, and use the cavitation effect of an ultrasonic oscillator to mix the above materials evenly, and obtain the required low-temperature phase change cold storage after cooling to room temperature Material.

Embodiment 3

[0026] Weigh 14% by mass of sodium chloride and 8% by mass of potassium nitrate in a beaker, add 74% by mass of ordinary tap water, mechanically stir the glass rod and let it stand, then add 1% by mass at room temperature Add sodium tetraborate, 1% sodium benzoate, and 2% polyvinyl alcohol into sodium chloride-potassium nitrate aqueous solution, and use the cavitation effect of an ultrasonic oscillator to mix the above materials evenly, and obtain the required low-temperature phase change cold storage after cooling to room temperature Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com