A kind of seaweed oligosaccharide microecological drip irrigation fertilizer and preparation method thereof

A seaweed oligosaccharide and microecological technology, which is applied in fertilization devices, fertilizer mixtures, agriculture, etc., can solve the problems of adding a single strain, breaking the activity of endogenous substances of seaweed, and difficulty in industrialization and transformation, and achieves the enzymatic hydrolysis rate and The effect of improving extraction rate, improving plant nutritional status, and improving supply and absorption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

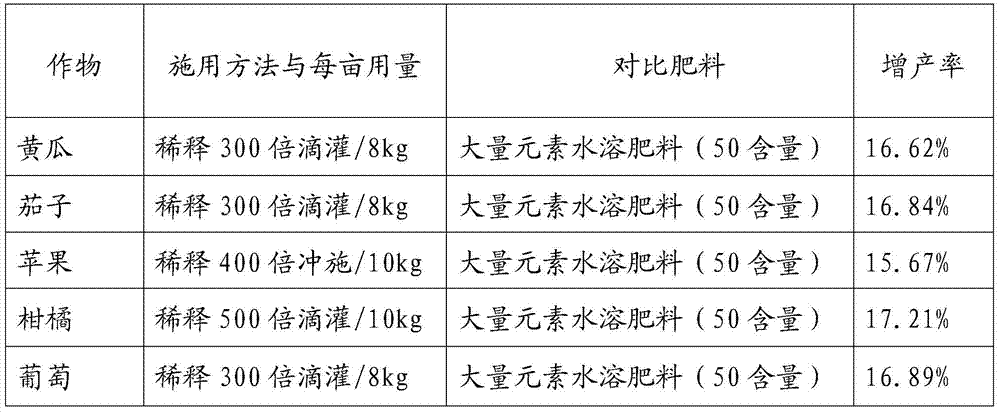

Examples

Embodiment 1

[0032] A seaweed oligosaccharide micro-ecological drip irrigation fertilizer comprises the following components by weight percentage: 20% seaweed oligosaccharide solution, 20% molasses liquid, 40% compound microbial bacterial liquid, and 20% macro, medium and trace elements.

[0033] The above-mentioned seaweed oligosaccharide solution is mixed with pulverized seaweed and water in a weight ratio of 1:4, adding 0.5% of the weight of the seaweed-water mixture with biolyzing enzyme, and adding 1% of the weight of the seaweed-water mixture. Lactic acid bacteria, At a temperature of 60°C and a pH value of 3 to 5, enzymatically hydrolyze the seaweed for 12 hours to obtain a seaweed hydrolyzate, then add potassium hydroxide solution to the seaweed hydrolyzate to adjust the pH to 8.0 to 8.5, and then pass it through a filter press. The seaweed oligosaccharide solution is obtained by pressure filtration, and the main component of the seaweed oligosaccharide in the seaweed oligosaccharid...

Embodiment 2

[0040] A seaweed oligosaccharide micro-ecological drip irrigation fertilizer comprises the following components by weight percentage: 10% seaweed oligosaccharide solution, 30% molasses liquid, 30% compound microbial bacterial liquid, and 30% macro, medium and trace elements.

[0041] The above-mentioned seaweed oligosaccharide solution is mixed with pulverized Sargassum and water at a weight ratio of 1:4, added with 0.2% by weight of biolytic enzymes in the mixture of Sargassum and water, at a temperature of 35°C and a pH value of 3 Under ~5 conditions, enzymolyze the seaweed for 16 hours to obtain the seaweed hydrolyzate, and add lactic acid bacteria accounting for 0.5% of the weight of the seaweed and water mixture during the enzymolysis, and then add potassium hydroxide solution to the seaweed hydrolyzate to adjust the pH value to 8.0 ~8.5, and then filtered through a filter press to obtain a seaweed oligosaccharide solution. The main component of the seaweed oligosaccharide...

Embodiment 3

[0048] A seaweed oligosaccharide micro-ecological drip irrigation fertilizer comprises the following components by weight percentage: 60% seaweed oligosaccharide solution, 10% molasses liquid, 20% compound microbial bacterial liquid, and 10% macro, medium and trace elements.

[0049] The above-mentioned seaweed oligosaccharide solution is mixed with pulverized kelp and water at a weight ratio of 1:7, and added with biolytic enzymes accounting for 1% by weight of the kelp-water mixture. Under certain conditions, enzymatically hydrolyze the seaweed for 24 hours to obtain a seaweed hydrolyzate, and add lactic acid bacteria accounting for 0.8% of the weight of the seaweed-water mixture during the enzymolysis, and then add potassium hydroxide solution to the seaweed hydrolyzate to adjust the pH value to 8.0-8.5 , and then filtered through a filter press to obtain a seaweed oligosaccharide solution. The main component of the seaweed oligosaccharide in the seaweed oligosaccharide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com